Method for rapidly starting anaerobic ammoxidation by utilizing anaerobic filter

A technology of anaerobic ammonium oxidation and anaerobic filter, which is applied in the field of sewage treatment, can solve the problems of slow growth, difficulty in bacterial colony enrichment and cultivation, difficulty in quick start-up of anaerobic ammonium oxidation reactor, etc., so as to accelerate the start-up process and promote rapid Good effect of domestication and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The method for quickly starting anaerobic ammonium oxidation with an anaerobic filter with a volume of 11L is as follows:

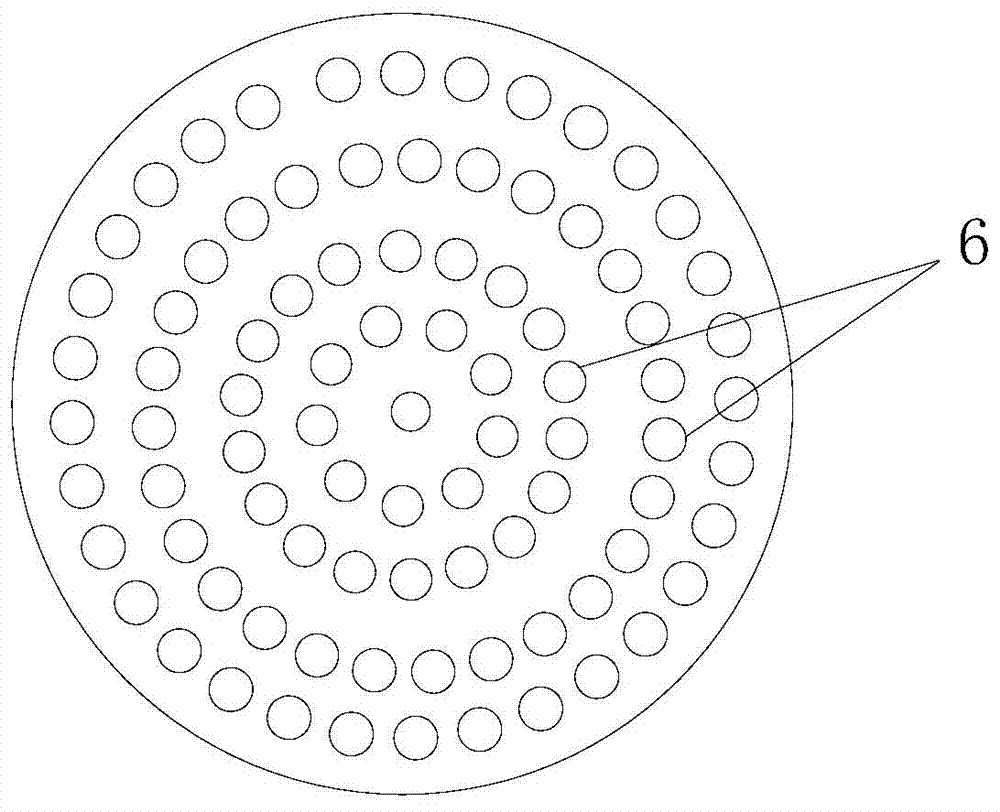

[0048] (1) Select a suspension ball filler with a diameter of 20 mm and soak it in the denitrification sedimentation sludge for 30 hours;

[0049] (2) Fill the filler treated in step (1) in the anaerobic filter, add nutrient solution to the anaerobic filter design capacity in the anaerobic filter, the nutrient solution water quality is EDTA5000mg / L, NaHCO 3 500mg / L, KH 2 PO 4 20mg / L, FeSO 4 1000mg / L, Fe 2 (SO 4 ) 3 3000mg / L, MgSO 4 200mg / L, CuSO 4 100mg / L;

[0050] (3) Denitrification activated sludge film formation stage

[0051] Use denitrification activated sludge to wash the filler from top to bottom. The operation method is: use a peristaltic pump to hang the denitrification activated sludge on the filler. The water inlet method is the upper inlet and the lower outlet. Twice a day, with an interval of 12 hours, 30 minutes each time, ...

Embodiment 2

[0063] The method for quickly starting anaerobic ammonium oxidation with an anaerobic filter with a volume of 11L is as follows:

[0064] (1) Select a suspension ball filler with a diameter of 25 mm and soak it in the denitrification sedimentation sludge for 24 hours;

[0065] (2) Fill the filler treated in step (1) in the anaerobic filter, add nutrient solution to the anaerobic filter design capacity in the anaerobic filter, the nutrient solution water quality is EDTA10000mg / L, NaHCO 3 1000mg / L, KH 2 PO 4 30mg / L, FeSO 4 2000mg / L, Fe2(SO 4 ) 3 5000mg / L, MgSO 4 500mg / L, CuSO 4 200mg / L;

[0066] (3) Denitrification activated sludge film formation stage

[0067] Use denitrification activated sludge to wash the packing from top to bottom. The operation method is: use a peristaltic pump to return the denitrification activated sludge. times, the time interval is 12h, each time is 30min, and the water inflow rate is 10L / min·m 3 Pool capacity, the amount of denitrification a...

Embodiment 3

[0079] Volume is 1m 3 The method for quickly starting anaerobic ammonium oxidation in the pilot test of the anaerobic filter for dry cleaning pig farm wastewater, the steps are as follows:

[0080] (1) Select a suspension ball filler with a diameter of 30 mm and soak it in the denitrification sedimentation sludge for 36 hours;

[0081] (2) Fill the filler treated in step (1) in the anaerobic filter, add nutrient solution to the anaerobic filter design capacity in the anaerobic filter, the nutrient solution water quality is EDTA6000mg / L, NaHCO 3 500mg / L, KH 2 PO 4 20mg / L, FeSO 4 1500mg / L, Fe 2 (SO 4 ) 3 3000mg / L, MgSO 4 300mg / L, CuSO 4 100mg / L;

[0082] (3) Denitrification activated sludge film formation stage

[0083]After step (2), use denitrifying activated sludge to rinse the packing from top to bottom. The operation method is: reflow the activated sludge, the water inlet method is the upper inlet and the lower outlet, and the rinsing rate is one Twice a day, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com