A kind of preparation technology of hot melt adhesive omentum

A preparation process and technology of glue mesh membrane, which is applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of mesh membrane breaking, sticking mesh belt, and poor pore size uniformity of mesh membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

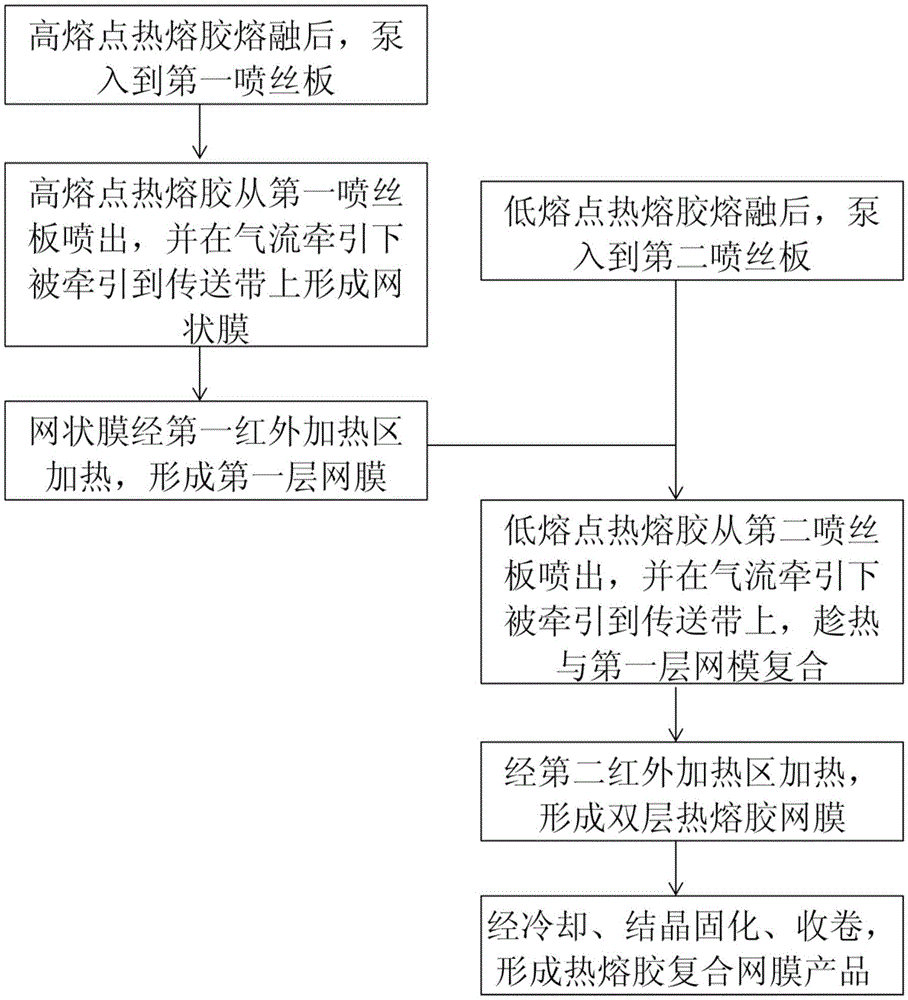

Method used

Image

Examples

Embodiment 1

[0020] The high melting point (DSC final melting point 135°C) hot melt adhesive and the low melting point (DSC final melting point 105°C) hot melt adhesive are melted and pumped into the independent first spinneret and the second spinneret; the two spinneret The distance between the plates is 1m, the conveyor belt (steel belt) works, and its transmission speed is 13m / min; open the first spinneret, adjust its internal temperature to 210°C, spinneret speed to 10m / min, airflow (compressed air) speed The high melting point hot melt adhesive is spun from the first spinneret to the conveyor belt under the airflow traction to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 100°C to form the first Layer omentum; open the second spinneret, adjust its internal temperature to 180°C, spinneret speed to 8m / min, air velocity (nitrogen) to 100m / min, low melting point hot melt adhesive from the second spinneret and The filaments are spun onto...

Embodiment 2

[0022] The high melting point (DSC final melting point 147°C) hot melt adhesive and the low melting point (DSC final melting point 73°C) hot melt adhesive are melted and then pumped into the independent first spinneret and second spinneret; the two spinnerets The distance between the plates is 1m, the conveyor belt (steel belt) is working, and the transmission speed is adjusted to 13m / min; the first spinneret is opened, and the internal temperature is adjusted to 220°C, the spinneret speed is 8m / min, and the airflow (nitrogen) speed 100m / min, the high-melting point hot melt adhesive is spun from the first spinneret to the conveyor belt under the airflow traction to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 110°C to form the first Layer omentum; open the second spinneret, adjust its internal temperature to 200°C, spinneret speed to 8m / min, air velocity (nitrogen) to 100m / min, low melting point hot melt adhesive from the se...

Embodiment 3

[0024] The high melting point (DSC final melting point 180°C) hot melt adhesive and the low melting point (DSC final melting point 100°C) hot melt adhesive are melted and then pumped into the independent first spinneret and second spinneret; the two spinneret The distance between the plates is 2m, the conveyor belt (steel belt) is working, and the transmission speed is adjusted to 15m / min; the first spinneret is opened, the internal temperature is adjusted to 240°C, the spinneret speed is 12m / min, and the air flow (compressed air) The speed is 100m / min, the high-melting point hot melt adhesive is spun from the first spinneret and drawn by the airflow to the conveyor belt to form a mesh film; the mesh film is heated by the first infrared heating zone with a temperature of 130°C to form the second A layer of omentum; open the second spinneret, adjust its internal temperature to 190°C, spinneret speed to 10m / min, air velocity (compressed air) to 120m / min, low melting point hot mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com