Multi-energy level spark detection system with locking function

A spark detection, multi-level technology, applied in the field of electronics, can solve problems such as power modules and power tubes easily damaged, and achieve the effect of reducing secondary dust, strong anti-interference ability, easy debugging and equipment upgrades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

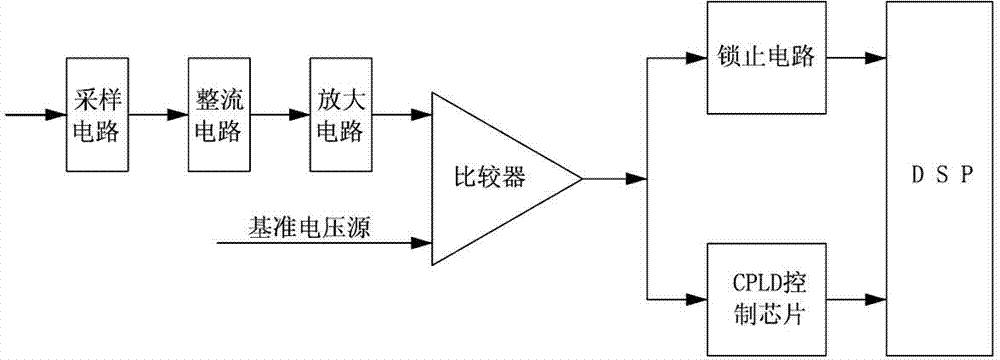

[0030] Such as figure 1 Shown is the schematic block diagram of the circuit of the present invention, a multi-level spark detection system with locking function, including a sampling circuit, a conditioning circuit, a comparator D1, a spark energy level discrimination circuit and a locking circuit, and the locking circuit is used for breaking Open the output terminal of the high voltage power supply.

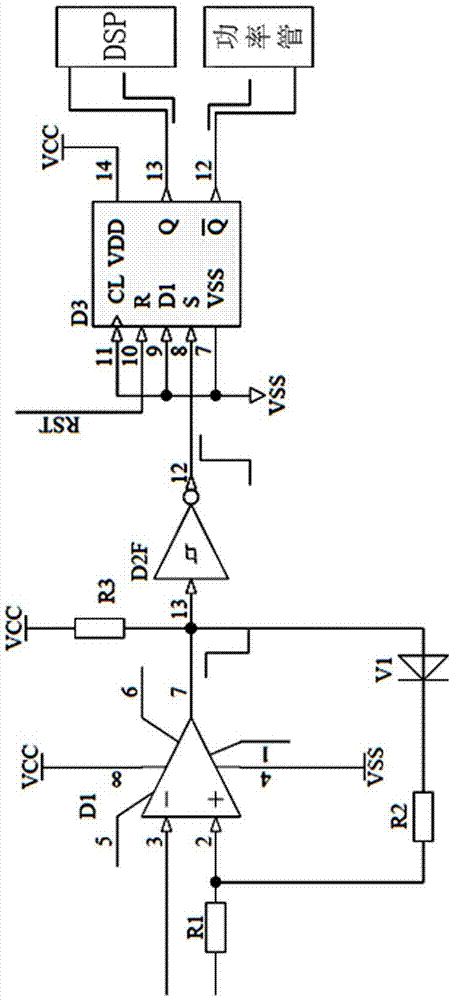

[0031] The sampling circuit is composed of a Hall sensor and a power resistor. The Hall sensor collects the current signal output by the inverter module of the high-voltage power supply. The sampling signal is a weak current signal of 0-100mA, which is converted into an AC voltage signal by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com