High-density water-based drilling fluid for drilling shale

A water-based drilling fluid and drilling fluid technology, which are applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as wellbore instability, and achieve low reservoir damage, low cost, and strong high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Example 1: A preparation method for drilling shale with high-density water-based drilling fluid.

[0014] First measure 1000 grams of tap water and raise the water temperature to 65°C, add 30 grams of bentonite for drilling fluid under electric stirring at a low speed of 600r / min, stir for 10 minutes and add 2 grams of Na 2 CO 3 Stir for another 30 minutes. After prehydration for 24 hours at normal temperature and pressure, add 1 gram of drilling fluid under electric stirring at a low speed of 500 r / min. Stir carboxymethyl starch GMS-1 for 5 minutes, add 10 grams of high temperature resistant special resin SPNH-Ⅲ and stir for 5 minutes, add 15 grams of high temperature resistant viscosity reducer JNT-1 and stir for 15 minutes, add 30 grams of lubricating nanoemulsion NL-Ⅲ and stir After 15 minutes, add 10 grams of non-fluorescent white asphalt anti-slump agent WBF-II and stir for 5 minutes; add 30 grams of water-dispersed cationic emulsified asphalt powder SFT-I and st...

example 2

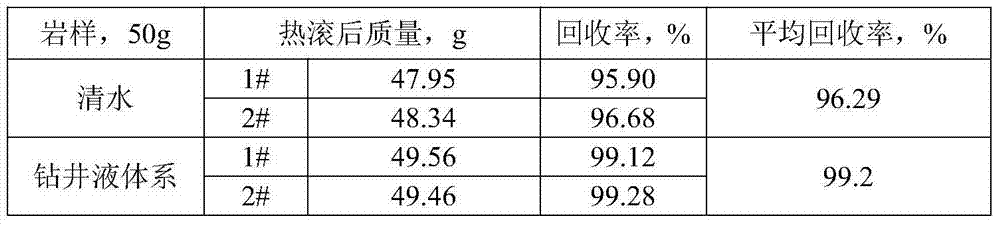

[0015] Example 2: The rolling recovery rate of the high-density water-based drilling fluid system of the present invention was measured using an XGRL-2 type roller heating furnace.

[0016] Table 2 Rolling recovery rate of rock samples (150℃ / 16h)

[0017]

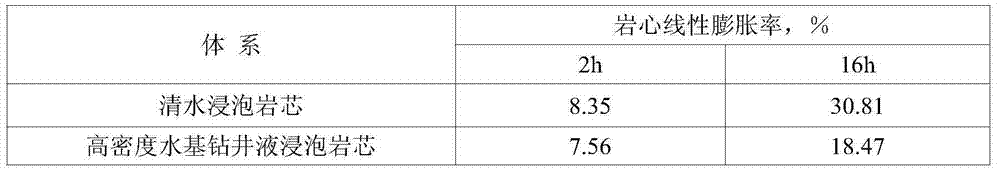

[0018] Table 3 Experimental results of linear expansion of this high-density water-based drilling fluid system

[0019]

[0020] From Table 2 and Table 3, the rolling recovery rate and linear expansion rate experiments of this high-density water-based drilling fluid show that the rolling recovery rate is over 99%, and the 16h linear expansion rate is only 18.47%, which shows that the water-based drilling fluid system has a good suppression performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com