Method for quickly tunneling shed type supporting roadway

A shed-type bracket and cantilever-type roadheader technology, which is applied to support the roof beam of the mine roof, tunnels, earthwork drilling and mining, etc., can solve the problems of increasing the amount of renovation work, unrealized mechanized operations, and high labor intensity. The effect of reducing the time-consuming preparation process, reducing the time-consuming support process, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

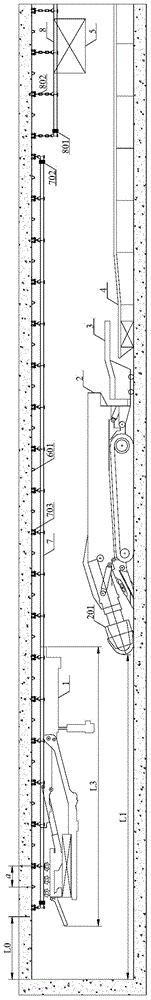

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1Shown is a monorail crane roadway support platform 1, including a protective shield 101, an advance support installation beam 102, an advance support support arm 103, a work platform support arm 104, a work platform 105, a special fixture 106, and a console 107 , main support arm beam 108, equipment stabilizer 109, pumping station 110, suspension device 111, travel brake device 112, maintenance platform 113, multiple hydraulic cylinders and pipelines; main support arm beam 108 is a monorail crane roadway support platform 1, the leading support arm 103, the working platform support arm 104 are hinged with the main support arm beam 108, the equipment stabilizer 109, the pump station 110, the suspension device 111 are fastened with the main support arm beam 108, and the braking The device 112 is connected with the main support arm beam 108 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com