Wire-arranging mechanism of intermediate drawing take-up machine

A wire take-up and wire arrangement technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, can solve the problems of high cost, difficult adjustment, complex structure, etc., and achieves low cost and convenient adjustment. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

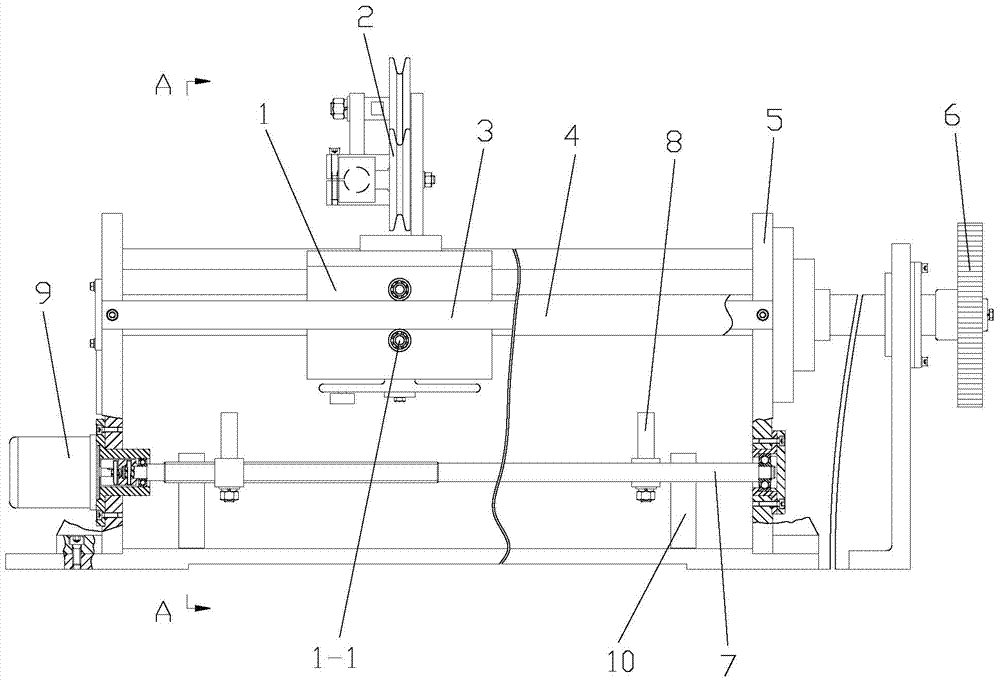

[0021] Such as Figure 1 to Figure 3 As shown, the present invention includes a support 5, a screw 7, a bumper 8 and a light rod cable arrangement 1, the two ends of the screw 7 are respectively connected to the left and right sides of the bottom of the support 5, and the screw 7 The quantity is two and two screw mandrels 7 are arranged parallel to the front and rear, one end of the said screw mandrel 7 is provided with a synchronous motor 9 for driving its rotation, the left end of the screw mandrel 7 positioned at the front side is provided with a screw thread, and the screw mandrel 7 at the rear side is provided with a screw thread. The right end of the rod 7 is provided with threads, and the number of the touch rods 8 is two and the two touch rods 8 are arranged parallel to each other. The left end of the screw rod 7 on the rear side is slidably connected, the rear end of the bumper 8 on the right is threadedly connected to the right end of the screw rod 7 on the rear side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com