A toilet seat pre-flush device

A toilet seat and pre-flush technology, applied in the field of sanitary ware, can solve the problems of waste and difficulty in rinsing, and achieve the effects of saving space, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

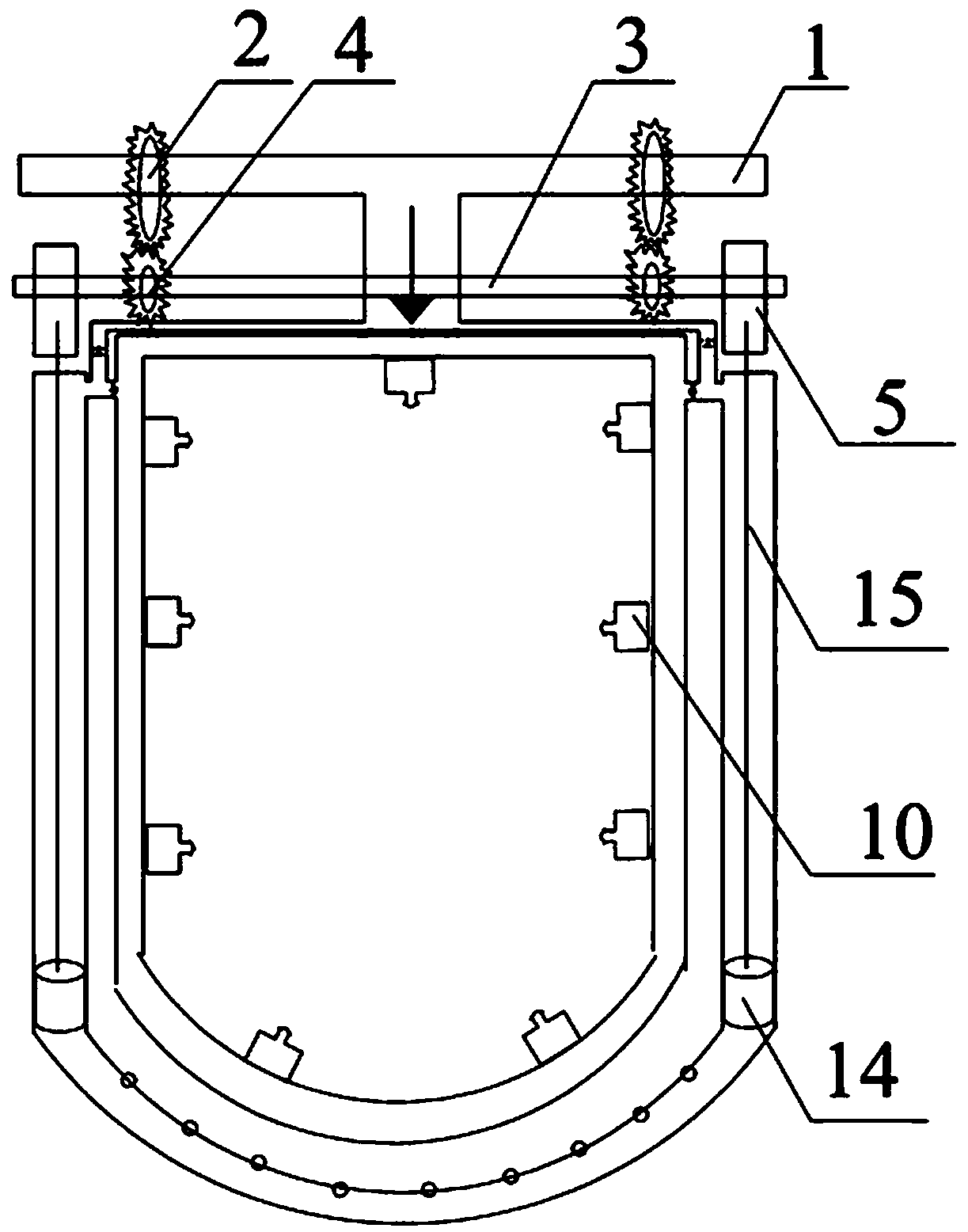

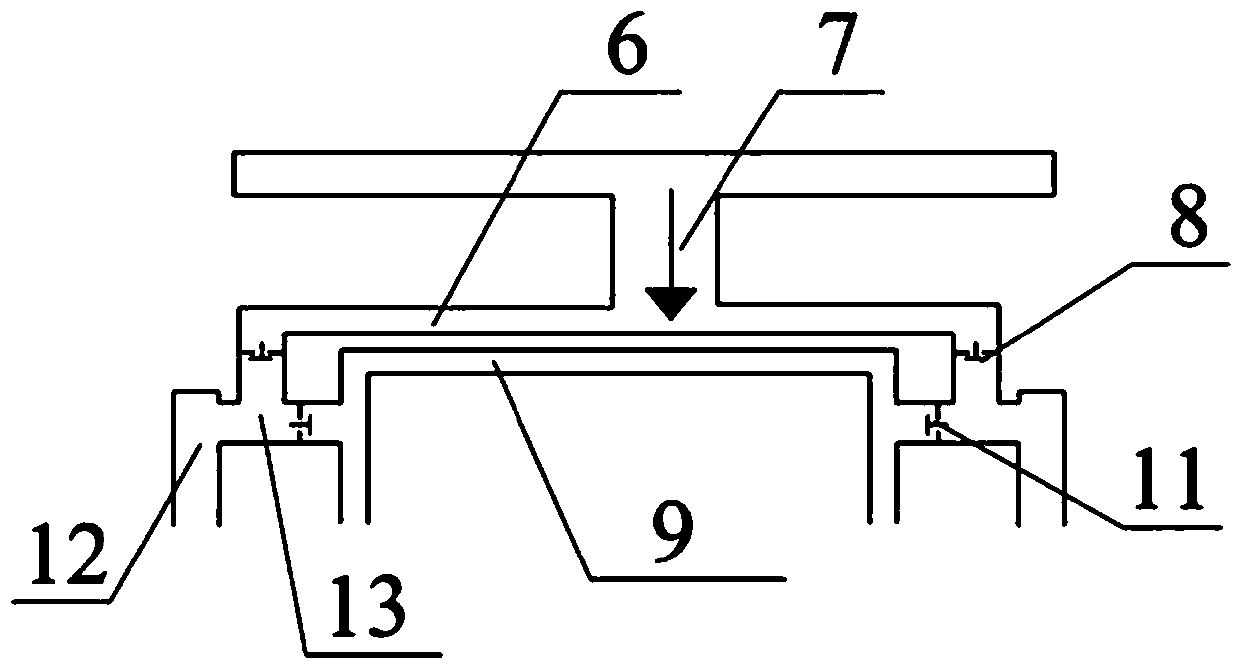

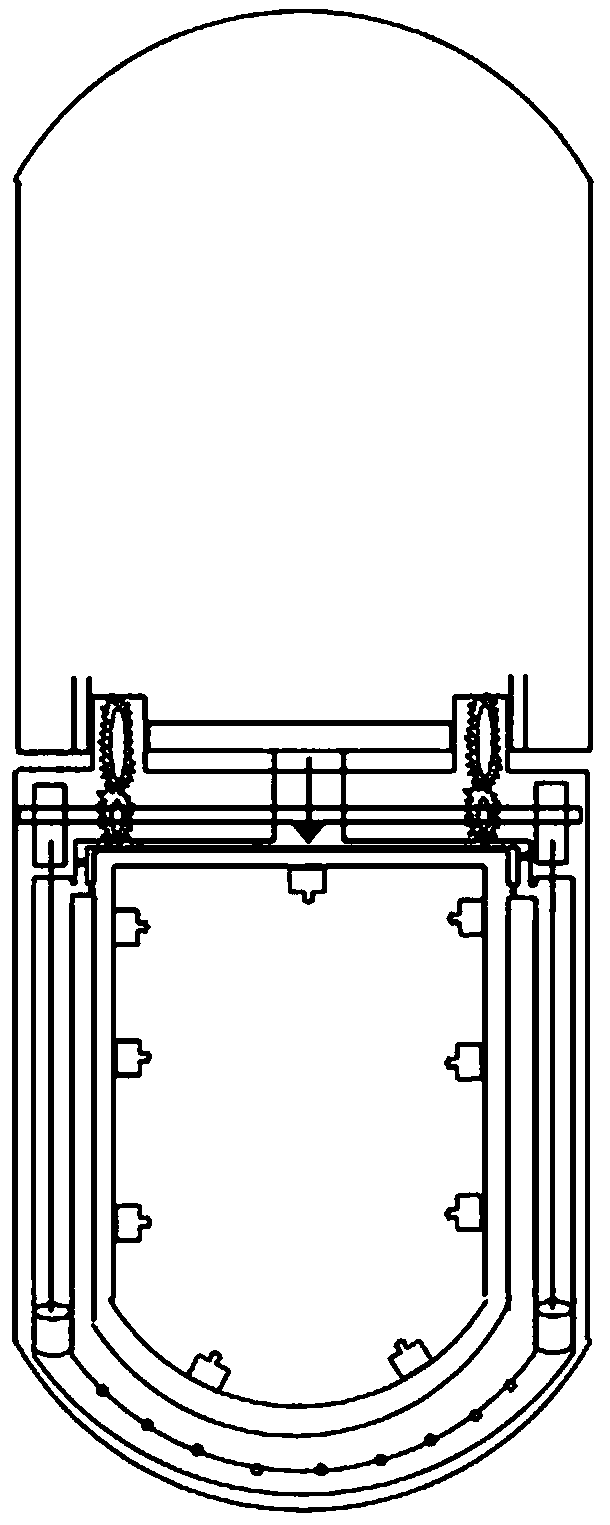

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0033] Such as Figure 1-5 As shown, the present invention provides a toilet seat pre-flush device, which is installed inside the toilet seat to save space, and the whole pre-flush device can be controlled by simple actions of putting down and picking up the toilet seat, without installing additional switches. Pre-washing, simple structure and easy operation. include:

[0034] The first shaft 1 is fixed on the upper part of the toilet bowl, a pair of first gears 2 are pierced at both ends, and a first water inlet and a first water outlet are opened in the middle, and the first water inlet is connected with the water tank;

[0035] The second shaft 3 is arranged parallel to the first shaft 1, a pair of second gears 4 meshing with the pair of first gears 2 are pierced on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com