Laser drill, laser drilling tool and well drilling rock breaking method

A technology of laser head and drill bit, which is applied in the fields of laser drilling tools and drilling and breaking rocks. It can solve the problems of low drilling efficiency and inability to observe in real time in hard rock strata, and achieve the effects of preventing blowout, reducing loss and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

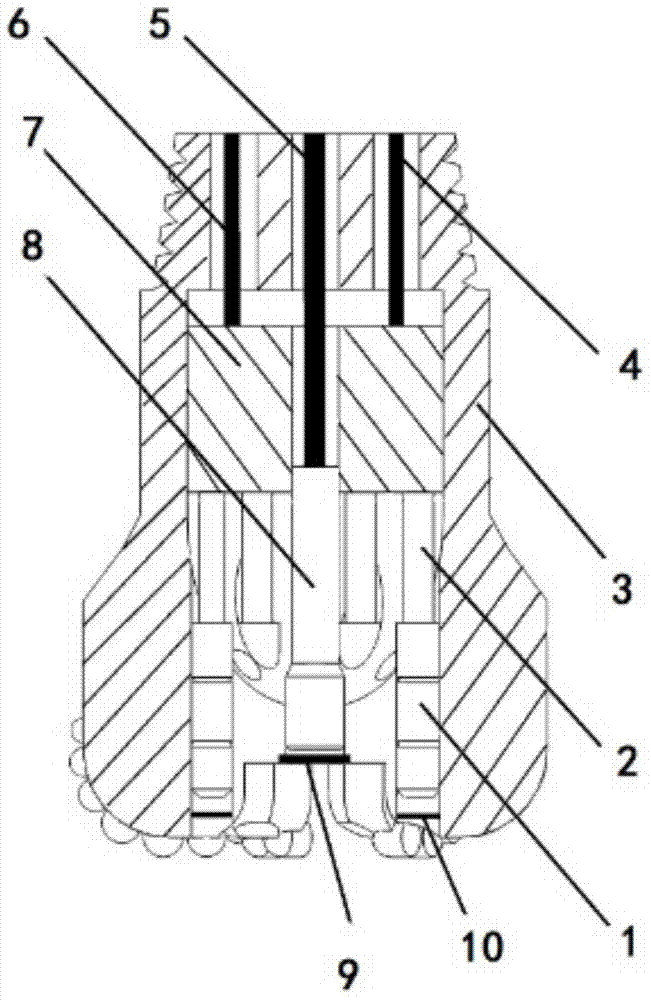

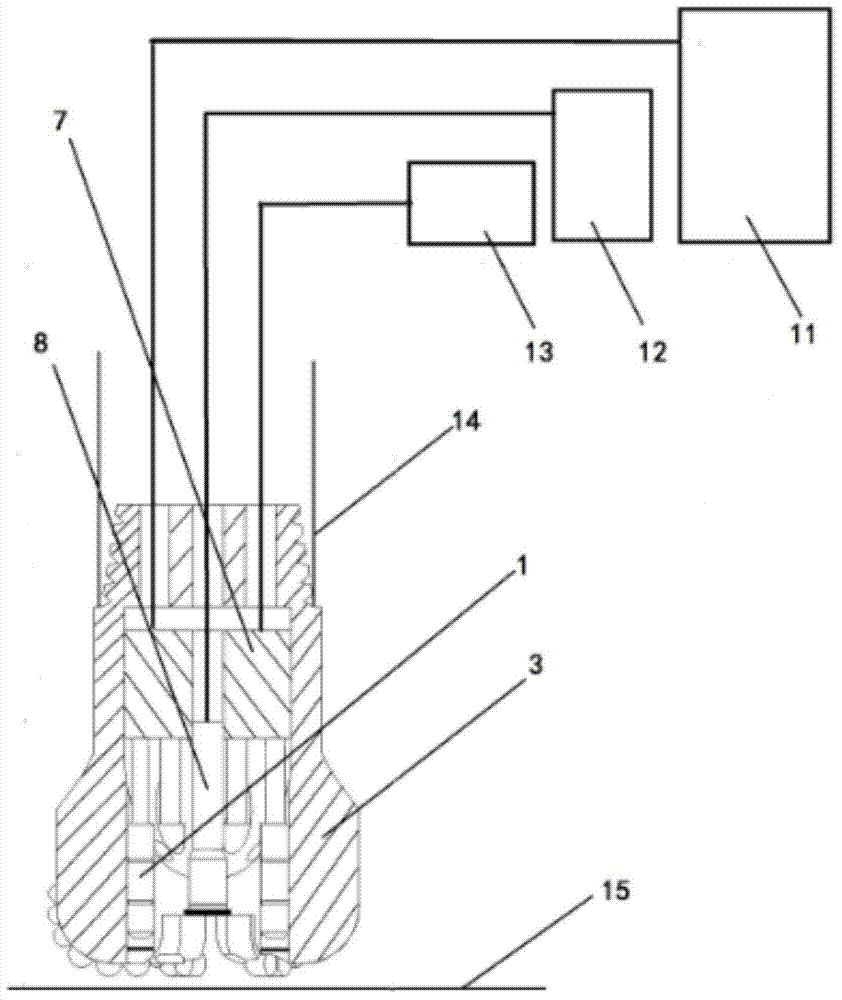

[0031] A kind of laser drill, comprises drill body 3, contains camera 8 and a plurality of laser heads 1 in the drill body 3, also contains the adjustment frame 7 that can move camera 8 and / or laser head 1 in the drill body 3, the head of drill body 3 The part contains through holes corresponding to camera 8 and laser head 1, such as figure 1 shown.

[0032] The drill body 3 contains an installation cavity, and the adjustment frame 7 is arranged in the installation cavity, and the adjustment frame 7 is in contact with the inner wall of the drill body 3 . After the adjusting frame 7 is set, the adjusting frame 7 can drive the camera 8 and the laser head 1 to move back and forth along the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com