Mechanical activation reactor capable of enhancing polysaccharide high polymer modification

A polymer modification and mechanical activation technology, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problem of uneven heating of materials, local temperature rise, and large loss of raw materials and other problems, to achieve the effect of improving the uniformity of replacement, solving the problem of material bonding, and uniform material reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

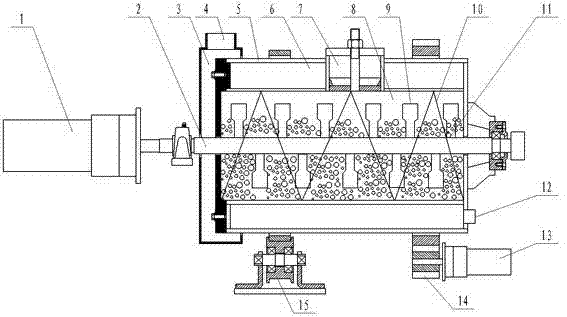

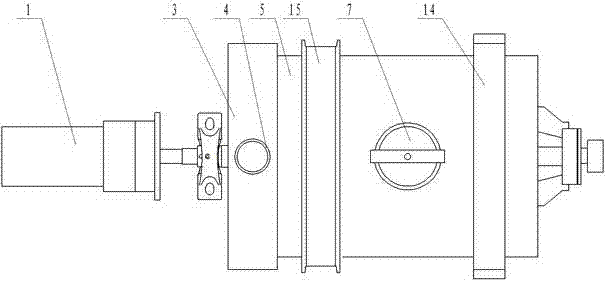

[0035]A mechanical activation reactor for strengthening polysaccharide polymer modification, the outer cylinder 5 is a horizontal structure, the outer cylinder 5 is equipped with a grinding inner cylinder 8, the reducer I1 is connected to the stirring shaft 2 through a coupling, and the stirring The shaft 2 is inserted into the grinding inner cylinder 8 through the through hole on the end cover 3 of the outer cylinder 5, and the stirring shaft 2 is fixed on the two ends of the outer cylinder 5 through the bearing seats at both ends; A jacket 6 with a heating device, the heating device includes a heating medium and a heater, wherein the heating medium is heat transfer oil, and the heater is an electric heater. A temperature controller 12 is provided inside the jacket 6 . There is a material inlet and outlet 7 above the outer cylinder 5, and the material inlet and outlet 7 communicates with the grinding inner cylinder 8, and the grinding inner cylinder 8 is provided with grindin...

Embodiment 2

[0038] The difference from Embodiment 1 is that, during installation, the outermost end of the scraping ribbon 10 is at a distance of 2mm from the inner wall of the grinding inner cylinder 8 . The outer cylinder 5 is connected with the driving device, and the driving device includes a reducer II 13 and a gear set 14 installed on the outer cylinder 5; the reducer II 13 controls the rotation of the outer cylinder 5 by meshing with the gear set 14 . The outer ring of the outer cylindrical body 5 is provided with supporting rollers 15 . The heating medium in the jacket 6 is steam. The outer ring of the outer cylinder 5 is equipped with supporting wheels 15, which reduces the loss of the outer cylinder 5 in the turnover movement, improves the service life, and can adjust the inclination of the outer cylinder 5 through the supporting rollers 15 for different materials and modification methods The speed and rotation speed are used to control the residence time of the material in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com