Reversal inspecting device for packaging machine

A technology of turning device and turning shaft, which is applied in the direction of packaging, transportation and packaging, conveyor objects, etc., and can solve the problems of high labor intensity, time-consuming and laborious, and easy missing inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

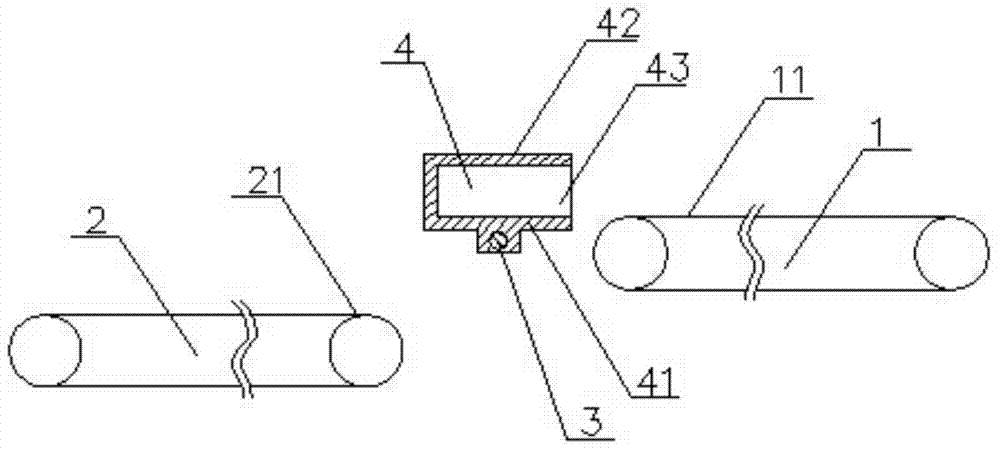

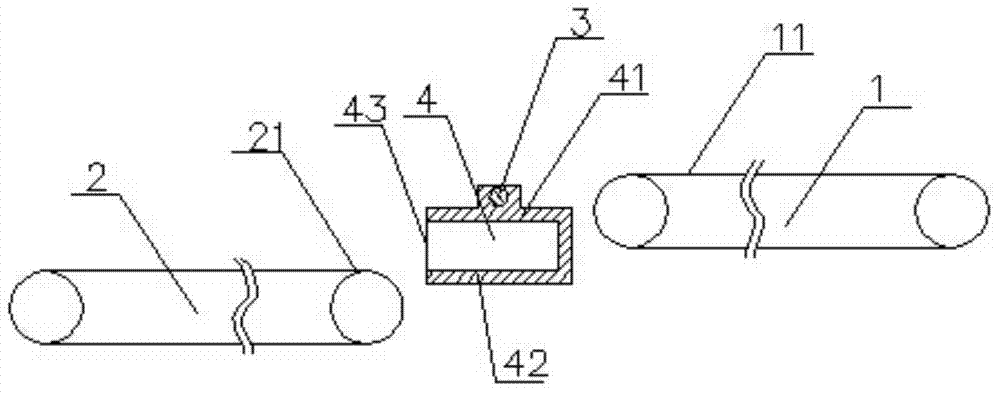

[0013] see figure 1 and figure 2 , as shown in the legend therein, an overturn checking device of a packaging machine is used for overturning and checking items to be inspected, including a first belt conveyor 1, an overturning device, and a second belt conveyor 2 arranged in sequence along a set direction, The first belt conveyor 1 has the first conveying surface 11 displaced along the above-mentioned setting direction, the second belt conveyor 2 has the second conveying surface 21 displaced along the above-mentioned setting direction, and the above-mentioned overturning device includes an overturning shaft 3 and The hopper 4 connected to the turning shaft 3, the turning shaft 3 has a degree of freedom to rotate in a vertical plane parallel to the above-mentioned set direction, the hopper 4 has a first receiving plate 41, a second receiving plate 42 and a hopper inlet 43, the second A receiving plate 41 and a second receiving plate 42 are set up and down opposite to each ot...

Embodiment 2

[0016] The rest is the same as the first embodiment, the difference is that a positioning device is also provided in the above-mentioned hopper, and the above-mentioned positioning device has a degree of freedom of displacement along the above-mentioned setting direction. When the item to be checked is small, the inner part of the hopper can be The cavity is reduced in size so that the item to be checked partially rests on the conveying surface of the belt conveyor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com