Orally disintegrating tablet containing fresh ginseng active extract and preparation method thereof

A technology of extract and fresh ginseng, which is applied in the field of orally disintegrating active extract of fresh ginseng and its preparation, can solve the problems of low bioavailability and inconvenient consumption, and achieve high extraction rate, simple preparation method and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

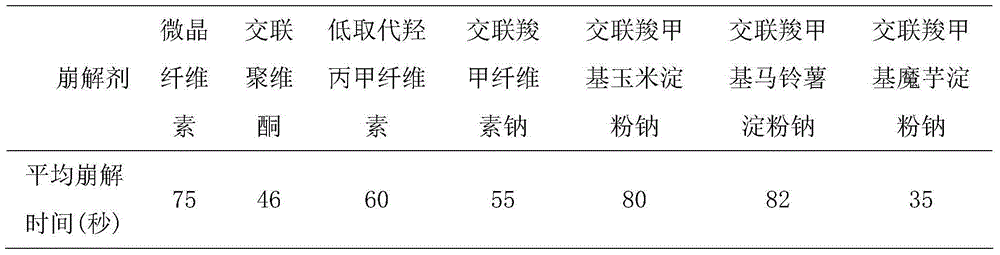

Image

Examples

Embodiment 1

[0027] Embodiment 1 preparation of fresh ginseng active extract

[0028] Take 10 kg of fresh ginseng under the forest, clean it with distilled water, crush it into 60-100 mesh particles, and use continuous countercurrent ultrasonic extraction equipment to extract under the condition of 25-35 ° C, using water as the extraction solvent, and the extract is centrifuged. Concentrate through a reverse osmosis concentrator (Hefei Zhixuan Membrane Separation Technology Co., Ltd.) to obtain a concentrate and reverse osmosis water. Reverse osmosis water is recycled as extraction solvent to realize green production. The concentrated solution is freeze-dried to obtain the active extract of fresh ginseng, and the active extract has a weight of 1.02 kg and is a brownish-yellow powder.

[0029] After testing, the content of ginsenoside Rg1 in the ginseng active extract is 3.15%, the content of ginsenoside Re is 2.2%, and the content of ginsenoside Rb1 is 2.7%. The extraction rate of ginsen...

Embodiment 2

[0030] Embodiment 2 preparation of fresh ginseng active extract

[0031] Take 50 kg of fresh ginseng under the forest, clean it with distilled water, crush it into 60-100 mesh particles, and use continuous countercurrent ultrasonic extraction equipment to extract at 25-35°C, with 10% ethanol-water as the extraction After the solvent and the extract are centrifuged, they are concentrated by a reverse osmosis concentrator (Hefei Zhixuan Membrane Separation Technology Co., Ltd.) to obtain a concentrate and reverse osmosis water. Reverse osmosis water is recycled as an extraction solvent to achieve green production. The concentrated solution is freeze-dried to obtain the active extract of fresh ginseng, and the active extract weighs 5.1 kg and is a brownish-yellow powder.

[0032] After testing, the content of ginsenoside Rg1 in the ginseng active extract was 3.11%, the content of ginsenoside Re was 2.18%, and the content of ginsenoside Rb1 was 2.61%. The extraction rate of gins...

Embodiment 3

[0033] Embodiment 3 preparation of cross-linked carboxymethyl konjac starch sodium

[0034] Add 2500g of konjac starch to 5000mL of ethanol with a volume fraction of 95%, fully stir and disperse evenly to form a starch emulsion, add 1200g of NaOH solid alkalization, and add a cross-linking agent epichlorohydrin with a starch mass of 0.12% at the same time, and place it in a 10L Erlenmeyer flask , install the reflux condenser. Pretreat at 35°C for about 20 minutes, then put in 1200g of chloroacetic acid for carboxymethylation, finish the reaction at 55°C for 2.5h, neutralize and filter while hot, and wash the obtained filter cake with ethanol with a volume fraction of 95%. Then vacuum-dried at 50°C to obtain cross-linked carboxymethyl konjac starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com