Thermal expansion coefficient adjustable Cu heat sink and preparation method thereof

A thermal expansion coefficient and heat sink technology, applied in lasers, electrical components, circuits, etc., can solve the problems of large thermal expansion coefficient of metal heat sinks, poor thermal conductivity of ceramic heat sinks, and high price, so as to reduce internal stress and reduce energy consumption. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The method for preparing the above-mentioned Cu heat sink with adjustable thermal expansion coefficient mainly includes two stages of green compact preparation and sintering to prepare the heat sink. The sintering preparation of the heat sink is divided into three processes: preheating, reaction and densification, specifically including the following steps:

[0035] Step 1. Compaction preparation:

[0036] Weighing 20-80vol.% Cu powder and 20-80vol.% mixed powder into the mixer, mixing evenly, adding to a stainless steel mold, pressing and forming to obtain a green compact;

[0037] Wherein, the mixed powder is one of the mixed powder of Ti powder and B powder, the mixed powder of Zr powder and B powder, the mixed powder of Ti powder and C powder, and the mixed powder of Zr powder and C powder; In the mixed powder of Ti powder and B powder, the amount of substance ratio of Ti powder and B powder is 1:2; In the mixed powder of Zr powder and B powder, the amount of substa...

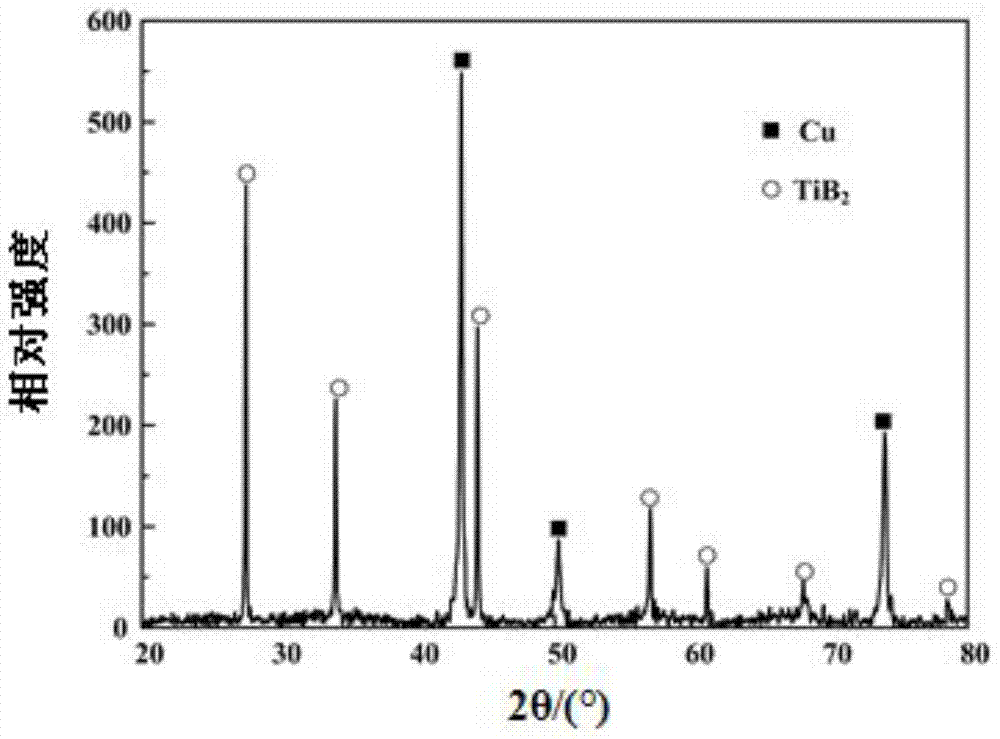

Embodiment 1

[0053] Cu heat sink with adjustable thermal expansion coefficient, its composition is: 80vol.% Cu and 20vol.% TiB 2 .

