Treatment method of low-grade gold ore

A treatment method and low-grade technology, applied in the field of metallurgy, can solve the problems of high cost, impossibility of pre-granulation and desliming treatment, long cycle, etc., and achieve the effect of preventing decomposition, improving gold leaching efficiency, and short spraying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

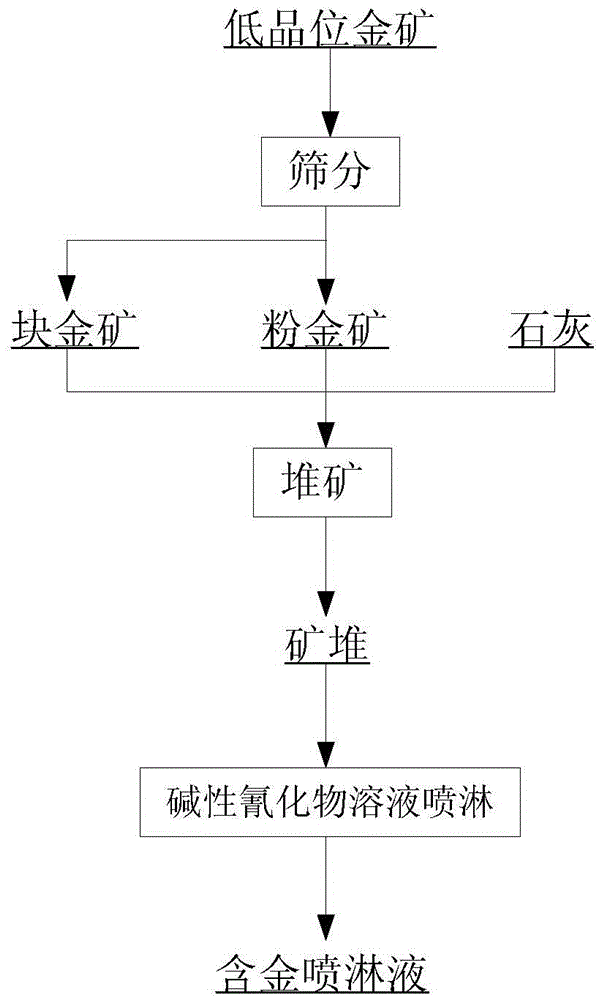

[0055] The ore is a low-grade oxidized gold ore with a gold grade of 0.3-1g / t and a natural particle size of less than 20cm.

[0056] 1. Screening: to obtain nugget ore with an average particle size of 5.5 cm and powder gold ore with an average particle size of 0.5 cm;

[0057] 2. Heaping: Mix nugget and fine gold ore at a ratio of 3:1, and add lime to the ore at a ratio of 2.8-3.5 kg / ton. The ore blending requires uniform ore blending.

[0058] 3. Turning: Use an excavator to turn the pile, the depth is 2.5-3.5m, until the loose layer is reached, and the flatness of the top surface reaches the visual judgment without obvious unevenness.

[0059] 4. Pipe support: According to the requirements of spray intensity, the distance between two adjacent nozzles on the sprinkler device is determined to be 4m; the nozzles are perpendicular to the horizontal direction, and the spray coverage rate is determined to be 100%.

[0060] 5. Spraying: After the debugging of the spraying pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com