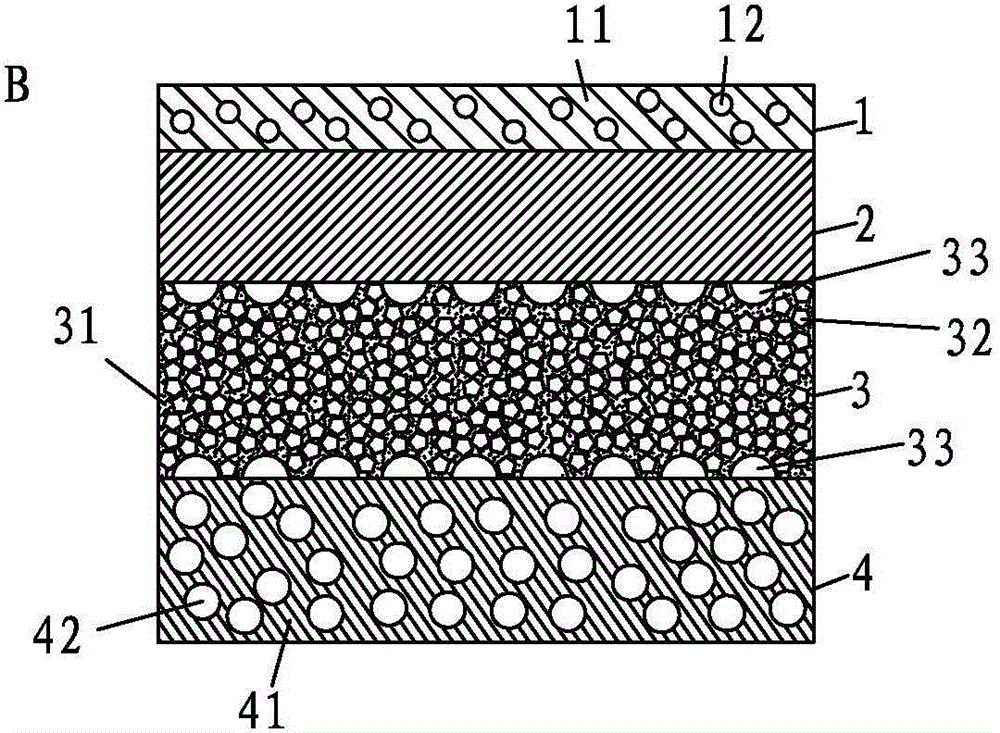

Multi-layer composite thermal insulation board and preparation method thereof

A technology of thermal insulation board and thermal insulation layer, which is applied in thermal insulation, heat exchange equipment, chemical instruments and methods, etc., can solve the problems of no thermal insulation effect and unsatisfactory effect, and achieves effective blocking of thermal transfer. , excellent aesthetics, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, specific embodiments of the present invention will be described in detail, but these descriptions are only used to schematically illustrate the present invention, and are not intended to limit the protection scope of the present invention.

[0027] First, the materials of each layer in the multilayer composite thermal insulation panel of the present invention will be described separately.

[0028] 1. Outer coating

[0029] The outer coating layer includes a first base body and hollow ceramic particles dispersed in the first base body. As the outermost layer of the multi-layer composite thermal insulation panel of the present invention, the above-mentioned outer coating realizes excellent aesthetics, weather resistance, corrosion resistance, water resistance and other properties through the first substrate. In addition, the effect of heat preservation and heat insulation is realized through hollow ceramic particles.

[0030] As the above-mentioned first su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com