Method for producing short-chain volatile fatty acids by utilizing kitchen wastes and short-chain volatile fatty acids

A technology of volatile fatty acids and kitchen waste, applied in fermentation and other directions, to achieve the effect of promoting hydrolysis, high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

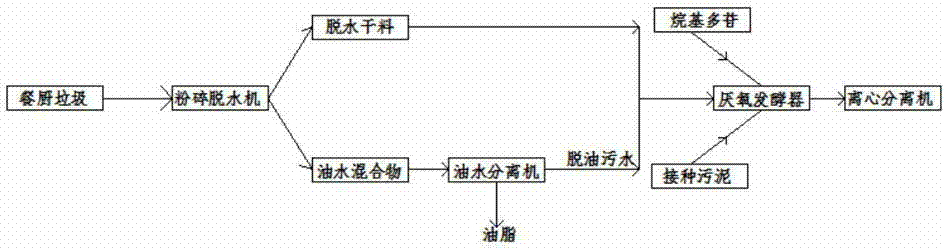

[0036] see figure 1 A method for producing short-chain volatile fatty acids from kitchen waste, specifically comprising the following steps:

[0037] (1) Pretreatment of food waste: Remove wooden chopsticks, napkins, glass ceramic pieces, bones, fish bones and other substances that are not conducive to fermentation in food waste. Then use a pulverizer to pulverize to less than 0.3 cm, and then use a dehydrator to separate the pulverized food waste into two parts: dehydrated dry material and oil-water mixture. The oil-water mixture is discharged into the oil-water separator for oil-water separation to obtain deoiled sewage. Mix the deoiled sewage with the dehydrated dry material, the solid content is 15%, VS (volatile solids) / TS (total solids) = 95.3%; complete the pretreatment of kitchen waste.

[0038] (2) Inoculation sludge: It was taken from the excess sludge discharged from the secondary sedimentation of Changsha No. 1 Sewage Treatment Plant. After testing, the microorga...

Embodiment 2

[0042] The method for producing short-chain volatile fatty acids from kitchen waste specifically comprises the following steps:

[0043] (1) Pretreatment of food waste: Remove wooden chopsticks, napkins, glass ceramic pieces, bones, fish bones and other substances that are not conducive to fermentation in food waste. Then use a pulverizer to pulverize to less than 0.3 cm, and then use a dehydrator to separate the pulverized food waste into two parts: dehydrated dry material and oil-water mixture. The oil-water mixture is discharged into the oil-water separator for oil-water separation to obtain deoiled sewage. Mix deoiled sewage with dehydrated dry material, with a solid content of 15%, VS / TS=95.3%; complete the pretreatment of kitchen waste.

[0044] (2) Inoculation sludge: It was taken from the excess sludge discharged from the secondary sedimentation of Changsha No. 1 Sewage Treatment Plant. After testing, the microorganisms in the excess sludge were mainly hydrolyzed and ...

Embodiment 3

[0048] (1) Pretreatment of food waste: Remove wooden chopsticks, napkins, glass ceramic pieces, bones, fish bones and other substances that are not conducive to fermentation in food waste. Then use a pulverizer to pulverize to less than 0.3 cm, and then use a dehydrator to separate the pulverized food waste into two parts: dehydrated dry material and oil-water mixture. The oil-water mixture is discharged into the oil-water separator for oil-water separation to obtain deoiled sewage. Mix deoiled sewage with dehydrated dry material, with a solid content of 15%, VS / TS=95.3%; complete the pretreatment of kitchen waste.

[0049] (2) Inoculation sludge: It was taken from the excess sludge discharged from the secondary sedimentation of Changsha No. 1 Sewage Treatment Plant. After testing, the microorganisms in the excess sludge were mainly hydrolyzed and fermented microorganisms; specifically, they were obligate anaerobic Clostridium Bacteroides, Bacteroides, Butyvibrio, Bifidobacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com