Flexible pressure sensing piece, sensor and manufacturing method of flexible pressure sensing piece

A manufacturing method and technology of sensing parts, applied in the field of sensors, can solve the problems of unrevealed intelligent connection of sensors, complicated process, high cost, etc., and achieve the effect of important application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

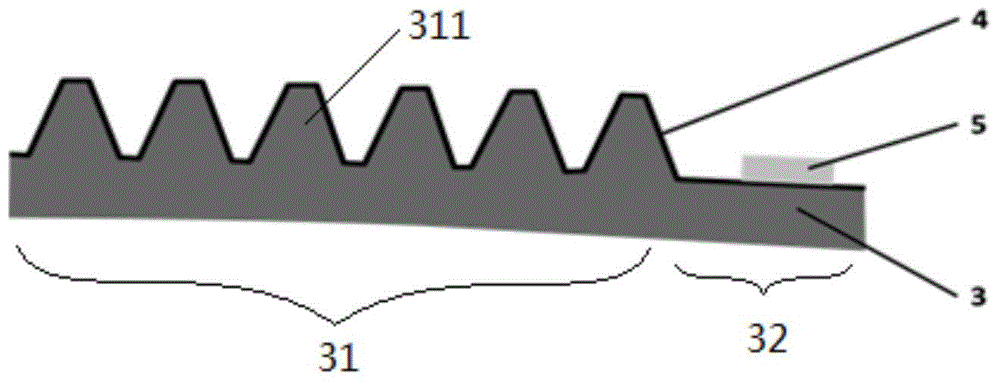

[0031] see figure 1 , the flexible pressure sensor of this embodiment includes a flexible substrate 3, and the flexible substrate 3 has a toothed structure area 31 including a plurality of toothed structures 311 and an electrode area 32, and the surface of the toothed structure area 31 and the surface of the electrode area 32 cover There is a connected conductive material layer 4 , and electrodes 5 are also provided on the surface of the conductive material layer in the electrode region 32 .

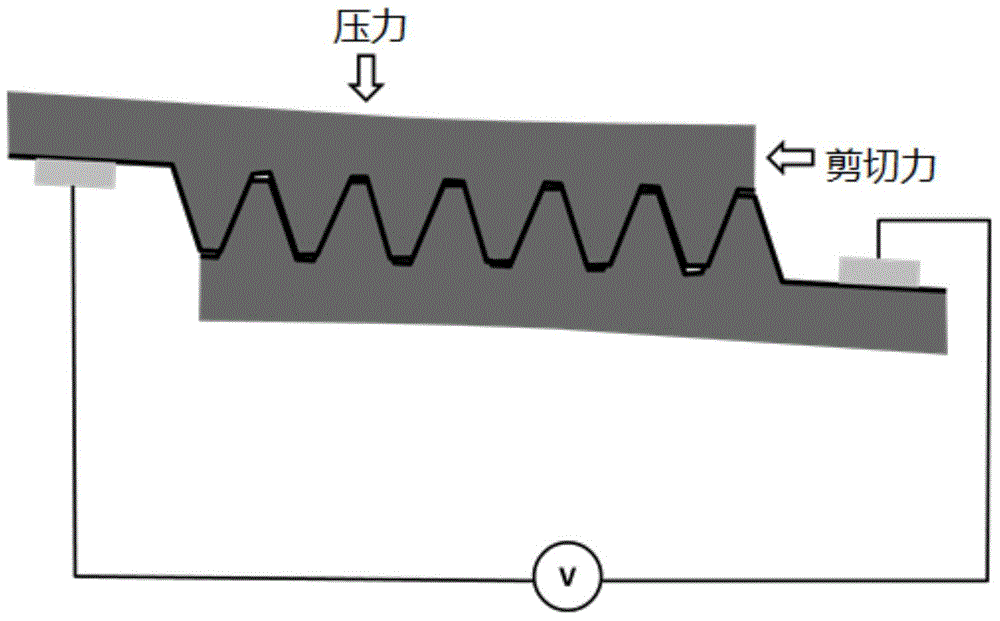

[0032] read on figure 2 , the flexible pressure sensor of this embodiment includes two figure 1 In the flexible pressure sensing element of the embodiment, the multiple tooth structures 311 of the tooth structure regions 31 of the two flexible pressure sensing elements are cross-coupled and connected to each other, that is, the tooth structure is connected to the tooth structure of another sensing element. Grooves fit, such as figure 2 As shown, so that the conductive material layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com