Crystal silicon and silicon carbide film compound unijunction PIN solar battery with transition layer, and preparation method thereof

A solar cell and transition layer technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that no one has developed a single-junction PIN solar cell manufacturing method, and no one has developed a thin-film solar cell manufacturing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

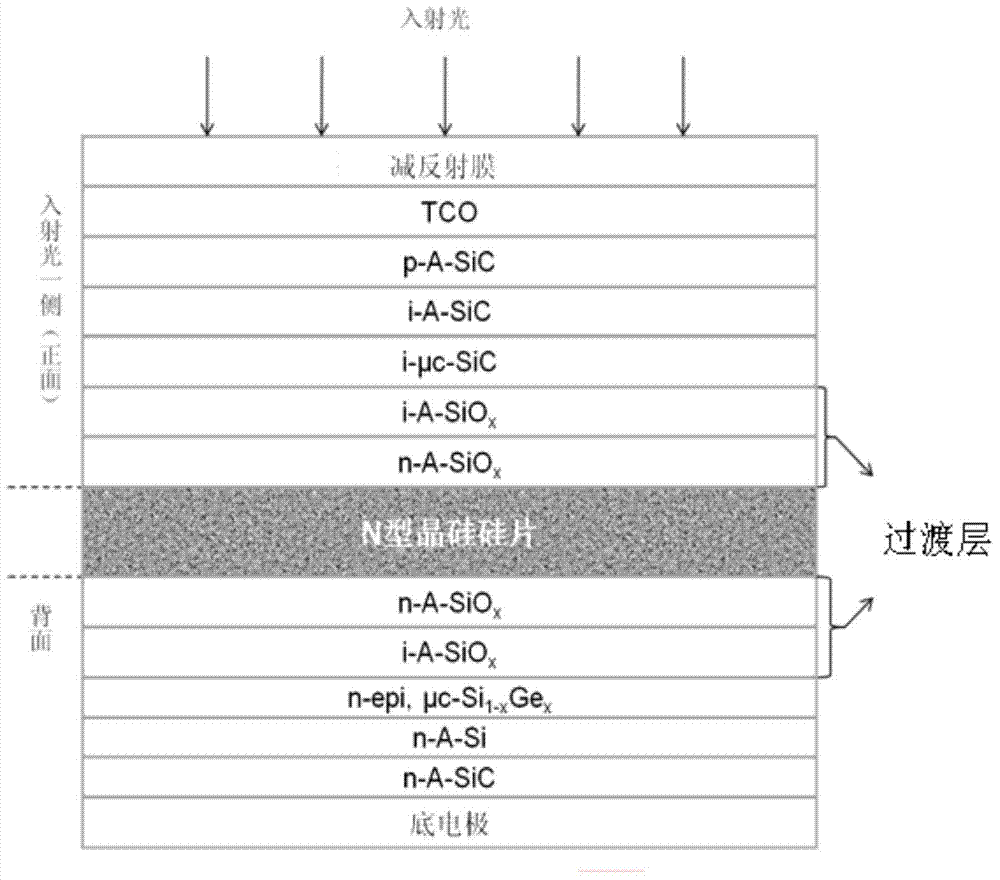

[0077] Crystalline silicon and silicon carbide film composite single-junction PIN solar cells with a transition layer structure, selected from one of the following solar cell structures:

[0078] 1) Bottom electrode / n layer / n-type silicon wafer / transition layer / i-A-SiC layer / p-A-SiC layer / TCO / anti-reflection film;

[0079] 2) Bottom electrode / n layer / n-type silicon wafer / transition layer / i-μc-SiC layer / i-A-SiC layer / p-A-SiC layer / TCO / anti-reflection film;

[0080] 3) Bottom electrode / n layer / n-type silicon wafer / transition layer / p-A-SiC layer / TCO / anti-reflection film;

[0081] 4) Bottom electrode / n layer / transition layer / n-type silicon wafer / i-A-SiC layer / p-A-SiC layer / TCO / anti-reflection film;

[0082] 5) Bottom electrode / n layer / transition layer / n-type silicon wafer / i-μc-SiC layer / i-A-SiC layer / p-A-SiC layer / TCO / anti-reflection film;

[0083] 6) Bottom electrode / n layer / transition layer / n-type silicon wafer / p-A-SiC layer / TCO / anti-reflection film;

[0084] 7) Bottom electr...

