Super large diameter sonic nozzle group type gas flowmeter verification device

A gas flow meter and sonic nozzle technology, which is applied in the field of gas flow meter verification device of super large diameter sonic nozzle group, can solve the problems of very large influence, waste of energy consumption, uneven temperature distribution, etc., so as to reduce the space occupied and installation. structure, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

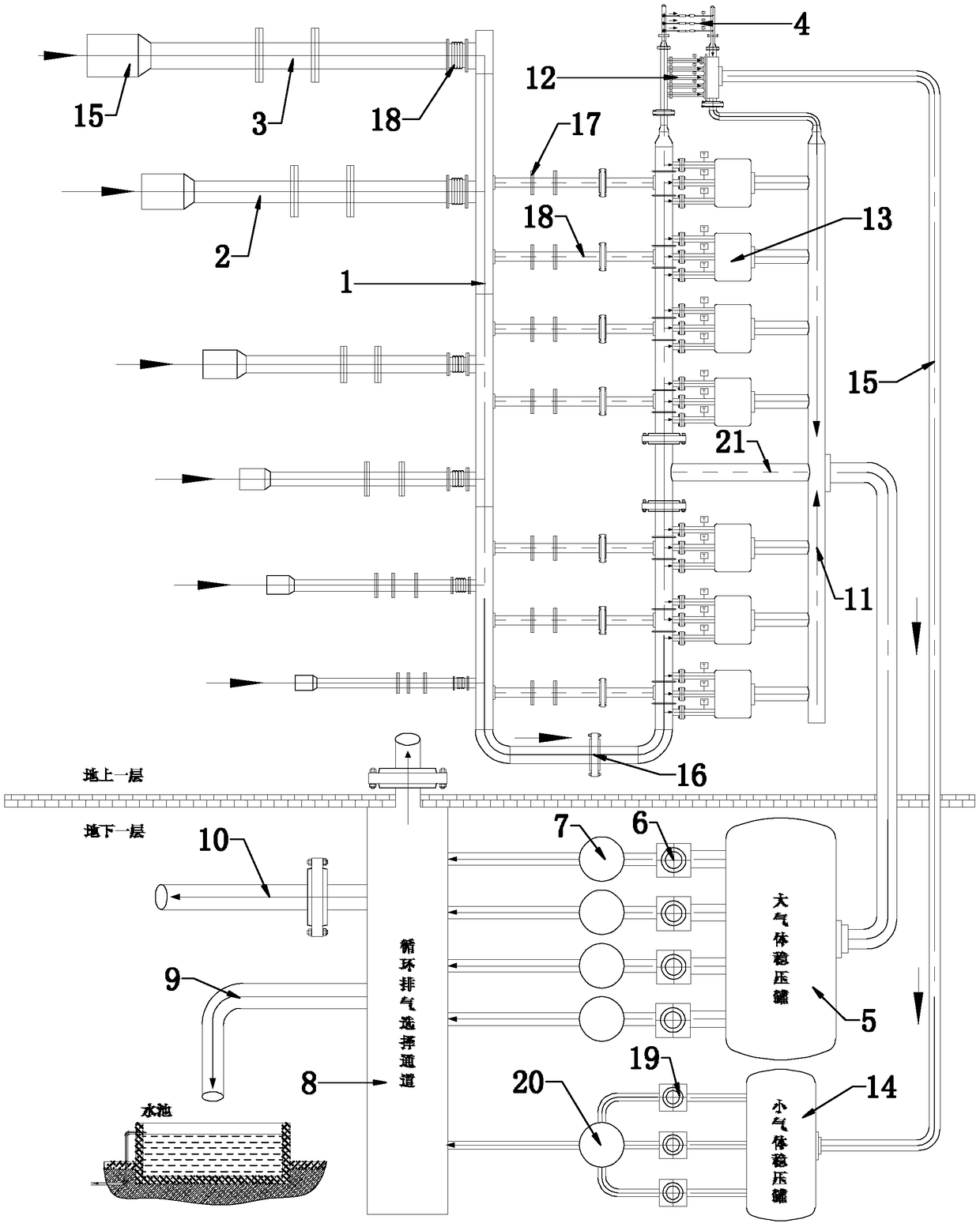

[0019] The ultra-large-diameter sonic nozzle group-type gas flowmeter verification device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in the figure, the ultra-large caliber sonic nozzle group type gas flow meter verification device of the present invention includes a gas flow verification part located on the ground and a gas discharge part located underground; the gas flow verification part includes a U-shaped manifold 1, a U-shaped manifold The pipe 1 has two parallel sections and a connecting section connected between the parallel sections. The U-shaped manifold 1 is divided into two sections by the middle part of the connecting section. The U-shaped manifold in the front section is connected with multiple detection devices with different calibers. Pipeline 2, each detection pipeline 2 is equipped with a clamping station 3, the clamping station 3 is used to install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com