Hydrophility anti-pollution polyamide composite reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-pollution technology, applied in the field of water treatment, can solve the problems of inability to form a hydrophilic coating, low activity, limited amount of active groups, etc., and achieve good hydrophilicity, anti-pollution ability, and graft density. The effect of high and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

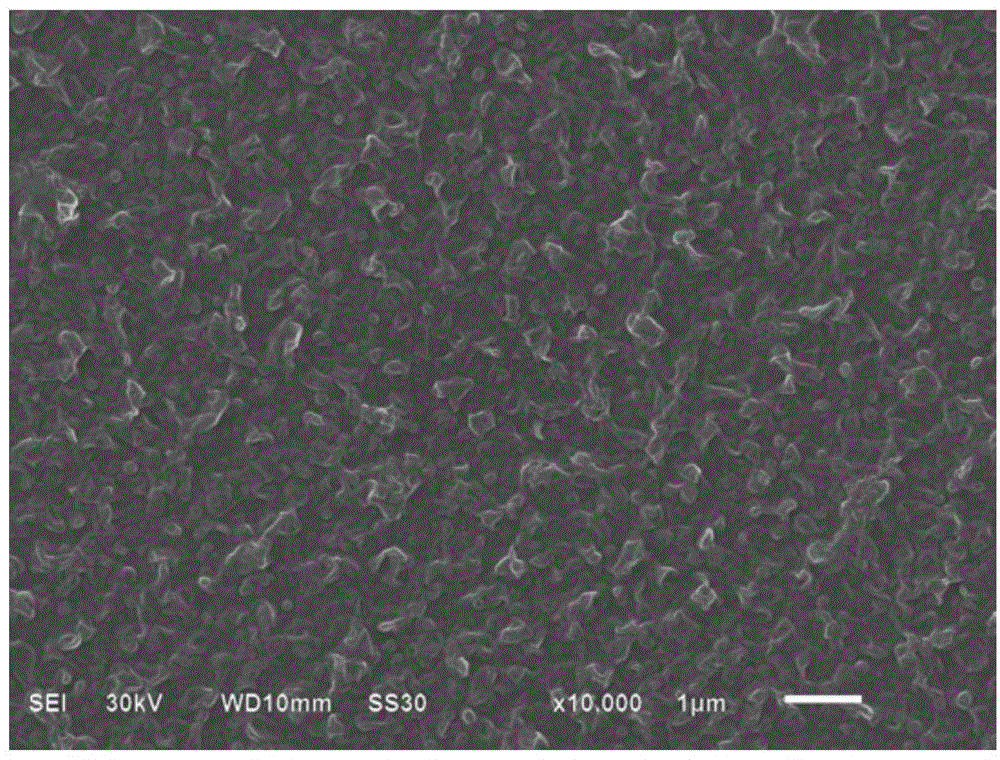

Image

Examples

Embodiment 1

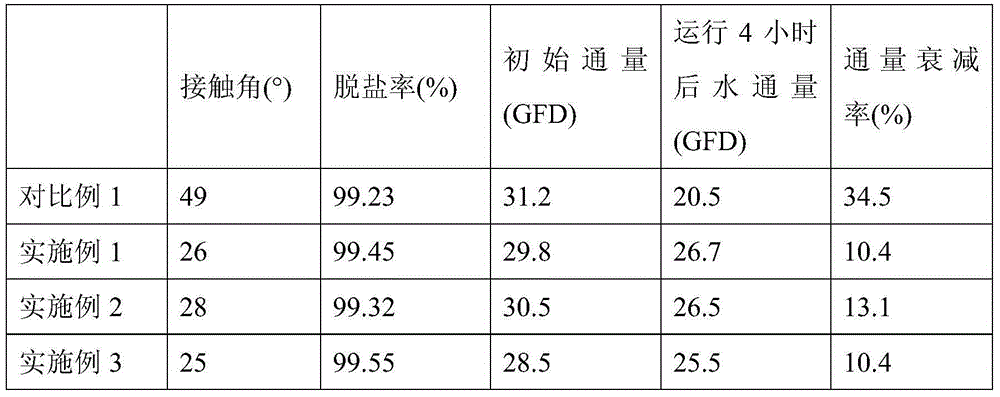

[0024] With the cross-linked polyamide composite reverse osmosis membrane of comparative example 1 as the cross-linked polyamide composite reverse osmosis membrane to be grafted;

[0025] Rinse the surface of the cross-linked polyamide composite reverse osmosis membrane (cross-linked polyamide layer) to be grafted with deionized water, then purge the membrane surface with nitrogen to no droplets; prepare an aqueous ammonium persulfate solution containing a mass concentration of 0.07%, The surface of the cross-linked polyamide composite reverse osmosis membrane to be grafted was contacted with the above-mentioned initiator solution for 7 minutes, and then the membrane surface was purged with nitrogen until there were no droplets; (HEMA) aqueous solution, contact the surface of the cross-linked polyamide composite reverse osmosis membrane containing the initiator with the above solution for 10 minutes, heat treatment at 75°C to obtain a hydrophilic anti-pollution polyamide compos...

Embodiment 2

[0028] The preparation method of the hydrophilic anti-fouling polyamide composite reverse osmosis membrane is the same as that of Example 1, but the contact time between the surface of the cross-linked polyamide composite reverse osmosis membrane containing the initiator and the monomer solution is 5 minutes.

[0029] The test method is the same as that of Comparative Example 1, and the obtained results are shown in Table 1.

Embodiment 3

[0031] The preparation method of the hydrophilic anti-fouling polyamide composite reverse osmosis membrane is the same as that of Example 1, but the contact time between the surface of the cross-linked polyamide composite reverse osmosis membrane containing the initiator and the monomer solution is 20 minutes.

[0032] The test method is the same as that of Comparative Example 1, and the obtained results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com