A rapid construction method of offshore reinforced concrete frame structure

A reinforced concrete and frame structure technology, applied in the direction of embankment, pier, quay wall, etc., can solve the problems of poor maneuverability, poor wind and wave resistance, and inability to guarantee the progress of the project, so as to reduce construction safety risks and improve construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

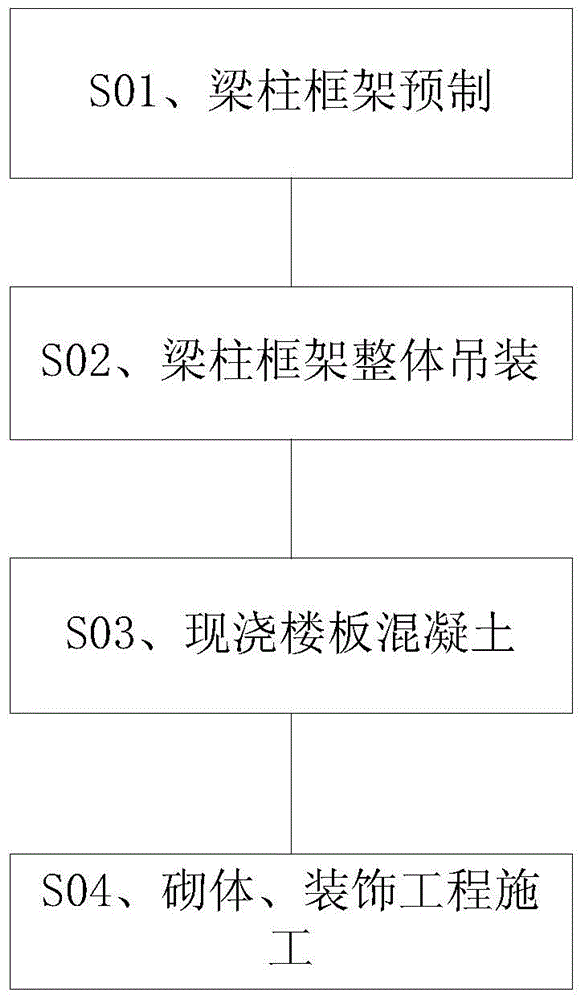

[0037] see figure 1 , the present embodiment discloses a rapid construction method of an offshore reinforced concrete frame structure, comprising the following steps:

[0038] S01. Beam-column frame prefabrication: use concrete to prefabricate a beam-column frame consisting of vertical columns and not less than one layer of horizontally criss-crossing beams in a flat and open location;

[0039] S02. Overall hoisting of the beam-column frame: when the concrete casting of the beam-column frame is completed and the strength reaches the design strength, it shall be transported by square barge and hoisted by a crane;

[0040] S03. Cast-in-place floor slab concrete: use a mixer ship or place a mixer on the platform for concrete mixing, and put the crane bucket into the warehouse for floor slab pouring;

[0041] S04. Construction of masonry and decoration works: construction of masonry and decoration works on beam-column frames.

[0042] The biggest improvement between the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com