[0054] The preparation method of the above-mentioned Cu heat sink with adjustable thermal expansion coefficient:

[0055] Step 1. Put 88.80g of Cu powder with a particle size of 50μm, 7.68g of Ti powder with a particle size of 25μm and 3.52g of B powder with a particle size of 1μm into the mixer for 6 hours; then put the uniformly mixed powder into the stainless steel In the mold, pressed into a billet;

[0056] Step 2. Place the green compact in the graphite mold in the sintering furnace. After vacuuming, inject high-purity argon gas of 1 atmosphere for protection. Heat the sintering furnace to 300°C for preheating and heat preservation for 25 minutes;

[0057] Step 3. Continue heating the sintering furnace to 800°C for 8 minutes, and the tungsten-rhenium thermocouple detects a sudden and rapid increase in the temperature of the green compact, indicating t...

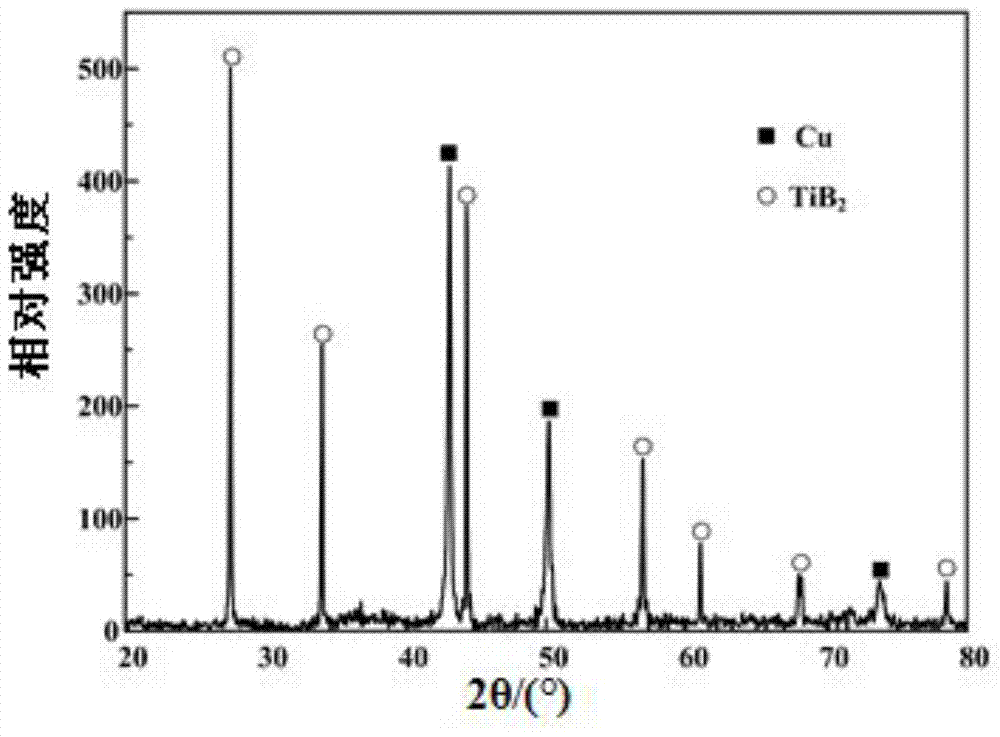

Embodiment 2

[0061] Cu heat sink with adjustable thermal expansion coefficient, its composition is: 60vol.% Cu and 40vol.% TiB 2 .

[0062] The preparation method of the above-mentioned Cu heat sink with adjustable thermal expansion coefficient:

[0063] Step 1. Put 74.83g of Cu powder with a particle size of 45μm, 17.26g of Ti powder with a particle size of 20μm and 7.91g of B powder with a particle size of 1μm into the mixer for 7 hours; then put the evenly mixed powder into the stainless steel In the mold, pressed into a billet;

[0064] Step 2. Place the green compact in the graphite mold in the sintering furnace. After vacuuming, inject high-purity argon gas of 1 atmosphere for protection. Heat the sintering furnace to 300°C for preheating and heat preservation for 28 minutes;

[0065] Step 3. Continue heating the sintering furnace to 800°C for 7 minutes, and the temperature measured by the tungsten-rhenium thermocouple increases rapidly, indicating that a reaction has occurred betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com