PAMAM (polyamide-amine)-modified water-soluble upconversion nanoparticles and preparation method thereof

A nanoparticle, water-soluble technology, applied in the field of nanomaterials, can solve the problems of poor water solubility and biocompatibility, limited applications, etc., and achieve the effects of good water solubility, high luminous intensity, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

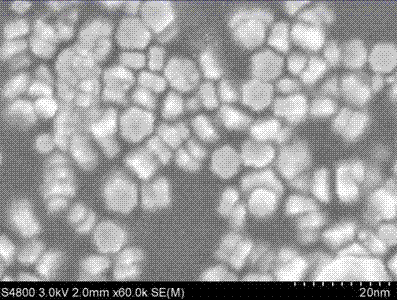

Image

Examples

Embodiment 1

[0020] 0.78mmol of YCl 3 , 0.2mmol of YbCl 3 , 0.02mmol of ErCl 3 5mL methanol solution, 6mL oleic acid OA and 15mL 1-octadecene ODE were ultrasonically mixed, heated to 150°C under argon protection, and kept for 30 minutes to form a light yellow solution, then cooled to 50 °C, add NH containing 0.16g ammonium fluoride 4 F and 0.10g NaOH in methanol solution, sonicated for 30 minutes, then slowly heated to 110°C and maintained for 1h to remove methanol and residual water, then heated to 320°C at a rate of 1°C / min under the protection of argon , kept for 2 hours, then naturally cooled to room temperature, added absolute ethanol, centrifuged to obtain a precipitate, and then washed repeatedly with water and ethanol, and finally obtained up-converting nanoparticles (UCNPs) that can be dissolved in various organic solvents such as cyclohexane.

[0021] Mix 1g / L of 5mL up-converting luminescent nanoparticles hexane dispersion solution with 0.6g / L of 5mL nitrosonium tetrafluorobo...

Embodiment 2

[0024] 0.69 mmol YCl 3 , 0.3mmol of YbCl 3 , 0.01mmol of ErCl 3 5 mL of methanol solution, 6 mL of oleic acid OA and 15 mL of 1-octadecene ODE were ultrasonically mixed, heated to 150 ° C under argon protection, and kept for 30 minutes to form a light yellow solution, and then cooled to 50°C, add NH containing 0.16g ammonium fluoride 4 F and 0.10g NaOH in methanol solution, sonicated for 30 minutes, then slowly heated to 110°C and maintained for 1h to remove methanol and residual water, then heated to 320°C at a rate of 1°C / min under the protection of argon , kept for 2 hours, then naturally cooled to room temperature, added absolute ethanol, centrifuged to obtain a precipitate, and then washed repeatedly with water and ethanol, and finally obtained up-converting nanoparticles (UCNPs) that can be dissolved in various organic solvents such as cyclohexane.

[0025] Mix 2g / L of 5mL up-converting luminescent nanoparticles hexane dispersion solution with 0.3g / L of 5mL nitrosoniu...

Embodiment 3

[0027] 0.78mmol of YCl 3 , 0.2mmol of YbCl 3 , 0.02mmol of TmCl 35 mL of methanol solution, 6 mL of oleic acid OA and 15 mL of 1-octadecene ODE were ultrasonically mixed, heated to 150 ° C under argon protection, and kept for 30 minutes to form a light yellow solution, and then cooled to 50°C, add NH containing 0.16g ammonium fluoride 4 F and 0.10g NaOH in methanol solution, sonicated for 30 minutes, then slowly heated to 110°C and maintained for 1h to remove methanol and residual water, then heated to 320°C at a rate of 1°C / min under the protection of argon , kept for 2 hours, then naturally cooled to room temperature, added absolute ethanol, centrifuged to obtain a precipitate, and then washed repeatedly with water and ethanol, and finally obtained up-converting nanoparticles (UCNPs) that can be dissolved in various organic solvents such as cyclohexane.

[0028] Mix 2g / L of 5mL up-converting luminescent nanoparticles hexane dispersion solution with 0.6g / L of 5mL nitrosoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com