Embodiment 2

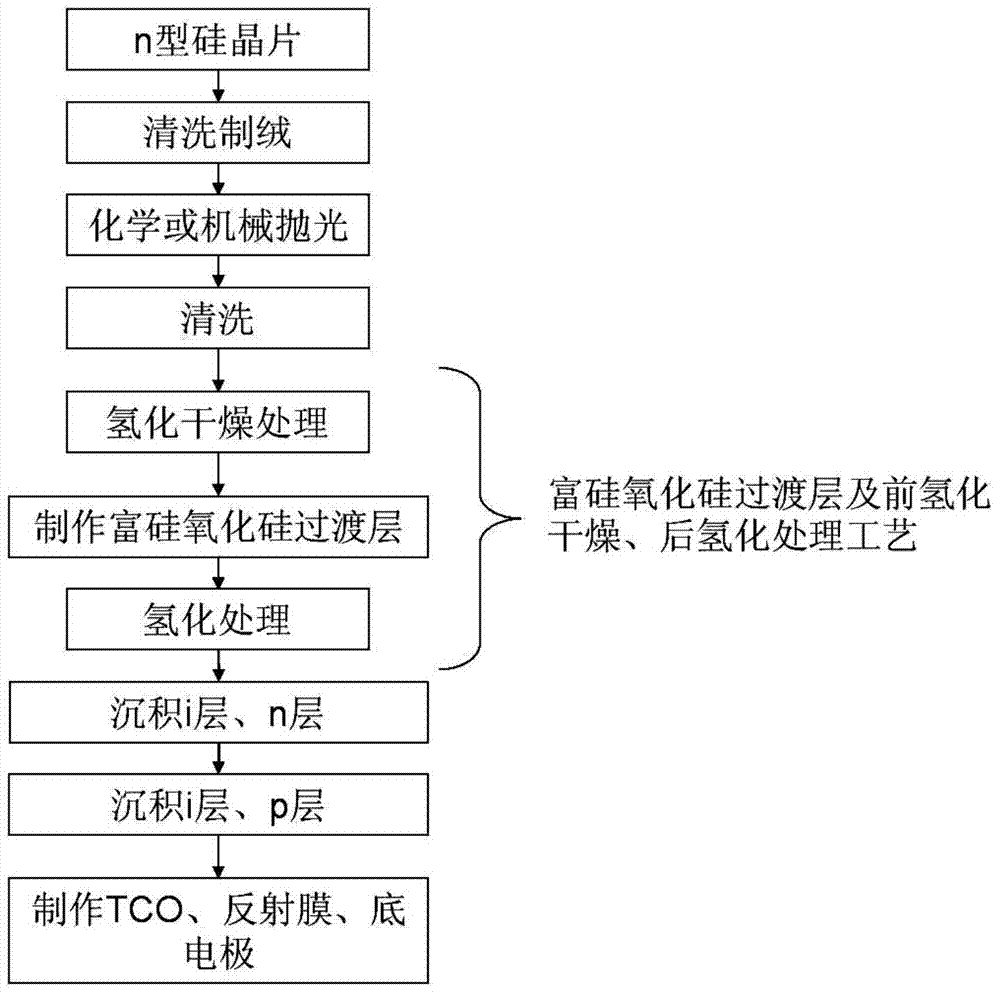

[0093] The manufacturing method of the transition layer, such as figure 2 shown, including the following methods:

[0094]The first type: After preliminary cleaning, chemical texturing, chemical or mechanical double-sided polishing of the n-type silicon wafer, the n-type silicon wafer is cleaned again, and the cleaned silicon wafer is pre-hydrogenated and dried. The treatment method is as follows: : Send the silicon wafer to the equipment with a closed chamber, evacuate the atmosphere until the chamber pressure is less than or equal to (≤) 1Pascal; the chamber temperature is controlled between 30°C and 350°C, and hydrogen or a mixture of hydrogen and nitrogen is introduced gas; dry silicon wafers under a hydrogen atmosphere. The purity of hydrogen and nitrogen is greater than or equal to (≥) 99.99%; if a mixed gas is used, the volume ratio of hydrogen and nitrogen is 0.1 to 100 times; the hydrogenation drying time is 1 to 60 minutes. Send the hydrogenated and dried silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com