Reducing production method of deepwater submerged arc welding large-caliber steel pipes

A manufacturing method, submerged arc welding technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of reduced compressive strength and failure to meet the crushing pressure performance requirements of pipelines used in deep water, so as to reduce residual stress, The effect of optimizing the cold forming process and reducing the pipe diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

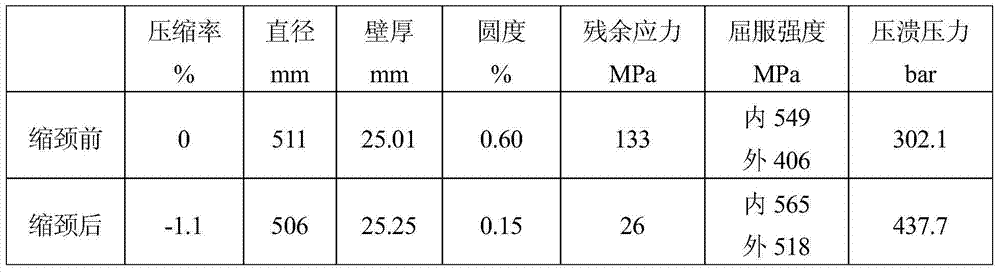

[0047] The X65 controlled-rolled steel plate with a width of 1525 mm and a thickness of 25.4 mm was used to manufacture φ508 straight seam submerged arc welded steel pipes. Proceed as follows:

[0048] 1) Edge milling and groove processing: The two edges of the steel plate are milled on both sides by the edge milling machine to achieve the required plate width, plate edge parallelism and groove shape.

[0049] 2) Pre-bending: According to the design and technical requirements of the steel pipe, use the pre-bending machine to bend the edge of the plate to the required curvature.

[0050] 3) JCO forming:

[0051] First, use the JCO forming machine to punch half of the pre-bent steel plate multiple times to form a "J" shape;

[0052] Then press the other half of it for the same number of times to form a "C" shape;

[0053] Finally, press once in the middle of the entire steel plate to form an open "O" shape.

[0054] 4) Jointing and pre-welding: By adjusting the position of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com