Sliding type piezoelectric valve used for discharging particle-contained liquid

A sliding, piezoelectric valve technology, applied in valve details, valve devices, engine components, etc., to achieve the effect of less adjustment parameters, accurate control, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

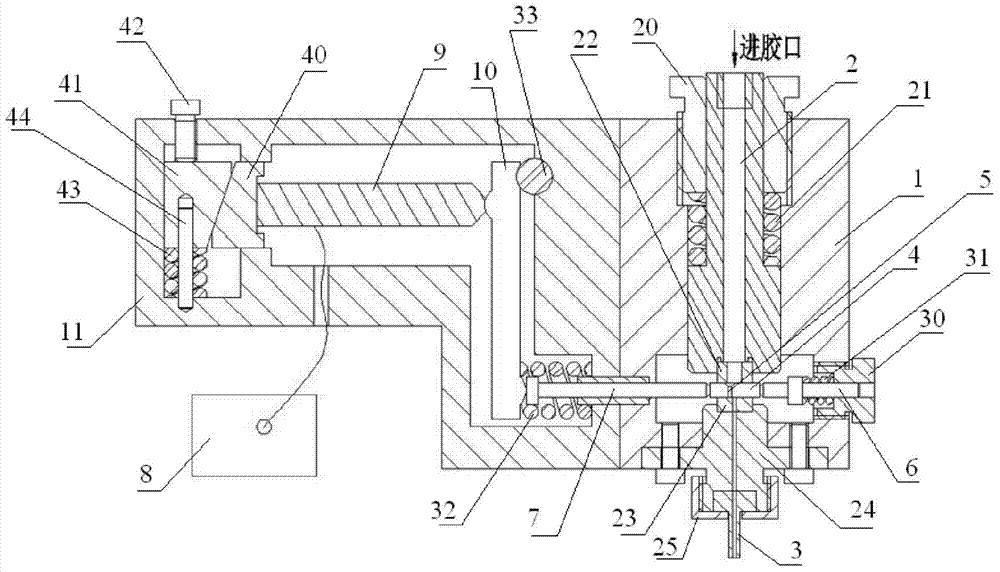

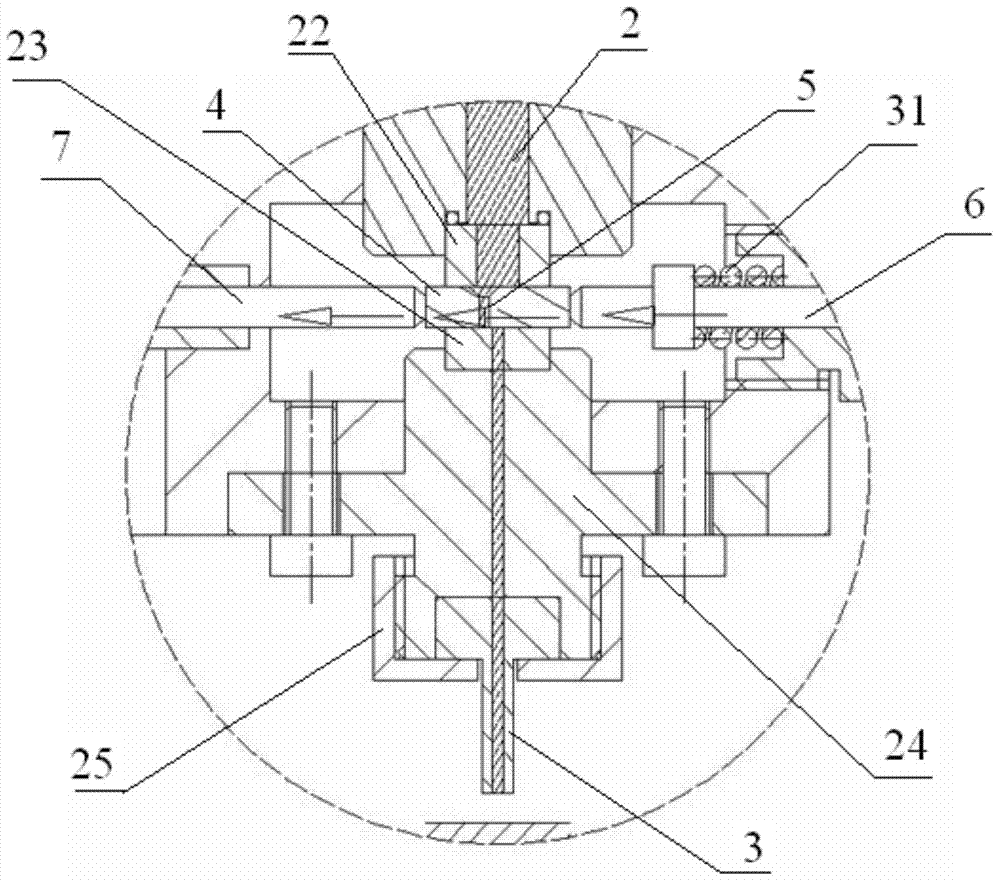

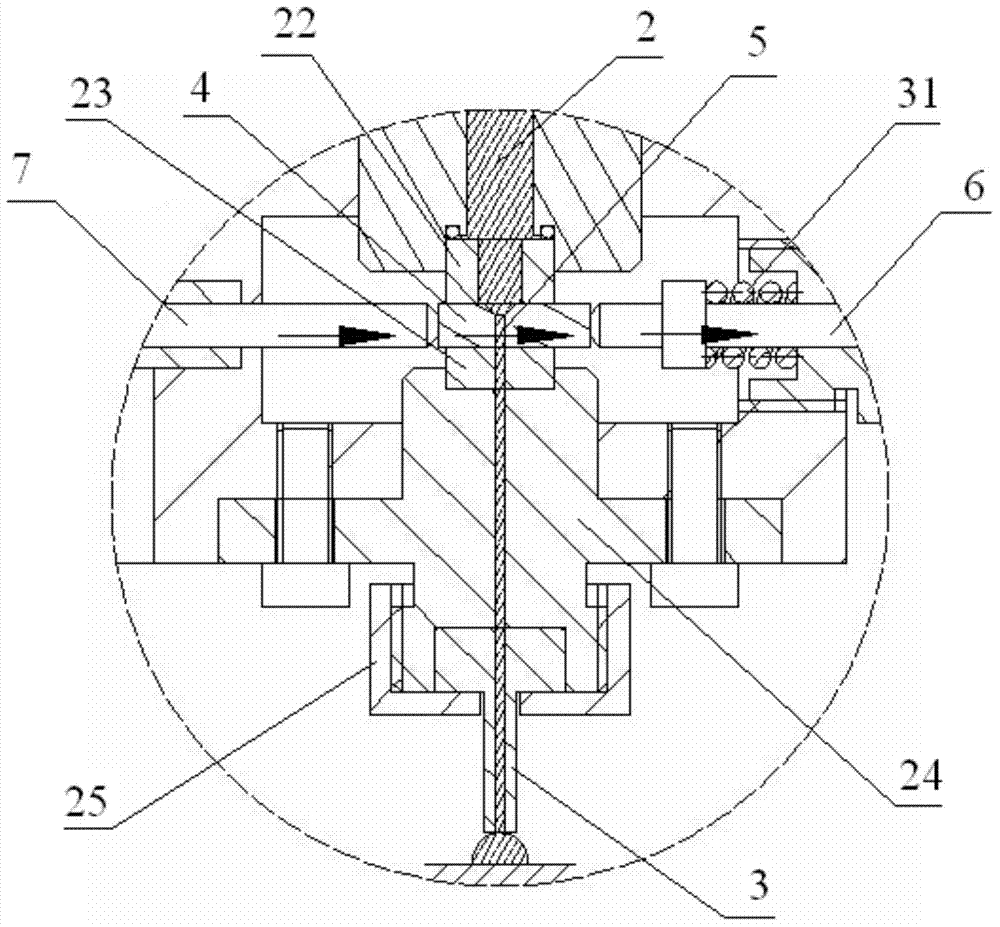

[0029] see figure 1 , figure 2 and image 3 Shown:

[0030] The sliding piezoelectric valve for discharging liquid containing particles provided by the present invention includes a valve system and a power system, wherein the valve body 1 of the valve system is provided with a liquid inlet pipe 2, and the lower end of the liquid inlet pipe 2 is provided with a needle 3, The liquid outlet of the inner cavity of the liquid inlet pipeline 2 is set correspondingly to the liquid inlet of the needle 3 infusion tube, and a slider 4 is arranged between the inner cavity liquid outlet of the liquid inlet pipeline 2 and the liquid inlet of the needle 3 infusion tube. The block 4 is provided with a pipeline 5, and the pipeline 5 on the slider 4 can correspond to the liquid outlet of the inner cavity of the liquid inlet pipeline 2 and the liquid inlet of the needle 3 infusion tube. The right end of the slider 4 is provided with a first Push rod 6, the left end of slide block 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com