Semi-solid Manufacturing Process of Submarine Ring Ribbed Cylindrical Shell by Wheel Spinning Strain Induction Method

A manufacturing process, a technology of cylindrical shells, applied in the field of semi-solid manufacturing process of wheel spinning strain induction method, can solve the problems of shrinkage, low part qualification rate, coarse grain size, etc., and achieve fine microstructure grains, The effect of complete metal streamline and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

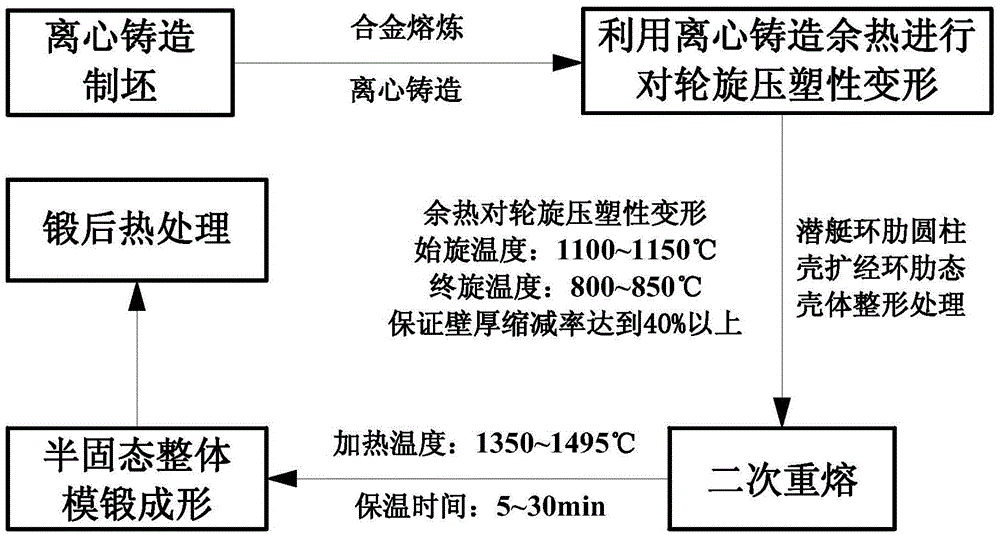

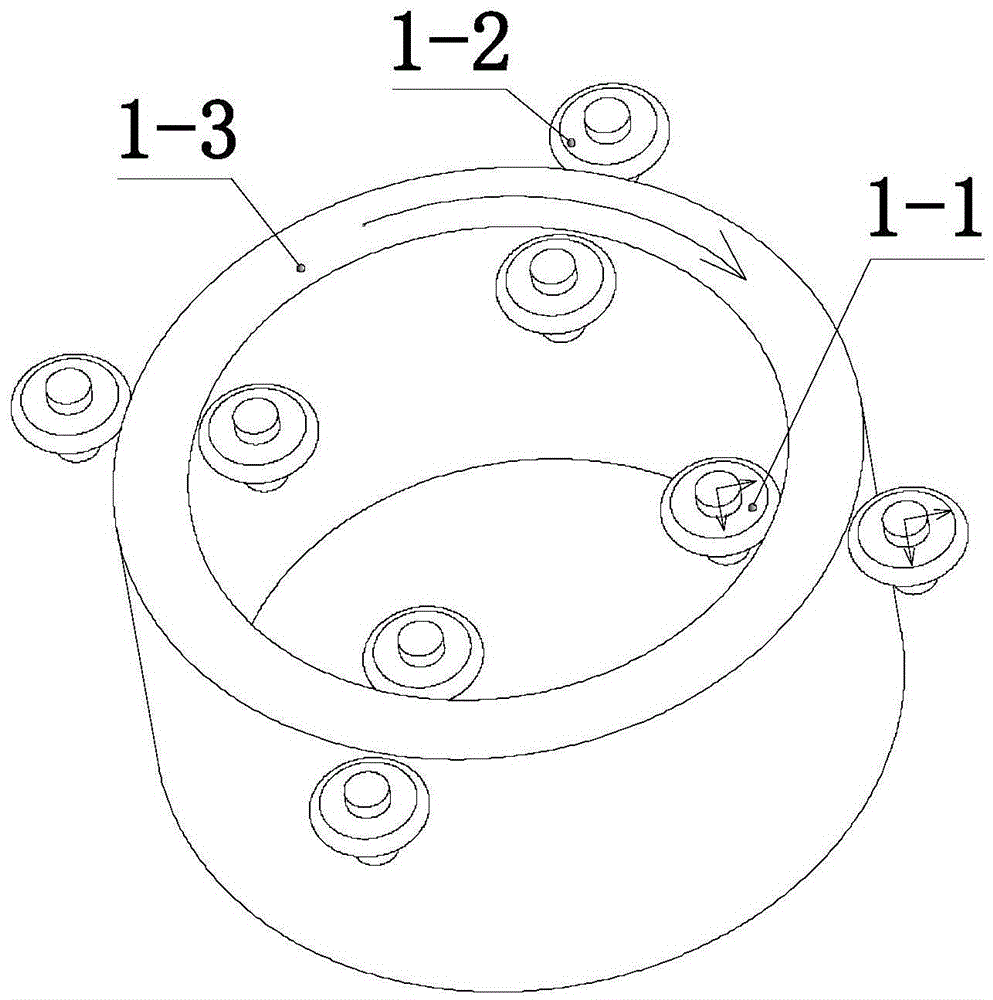

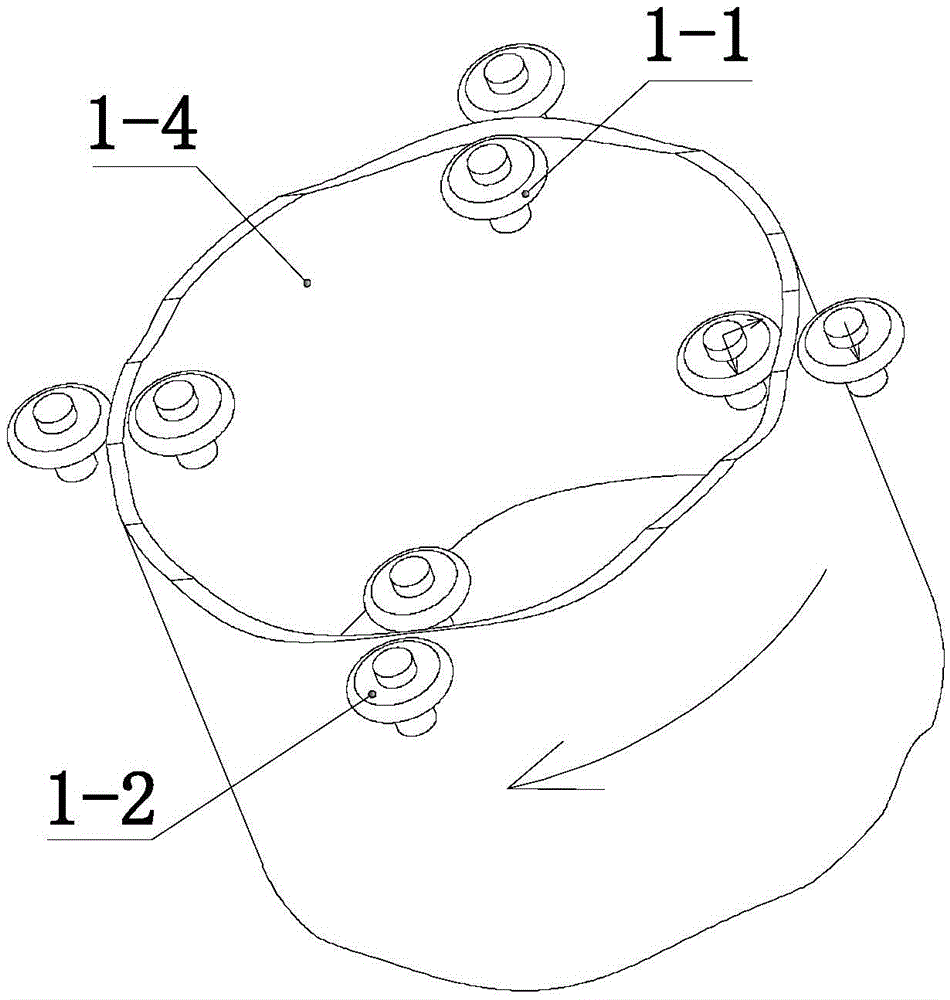

[0028] refer to figure 1 , the semi-solid manufacturing process of the wheel-spinning strain-induced method of the submarine ring-ribbed cylindrical shell, including the following steps:

[0029] 1) Centrifugal casting billet: first, put the prepared 45# steel material into the medium frequency induction melting furnace for melting, the melting temperature is above 1600 ℃, and keep it warm for 10-20 minutes for refining and degassing; then the obtained molten steel The temperature is stably controlled at 1500-1550°C and poured into the centrifugal casting equipment, and the as-cast shell of the submarine ring-ribbed cylindrical shell is prepared by the centrifugal casting process;

[0030] 2) Using the residual heat of centrifugal casting to carry out the plastic deformation of the counter-wheel spinning: through the counter-wheel spinning process, the as-cast shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com