Semi-open type self-cutting blocking-free pump impeller for shearing structure

A shear structure, non-clogging pump technology, applied in non-clogging pump impeller equipment, non-clogging pump impeller field, can solve the problems of sewage pump efficiency reduction, complex structure, shortened service life, etc., and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

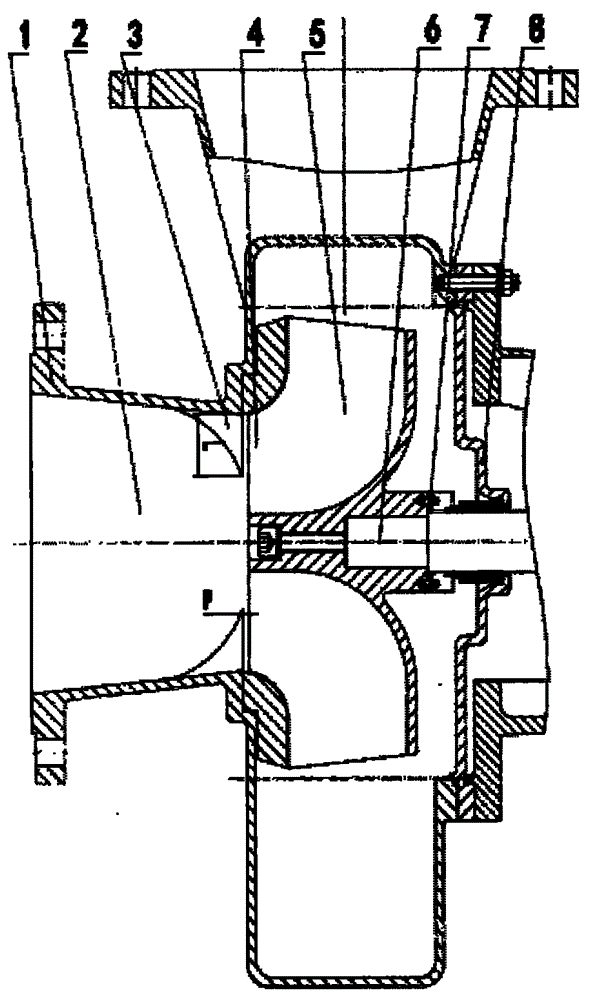

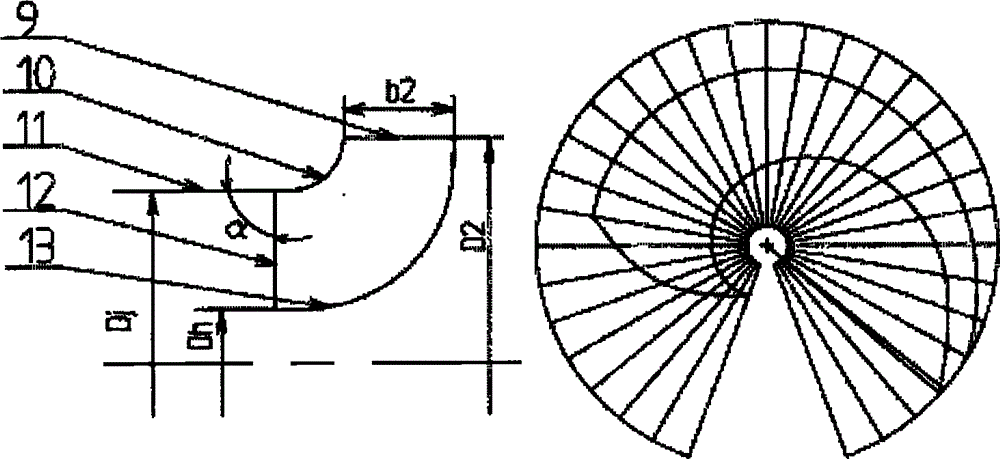

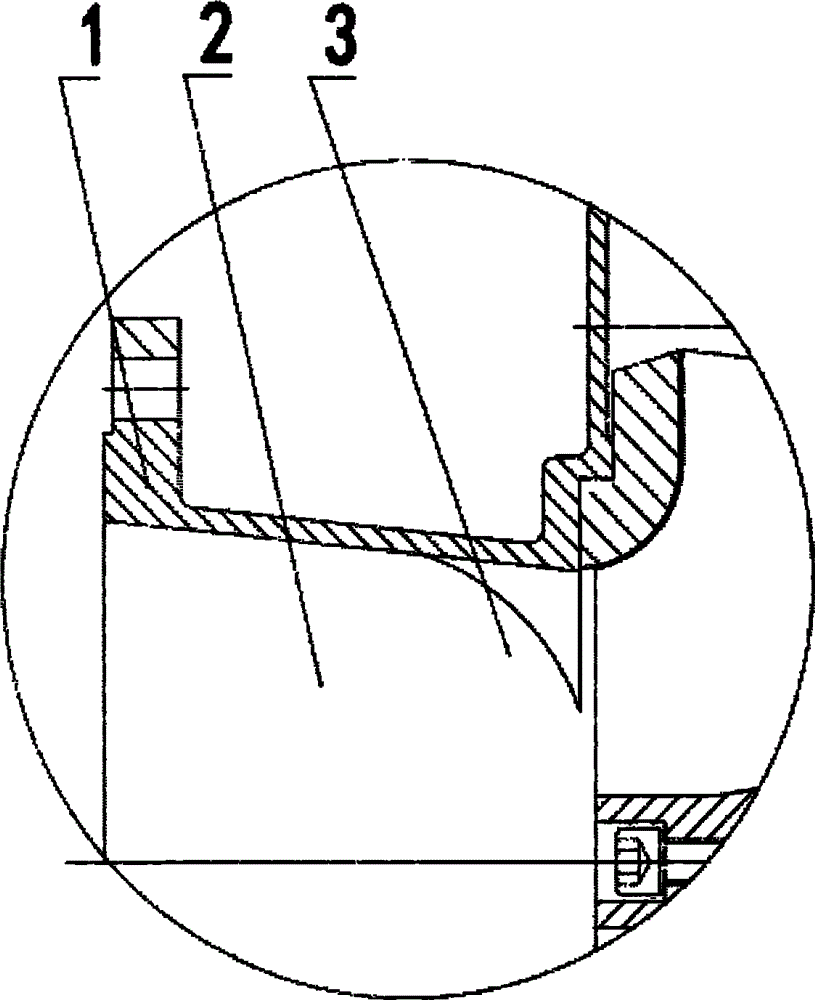

[0015] figure 1 It is a semi-open self-cutting impeller, which mainly includes pump body (1), suction port (2), shear cutter (3), blade (4), impeller (5), pump shaft (6), blade adjustment pad Sheet (7), pump cover (8), blade outlet (, 9), blade front streamline (10), blade inlet cylindrical surface (11), blade inlet edge (12), blade rear cover plate streamline (13) . The pump is connected with the drive motor shaft and installed in the pump volute. When the motor rotates, it drives the impeller to rotate, which can realize the transportation of sewage medium.

[0016] The impeller adopts a semi-open structure, which is characterized in that the front streamline (10) and the rear streamline (13) of the blade both extend forward toward the inlet side and extend to the cylindrical surface (11) of the impeller inlet. The axial plane projection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com