Method and special apparatus for improving surface purity and surface cleanliness of silicon carbide particles

A silicon carbide particle and cleanliness technology, which is applied in the production and processing of silicon carbide particle materials, can solve the problems of high energy consumption for drying, unfavorable large-scale industrial production, and many production links, so as to improve surface purity and surface cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

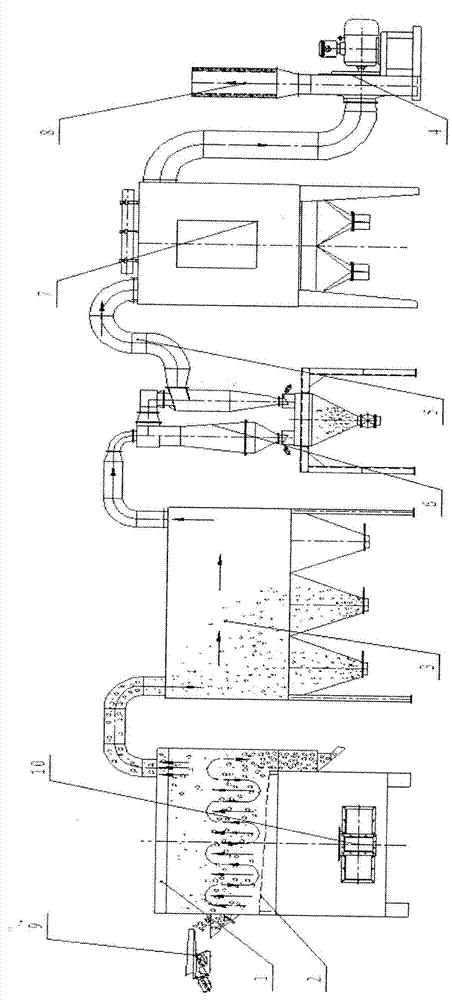

Image

Examples

example 1

[0043] Example 1. Improve surface purity and surface cleanliness for silicon carbide particle materials with a single particle size:

[0044]The silicon carbide particle material with a single particle size is the material after screening, and the particle size distribution has been fixed. When this method is used for processing, it can be directly sent into the vibration chamber by the feeding system. The strength of the air column is adjusted based on the finer particles. Re-screening is required.

example 2

[0045] Example 2. Improve surface purity and surface cleanliness for silicon carbide particle materials with mixed particle sizes:

[0046] Silicon carbide particle materials with mixed particle size numbers are unscreened materials, and the particle size distribution span is very large. Before using this method for processing, it is necessary to concentrate the similar particle size numbers separately, and use this method to process them separately. Adjust the air column strength to make the mixed particle size number the smallest. The grain is used as the benchmark, and the processed material enters the back-end screening system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com