Full-automatic low-energy-consumption warming system of greenhouse

A fully automatic, low-energy-consumption technology, applied in greenhouse cultivation, energy-saving measures, horticulture, etc., can solve the problems of energy loss, low initial temperature of transmission medium, and high heat, so as to reduce the cost of construction and operation, and flexible installation and adjustment Convenience and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

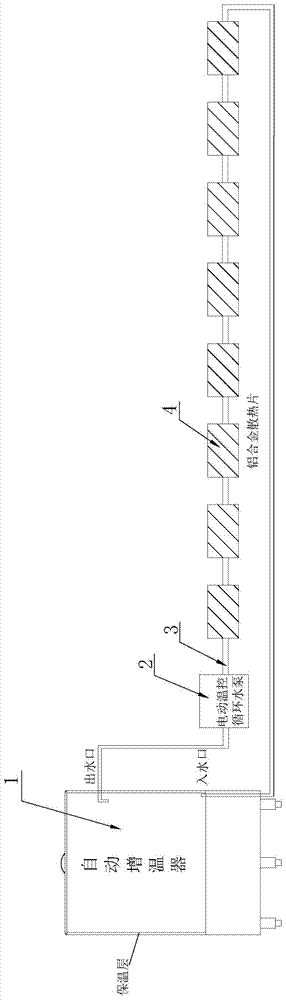

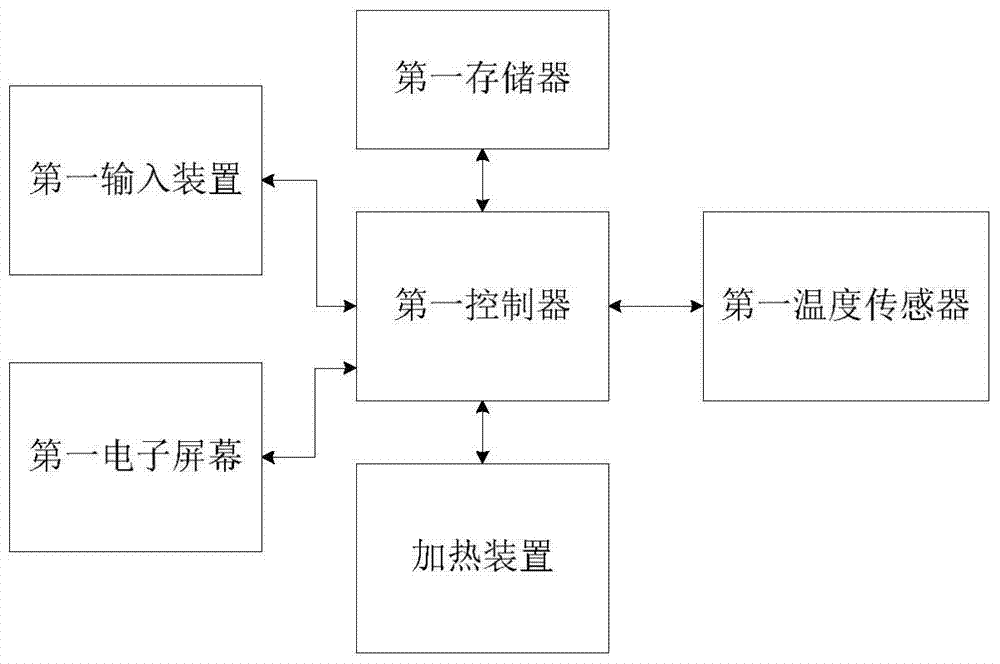

[0057] Example 1: Such as figure 1 As shown, the fully automatic low-energy consumption warming system for greenhouses provided in this embodiment includes an automatic warmer 1, an electric temperature-controlled circulating water pump 2, a water delivery pipe 3, and a cooling fin 4. The automatic warmer 1 includes a stainless steel shell, Stainless steel inner shell, the stainless steel inner shell is a liquid volume chamber, and the insulation layer treated by foaming technology is filled between the stainless steel outer shell and the stainless steel inner shell; The water outlet and the water inlet of the automatic warmer 1; the water outlet of the automatic warmer 1, the electric temperature-controlled circulating water pump 2, several heat sinks 4, and the water inlet of the automatic warmer 1 are connected in sequence through the water delivery pipe 3 to form a heat transfer cycle circuit; the outside of the heat sink 4 is coated with a heat absorbing coating.

