Automatic bottle removing mechanism of plastics hollow container stretching-blowing device

An empty container and stretch-blow machine technology, applied in the field of plastic machinery, can solve problems such as troublesome debugging, many wearing parts, and difficult maintenance, and achieve the effects of ensuring product quality, long service life and low maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

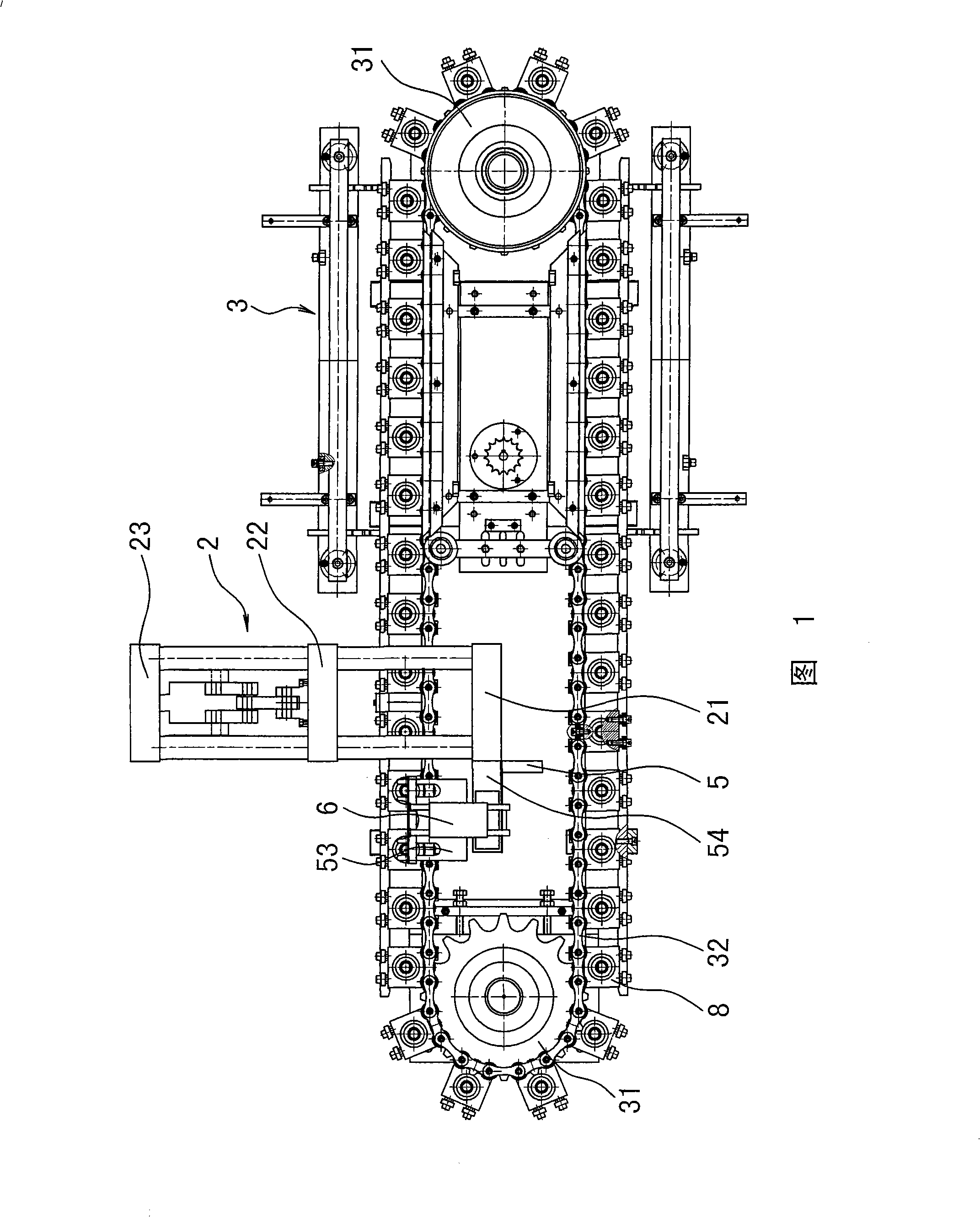

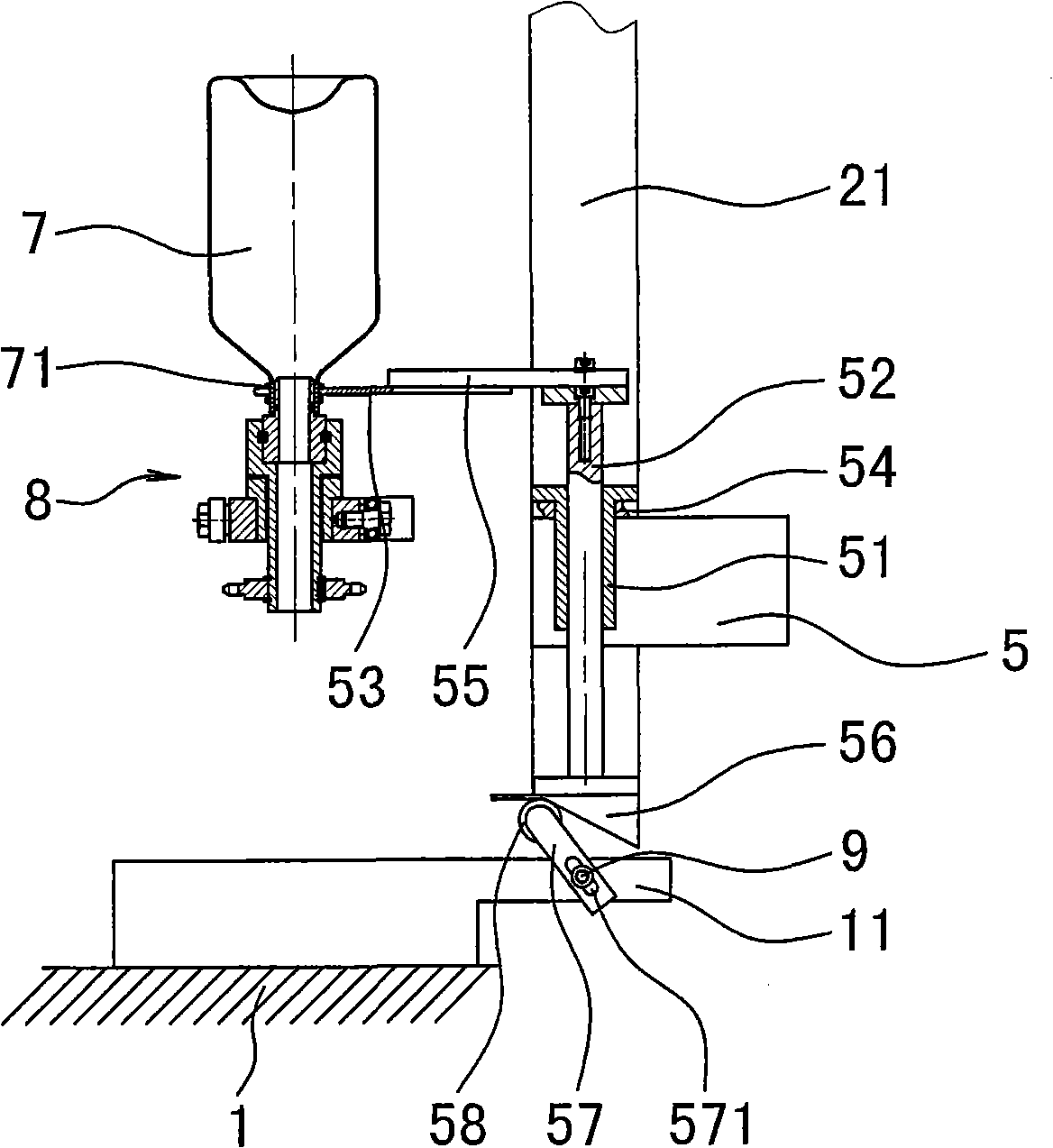

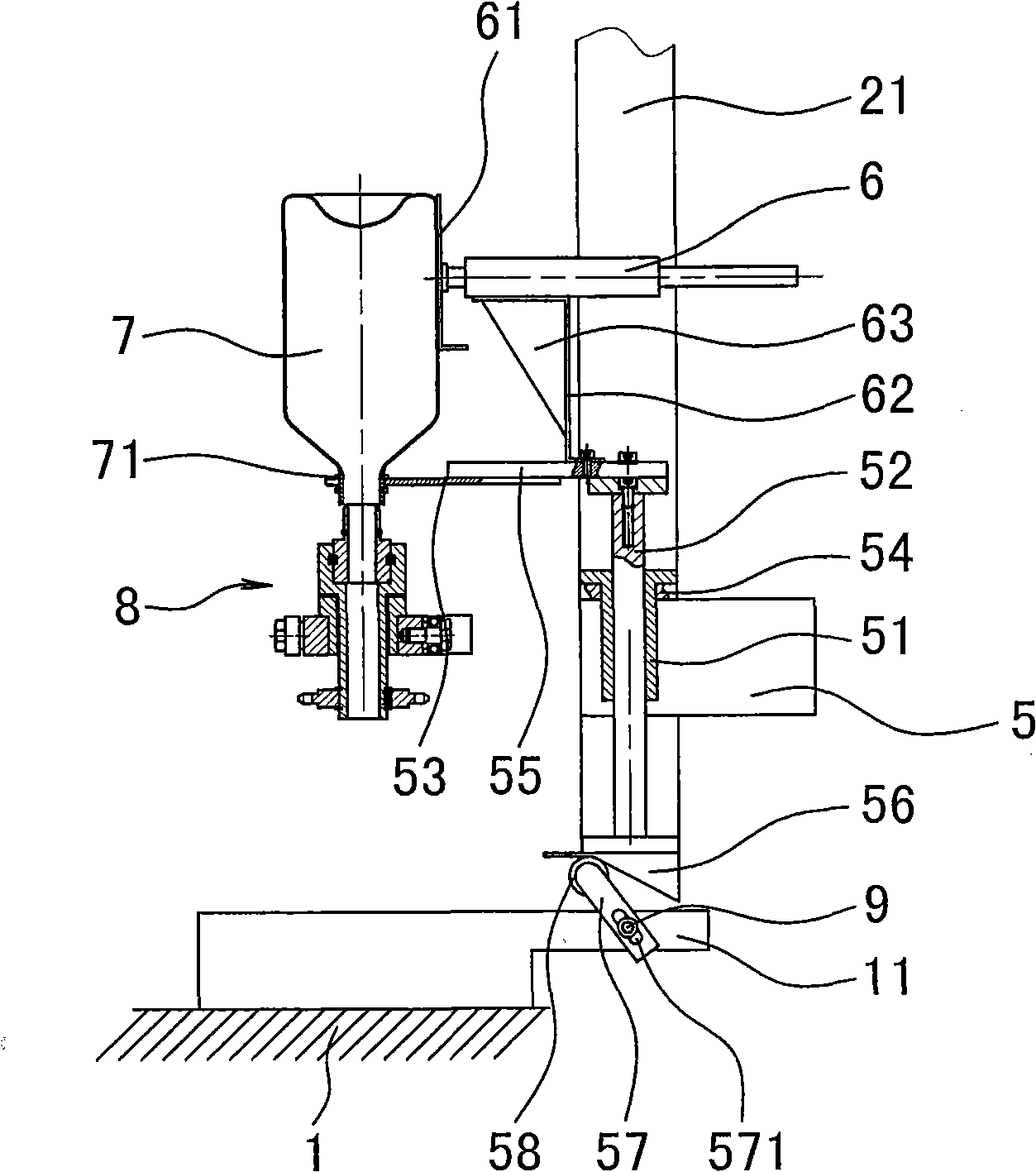

[0012] The invention discloses an automatic bottle-removing mechanism of a plastic hollow container forming stretch-blow machine, as shown in Fig. The system includes a front template 21, a middle template 22 and a rear template 23, a mold opening and closing mechanism that drives the template movement, and a stretching and blowing mechanism. The bottle tube heating system includes a sprocket 31, a chain 32 and a power delivery mechanism, and The heating device composed of the bracket and the lamp tube is characterized in that a fixed plate 5 is installed on the side of the front template 21, the fixed plate is connected with a support plate 54, a linear guide rail 51 is installed in the support plate, and there are up and down moving guide rods 52 in the linear guide rail. The bottom of 52 is in contact with the lifting top block or the cam on the frame, and the bottle-removing fork 53 is installed on the top of the guide rod, and the mouth of the bottle-removing fork 53 coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com