Membrane ultrasonic and synchronous incrustation removal ultrafiltration device and control method thereof

An ultrasonic and ultrasonic technology, applied in the field of water treatment, can solve problems such as affecting the normal operation of membrane modules, reducing membrane flux, membrane scaling, etc., to reduce the phenomenon of concentration polarization, prevent adhesion, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

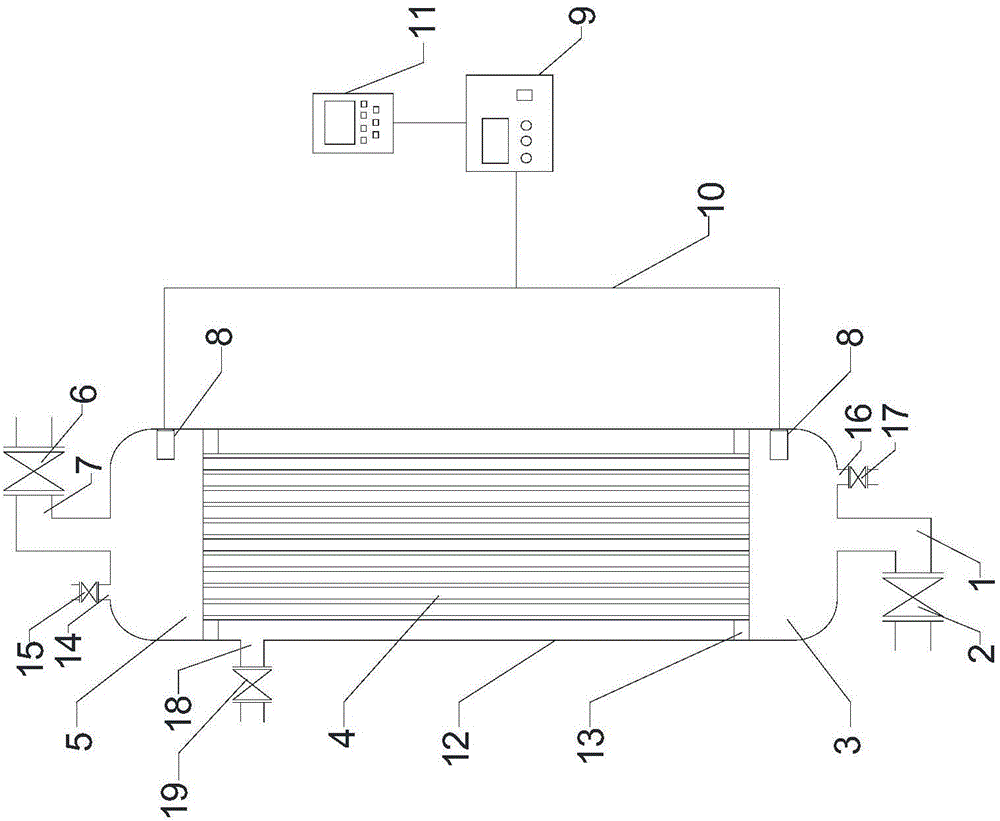

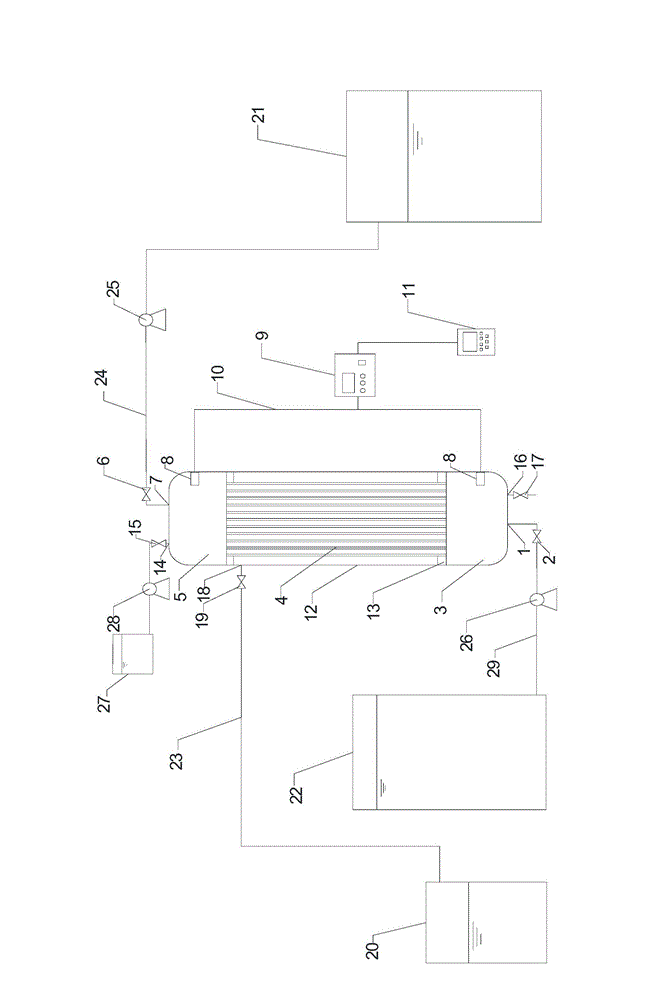

[0035] like figure 1 As shown, the ultrafiltration device is ultrasonically cleaned synchronously, and the ultrafiltration device is working normally. At this time, the cleaning water inlet valve 15 and the sewage outlet valve 17 on the ultrafiltration device are closed, and the raw water inlet valve 2, the permeate outlet valve 6 and the concentrated Liquid outlet valve 19, then start the ultrafiltration device to separate work. The raw water enters the ultrasonic contact chamber 3 at the water inlet from the raw water tank 22 through the raw water inlet pipe 29 and is powered by the raw water inlet pump 26 from the water inlet 1 through the raw water inlet valve 2, and then enters the hollow fiber membrane 4 for separation and purification. After the liquid enters the ultrasonic contact chamber 5 at the water outlet, after passing through the permeate outlet valve 6, the permeate outlet 7 is discharged into the permeate water tank 21 through the permeate outlet pipe 24 power...

Embodiment approach 2

[0038] like figure 1 As shown, the ultrafiltration device is heavily washed, and the ultrafiltration device stops working. At this time, the raw water inlet valve 2, the permeate outlet valve 6 and the concentrated solution outlet valve 19 are closed, and the cleaning water inlet valve 15 and the sewage outlet valve 17 are opened. Clean the filter device. Cleaning water and acid or oxidant cleaning agents enter the ultrafiltration device from the chemical metering tank 27 through the chemical metering pump 28 from the cleaning water inlet 14 through the cleaning water inlet valve 15. The ultrasonic transducer 8 and the ultrasonic generator 9 work continuously, and the ultrasonic Combined cleaning with acid or oxidizing agent, the cleaning waste liquid is discharged from the sewage outlet 16 and the sewage outlet valve 17, and finally the membrane flux of the ultrafiltration device is restored, and the large cleaning work of the ultrafiltration device is stopped. When the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com