[00...

Embodiment 2

[0077] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

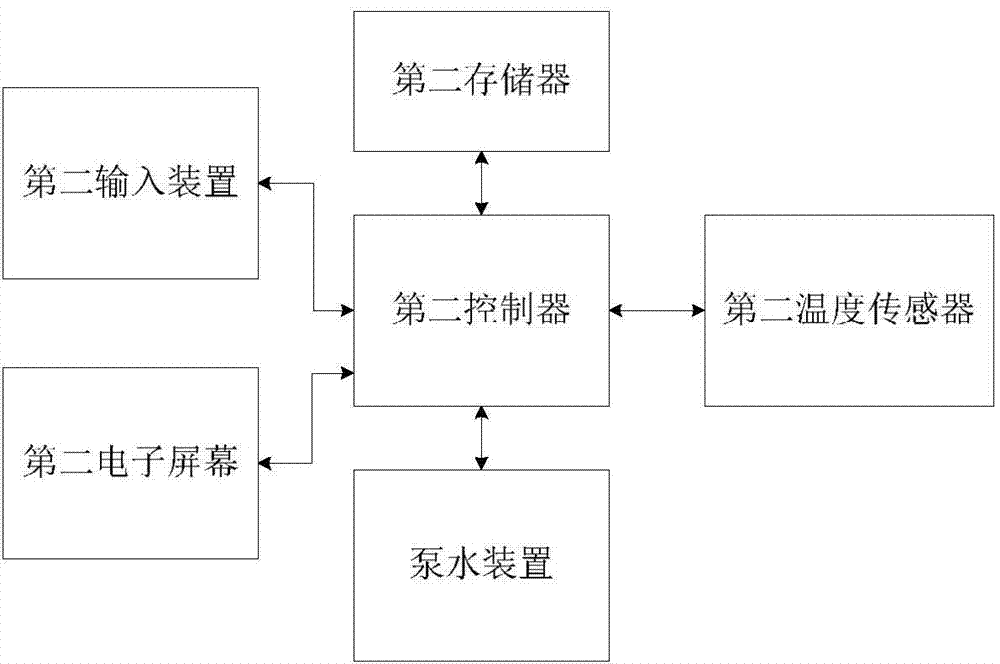

[0078] The first temperature sensor includes a room temperature sensor (not shown) arranged outside the stainless steel casing of the automatic warmer 1 for collecting room temperature in the shed (not shown in the figure), and a temperature sensor arranged in the liquid volume chamber of the automatic warmer 1 , a water temperature sensor (not shown in the figure) for collecting the water temperature in the volume chamber; the second temperature sensor includes a room temperature sensor (not shown in the figure) arranged outside the electric temperature-controlled circulating water pump 2 for collecting the room temperature in the shed shown), and a water temperature sensor (not shown in the figure) arranged inside the electric temperature-controlled circulating water pump 2 for collecting the water temperature in the water pump...

Embodiment 3

[0096] Example 3: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0097] In this embodiment, there are 12 aluminum alloy cooling fins connected in sequence, and the volume of the liquid volume chamber is 150L.

[0098] The first temperature sensor only includes a room temperature sensor arranged outside the stainless steel shell of the automatic warmer 1 for collecting the room temperature in the shed; the second temperature sensor only includes a room temperature sensor arranged outside the electric temperature-controlled circulating water pump 2 A room temperature sensor for the room temperature in the collection shed.

[0099] Of course, the first temperature sensor and the second temperature sensor can also share the same room temperature sensor, and the room temperature sensor is connected to the first controller of the automatic temperature increase control system and the second controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com