Method and device to test anti-scaling and anti-wax precipitation properties of tubular product

An anti-scaling and testing tube technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of lack of versatility, high test costs, high safety hazards, etc., to ensure comparability, improve test efficiency, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

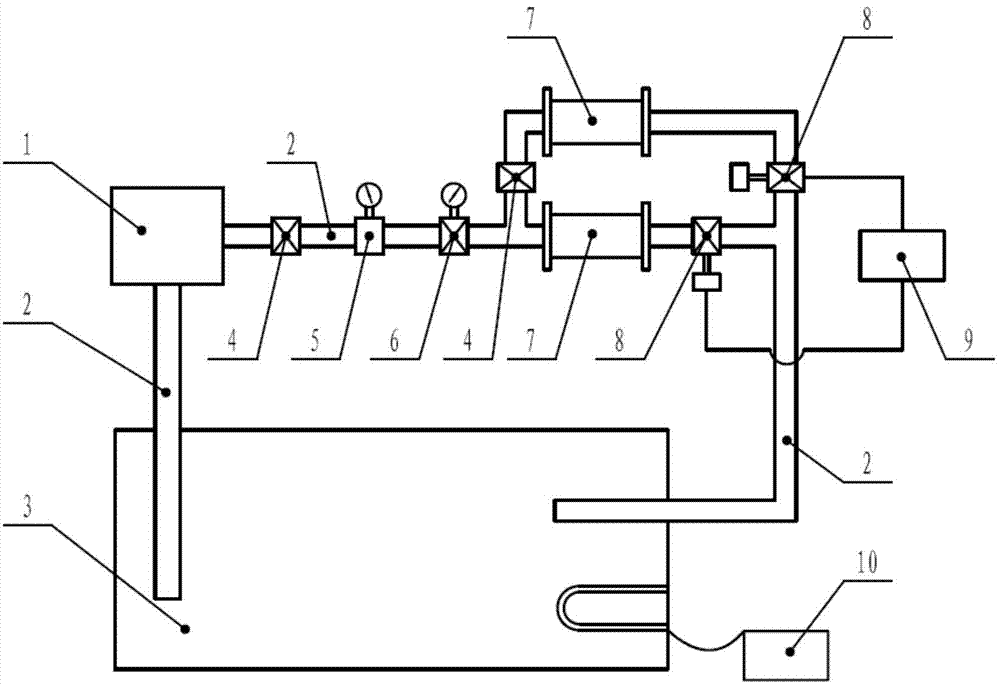

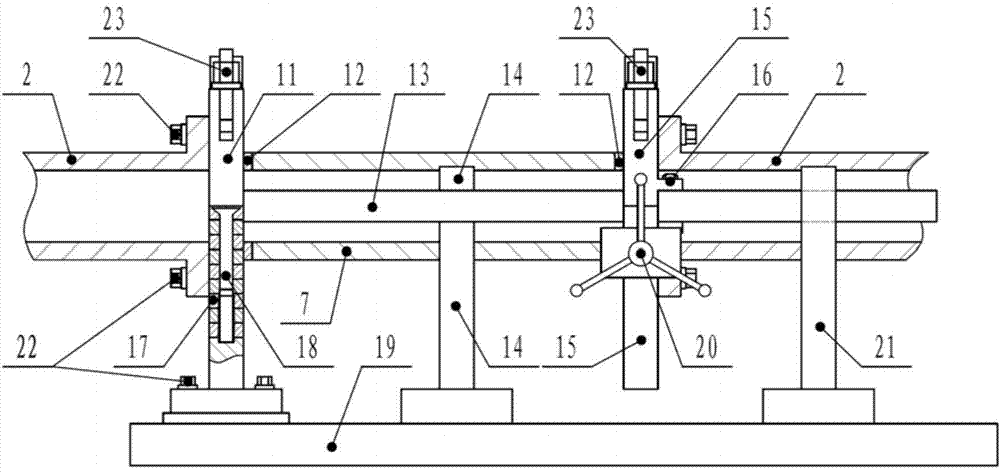

[0041] Example 1: Test the anti-sewage scaling and waxing performance of ordinary carbon steel pipes at room temperature

[0042] (1) Sample preparation: take a carbon steel pipe with a length of 200mm as the test pipe section, measure the weight of the test pipe section with an electronic balance (accuracy 0.1g), measure the inner diameter and wall thickness of the test pipe section with a vernier caliper, and conduct a survey on its inner surface morphology. Take pictures; (2) Fixture assembly: According to the test tube sample diameter, select the clamping block and assemble it in the fixed fixture and sliding fixture, and connect the PTFE delivery pipeline to the fixed fixture and sliding fixture respectively; (3) Sample assembly: put The corrosion-resistant gasket is bonded to both ends of the carbon steel pipe and placed on the sample support frame. Turn the rotating handle of the sliding fixture to make the two ends of the carbon steel pipe fit closely with the two fixtu...

Embodiment 2

[0043] Example 2: Testing the Antigen Oil Scaling and Waxing Performance of Ordinary Carbon Steel Pipes and Ceramic Lined Pipes at 40°C

[0044] (1) Sample preparation: cut carbon steel pipes and ceramic-lined pipes with a length of 300mm as test pipe sections, measure the weight of the test pipe section with an electronic balance (accuracy 0.1g), measure the inner diameter and wall thickness of the test pipe section with a vernier caliper, and compare them. Take photos of the inner surface morphology; (2) Fixture assembly: according to the caliber of the two test pipe samples, select the clamping block and assemble it in the fixed fixture and the sliding fixture, and connect the PTFE delivery pipeline to the fixed fixture and the sliding fixture respectively ; (3) Sample assembly: bond the corrosion-resistant gasket to the two ends of the carbon steel pipe and place it on the sample support frame, turn the rotating handle of the sliding fixture to make the two ends of the carb...

Embodiment 3

[0045] Example 3: Testing the anti-scaling and waxing performance of polyethylene pipes and corrosion-resistant alloy pipes at 60°C

[0046] (1) Sample preparation: Cut polyethylene pipes and corrosion-resistant alloy pipes with a length of 400mm as test pipe sections, measure the weight of the test pipe section with an electronic balance (accuracy 0.1g), measure the inner diameter and wall thickness of the test pipe section with a vernier caliper, and compare them. Take photos of the inner surface morphology; (2) Fixture assembly: according to the caliber of the two test pipe samples, select the clamping block and assemble it in the fixed fixture and the sliding fixture, and connect the PTFE delivery pipeline to the fixed fixture and the sliding fixture respectively ; (3) Sample assembly: the corrosion-resistant gaskets are bonded to the two ends of the polyethylene pipe and placed on the sample support frame, and the rotating handle of the sliding fixture is turned to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com