Micro-fluidic chip having nano dendrite Raman substrate and manufacturing method thereof

A microfluidic chip and Raman substrate technology, applied in Raman scattering, chemical instruments and methods, laboratory utensils, etc., can solve problems such as failure to meet use requirements, low SERS activity, and low detection efficiency, and achieve savings Cost, simplified preparation process, effect of high SERS activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

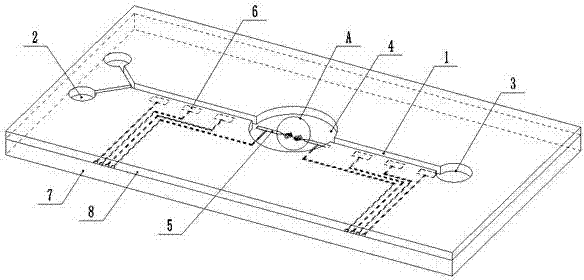

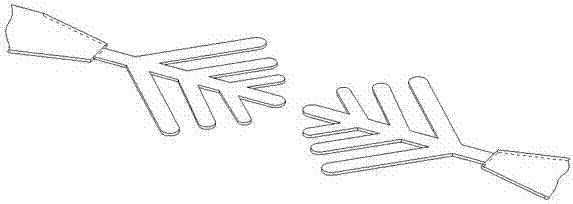

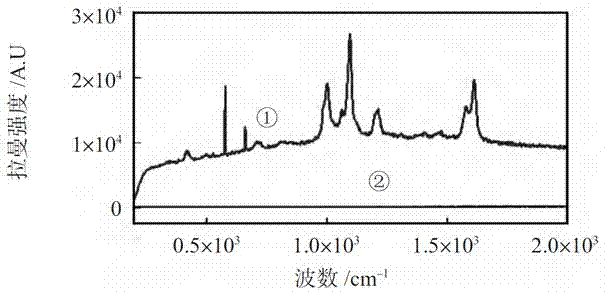

[0015] like figure 1 As shown, there is a microfluidic chip with a nanodendritic Raman substrate, the chip is provided with at least one microfluidic channel 1, and one end of the microfluidic channel 1 is provided with at least one sample pool 2, and each sample pool 2 is It communicates with the micro-channel 1 but does not communicate with each other. The other end of the micro-channel 1 is provided with at least one waste liquid pool 3, and each waste liquid pool 3 is connected with the micro-channel 1 but not connected to each other. Not connected, the micro-channel 1 is provided with at least one growth pool 4, and the micro-channel 1 passes through each growth pool 4, and at least one pair of first growth pools with tips are arranged in the growth pool 4. Electrodes 5, the two first electrodes 5 in each pair have the nano-dendrite structure of noble metal on the nearest tip, the noble metal is gold, platinum or palladium, the two first electrodes in each pair The dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com