A prestressed full-length anchor bolt support method

A full-length anchoring and bolting technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of difficult construction, complex construction technology, and large holes, with less impact on the arrival time and increased Resistance to deformation, ease of developmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

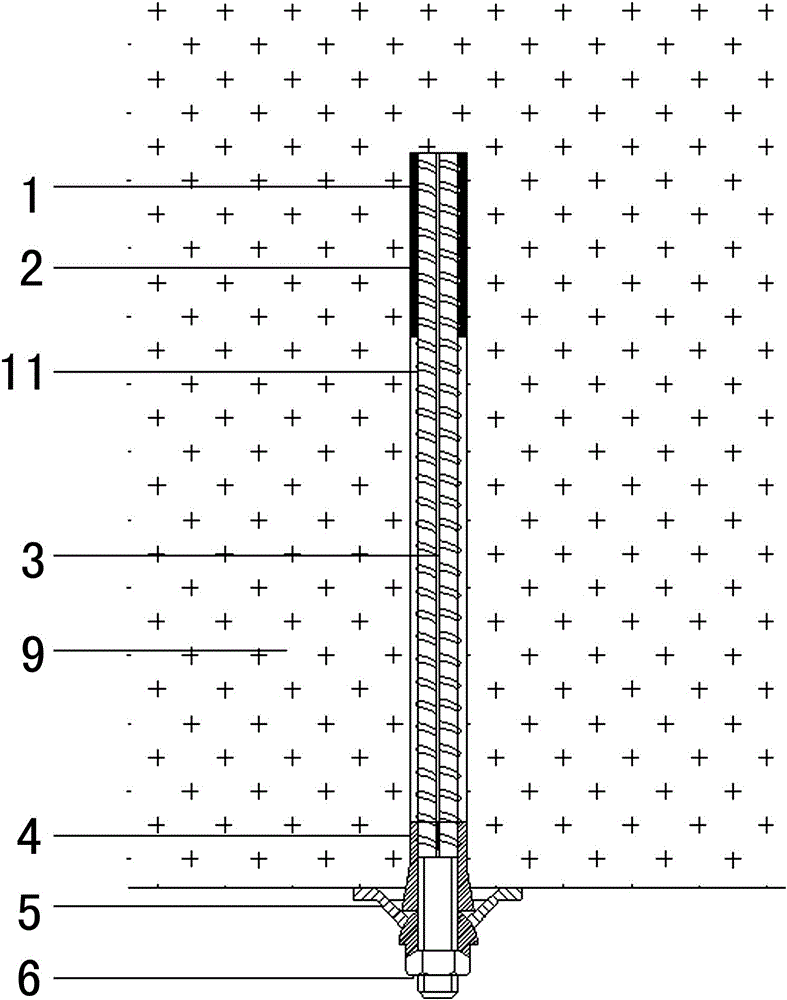

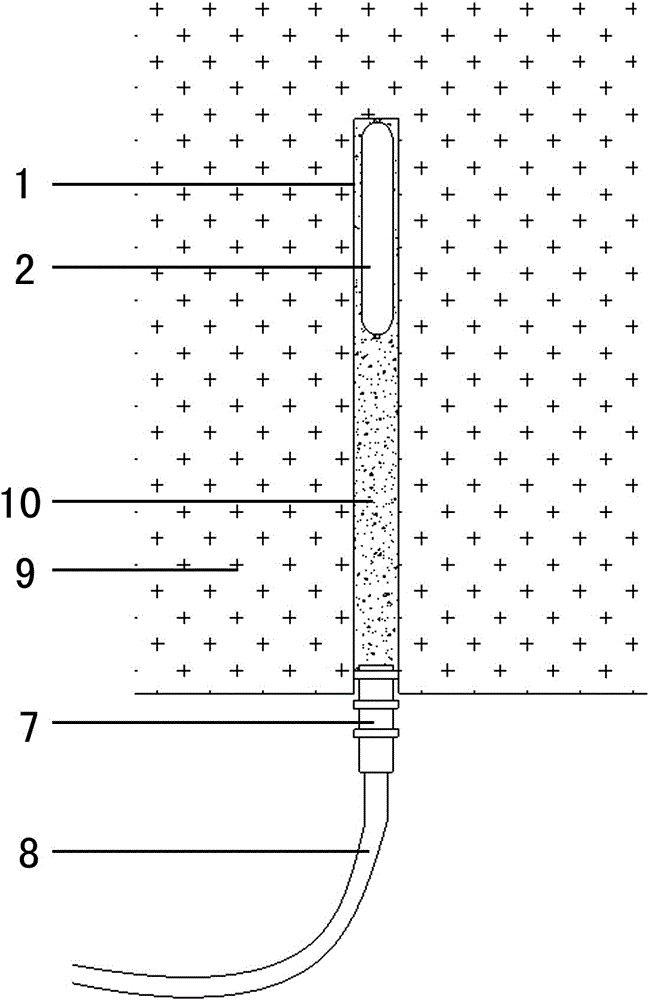

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] refer to Figure 1-2 , a kind of prestressed full-length anchor bolt support method described in this specific embodiment, comprises the following steps:

[0030] a. Drill a small hole 1 on the top of the roadway with a pneumatic rock bolter, and clean the hole after drilling the small hole 1;

[0031] b. Take the resin drug roll 2 and place it at the opening of the small hole 1, connect the top of the grouting pipe 8 to the hole sealer 7, and push the resin drug roll 2 at the end of the hole sealer 7, so that the resin drug roll 2 is installed in the small hole 1 bottom;

[0032] c. Connect the grouting pipe 8 to the grouting pump, turn on the grouting pump, inject grout into the grouting pipe 8, inject the cement slurry 10 into the small hole 1 through the grouting pipe 8, and surround the resin medicine volume 2 with the cement slurry 10 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com