High frequency sewing machine

A sewing machine and high-frequency technology, which is applied in the field of high-frequency sewing machines, can solve the problems of poor quality of finished clothing products, scorched or scalded fiber fabrics, and wrinkled fiber fabrics, etc., to achieve a good visual effect and appearance, and to prevent scorching , to avoid wrinkling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below with reference to the drawings.

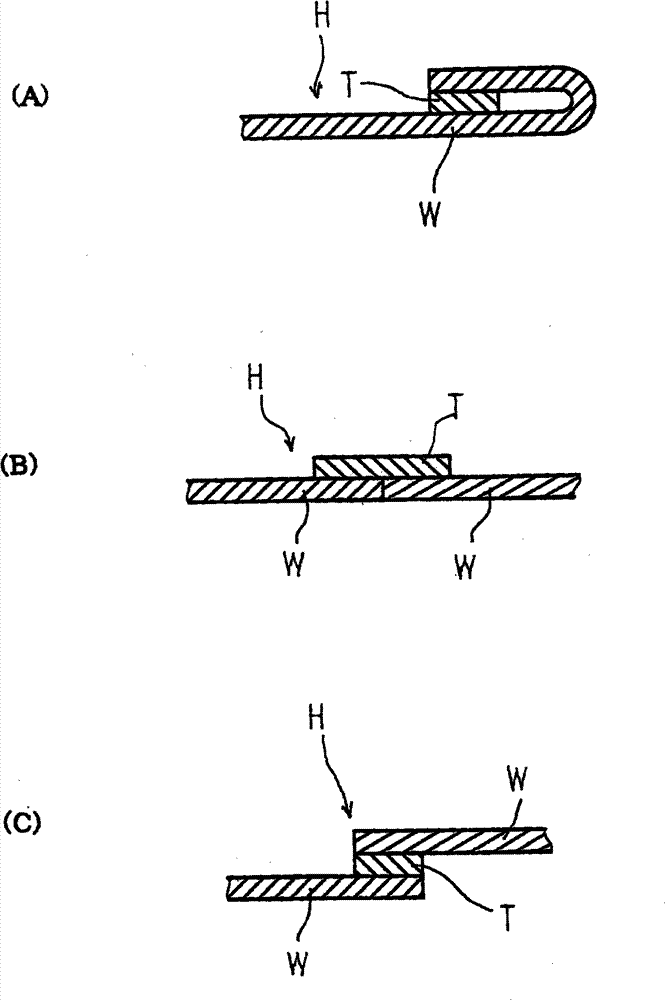

[0055] figure 1 It is a perspective view of the overall appearance of the high-frequency sewing machine according to the embodiment of the present invention, figure 2 It is a left side view showing a part of the whole high-frequency sewing machine, image 3 It is an enlarged cross-sectional view of the main part of the processed material as the processing object of this high-frequency sewing machine, Figure 4 An enlarged longitudinal sectional front view of main parts for explaining the main part structure of the high-frequency sewing machine, Figure 5 It is an enlarged longitudinal sectional side view of main parts for explaining the structure of main parts of this high-frequency sewing machine.

[0056] Such as figure 1 and figure 2 As shown, a high-frequency sewing machine 1 is composed of a sewing machine main body 2 , a sewing machine arm 3 and a sewing machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com