Method for treating wastewater by virtue of multi-stage catalytic oxidation, micro electrolysis and multi-effect evaporation

A catalytic oxidation and micro-electrolysis technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, anaerobic digestion treatment, etc., can solve problems such as limiting the popularization and application of Fenton method, consuming manpower and material resources, and increasing labor intensity. , to achieve good coagulation effect, low investment cost, convenient operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

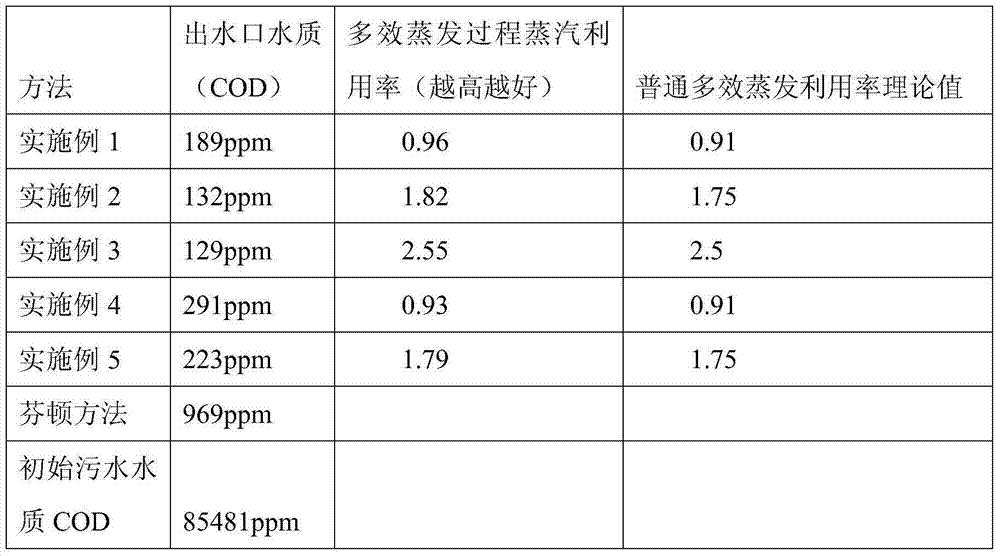

Examples

Embodiment 1

[0035] The method for treating waste water by the described multistage catalytic oxidation plus micro-electrolysis method comprises the following steps:

[0036] (1) Firstly, filter the raw water flowing into the adjustment tank with three-stage bag filter, and then use the gas explosion method for 30 minutes to carry out the pretreatment process.

[0037] (2) Use hydrochloric acid to adjust the PH value of the raw water treated in step (1) to 3, and then enter the fiber ball filter for 30 minutes to degas and acidify to filter, and filter out the product of acid precipitation; the addition of hydrochloric acid is the total mass of raw water 0.3 ‰.

[0038] (3) The waste water filtered in step (2) enters the reaction tower equipped with micro-electrolysis fillers in the way of low inflow and high outflow, and uses the micro-electrolysis fillers to generate a "primary battery" effect to treat the wastewater.

[0039] (4) Add hydrogen peroxide to the waste water treated by micr...

Embodiment 2

[0045] The method for treating waste water by the described multistage catalytic oxidation plus micro-electrolysis method comprises the following steps:

[0046] (1) Firstly, filter the raw water flowing into the adjustment tank with three-stage bag filter, and then use the gas explosion method for 60 minutes to carry out the pretreatment process.

[0047] (2) Use hydrochloric acid to adjust the PH value of the raw water treated in step (1) to 4, explode the acid for 35 minutes and enter the fiber ball filter for filtration, and filter out the product of acid precipitation; the addition of hydrochloric acid is the total mass of raw water 0.3 ‰.

[0048] (3) The waste water filtered in step (2) enters the reaction tower equipped with micro-electrolysis fillers in the way of low inflow and high outflow, and uses the micro-electrolysis fillers to generate a "primary battery" effect to treat the wastewater.

[0049] (4) Add hydrogen peroxide to the waste water treated by micro-el...

Embodiment 3

[0055] The method for treating waste water by the described multistage catalytic oxidation plus micro-electrolysis method comprises the following steps:

[0056] (1) Firstly, the raw water flowing into the regulating tank is filtered by three-stage bag, and then the pretreatment process is carried out by using the explosion method for 90 minutes.

[0057] (2) Use hydrochloric acid to adjust the PH value of the raw water treated in step (1) to 3, degas the acid and analyze it for 40 minutes and enter the fiber ball filter for filtration, and filter out the product of acid precipitation; the addition of hydrochloric acid is the total mass of raw water 0.3 ‰.

[0058] (3) The waste water filtered in step (2) enters the reaction tower equipped with micro-electrolysis fillers in the way of low inflow and high outflow, and uses the micro-electrolysis fillers to generate a "primary battery" effect to treat the wastewater.

[0059] (4) Add hydrogen peroxide to the wastewater treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com