Pneumatic flour transmitting system

A conveying system and negative pressure pneumatic conveying technology, which is applied in the field of pneumatic conveying system and flour pneumatic conveying system, can solve the problems such as the large influence of mixing effect, and achieve the effect of low operating cost, simple conveying system and large conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

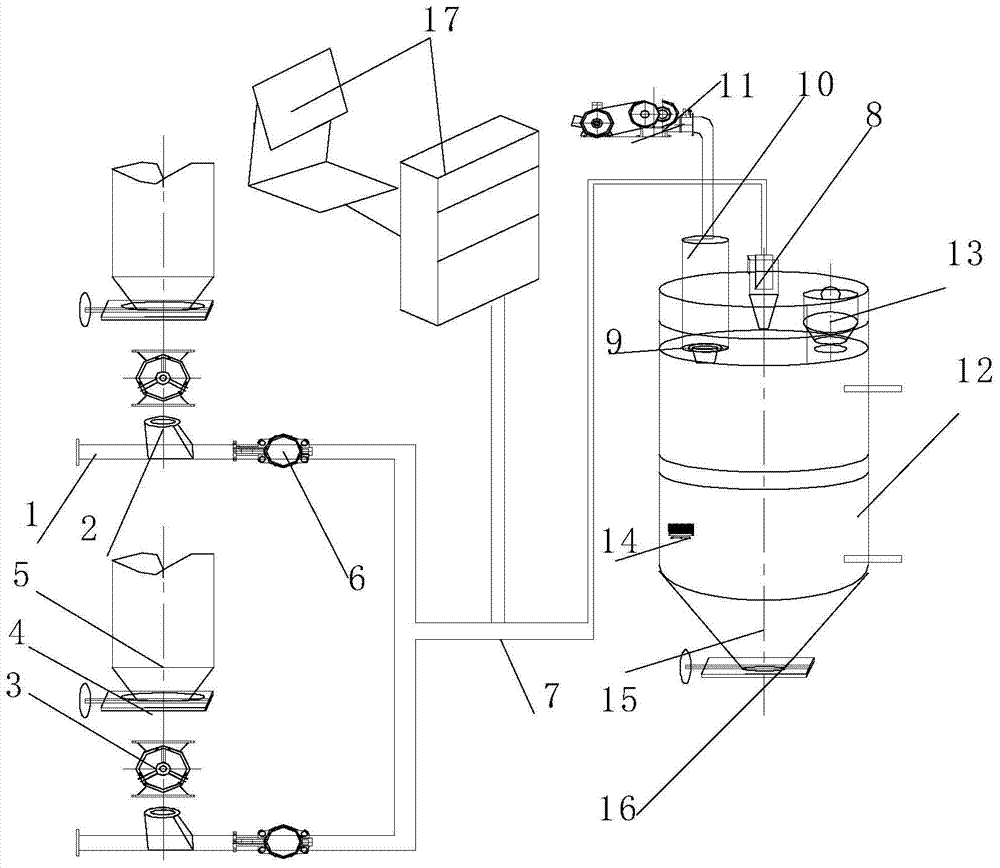

[0009] Embodiment 1 Composition and function of a pneumatic conveying system for flour:

[0010] The conveying system includes flour and air flow pipeline Ⅰ1, gas-solid mixing acceleration chamber 2, electric discharge valve 3, electric flapper valve 4, hopper 5, pneumatic reversing valve 6, flour and air flow pipeline Ⅱ7, cyclone dust collector 8, closing Fan 9, pulse back blowing bag filter 10, Roots blower 11, silo 12, pressure release valve 13, vibrating air hammer 14, activation hopper 15, pneumatic flapper valve 16, electrical control system 17, characterized in Roots blower 10 uses negative pressure to suck and convey dilute phase flour. It is suitable for conveying systems with short distance, large conveying capacity and continuous conveying requirements. It is a flour pneumatic conveying system that can convey flour from multiple points to one point. The gas-solid mixing chamber 2 is used for mixing flour and air flow, so that the flour has acceleration. The elect...

Embodiment 2

[0011] Embodiment 2 The working process of a pneumatic conveying system for flour:

[0012] After the flour is added from the hopper 5, it enters the gas-solid mixing acceleration chamber 2 through the electric discharge valve 3. At this time, the branch flour and one end of the air flow pipe I are open to the atmosphere, and the air flow is sucked into the pipe under the action of the Roots blower 11. , mixed with flour in the gas-solid mixing acceleration chamber 2, controlled by the pneumatic switching valve 6 according to the process and production needs, entering the flour and air flow pipeline II 7, entering the cyclone dust collector 8 and feeding into the silo 12, and passing through the pneumatic inserting plate The outlet of valve 16 is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com