Hydrogen permeability testing device for metal material under high liquid pressure

A metal material, permeability technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problem of non-hydrogen permeation signal measurement and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

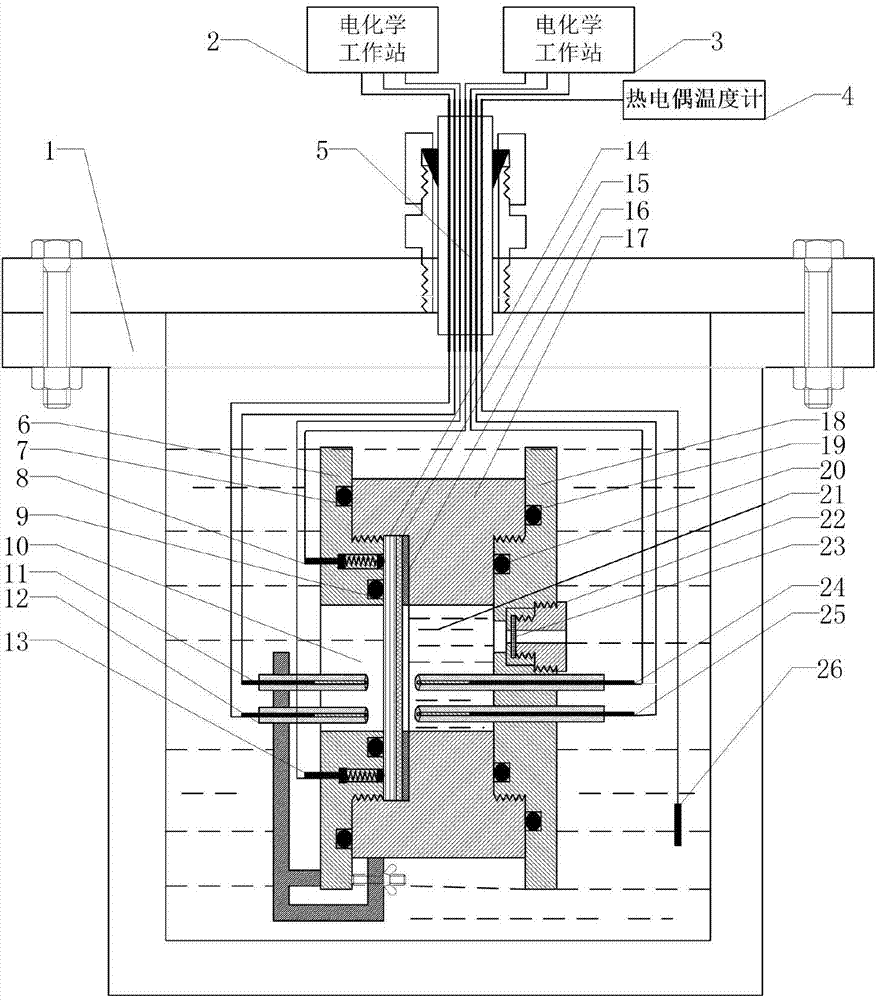

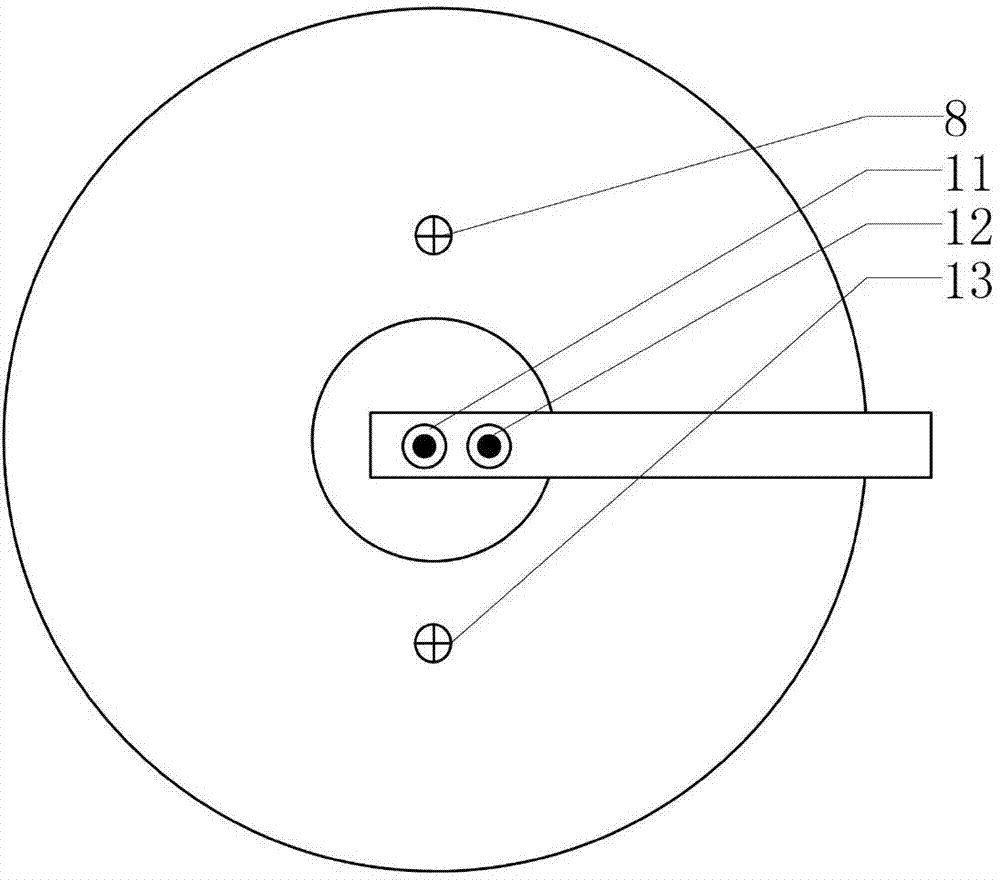

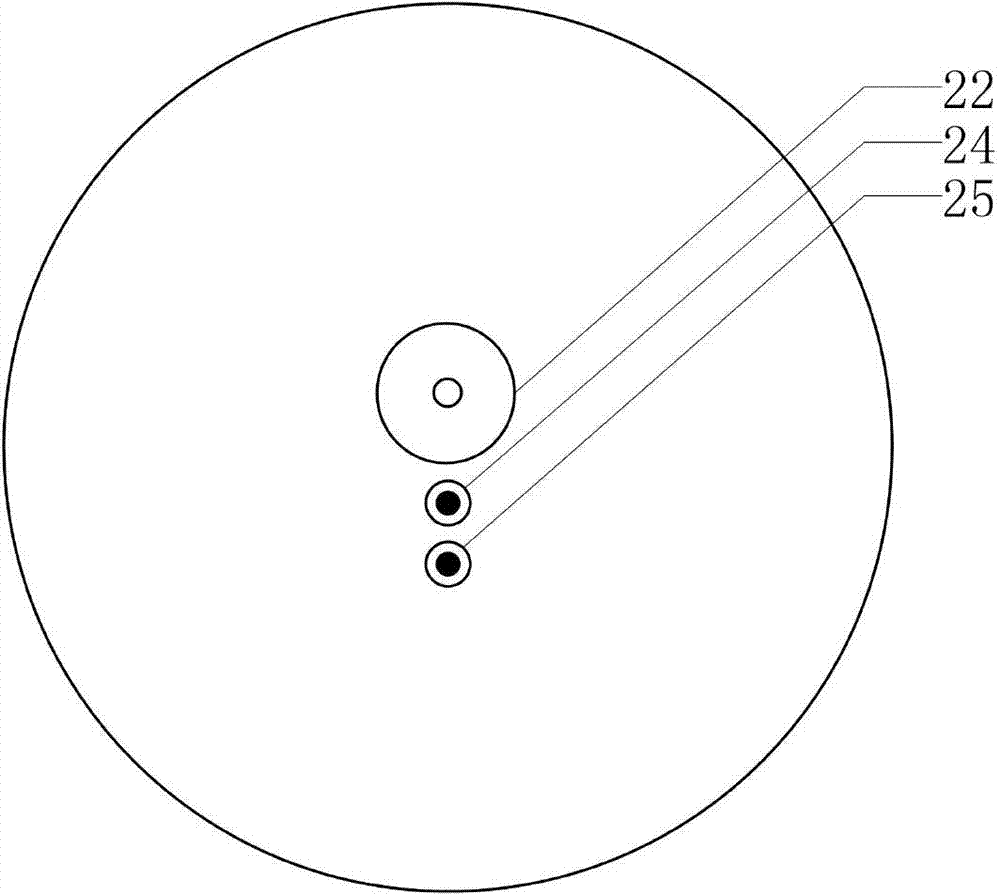

[0039] Such as figure 1 Shown is the structural diagram of the device, the bundled wire 5 protrudes from the top of the autoclave 1, and the test wires of the electrochemical workstation 1 2, electrochemical workstation 2 3 and thermocouple thermometer 4 located outside the autoclave 1 are all connected through the bundled wire 5. into the autoclave 1; the inner space formed by the bottom cover 6 of the hydrogen charging device, the middle section 17 of the hydrogen charging device and the upper cover 18 of the hydrogen charging device is the hydrogen expansion chamber 21; the O-ring-7 is located between the bottom cover 6 and the charging device Between the middle section 17 of the hydrogen device, the second O-ring 9 is located between the bottom cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com