Knitting omasum fabric and manufacturing method thereof

A production method, the technology of cow louvers, which is applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of poor hand feeling of sewing thread, high manufacturing cost, and low production efficiency, so as to achieve high production efficiency and reduce production cost , the effect of less process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

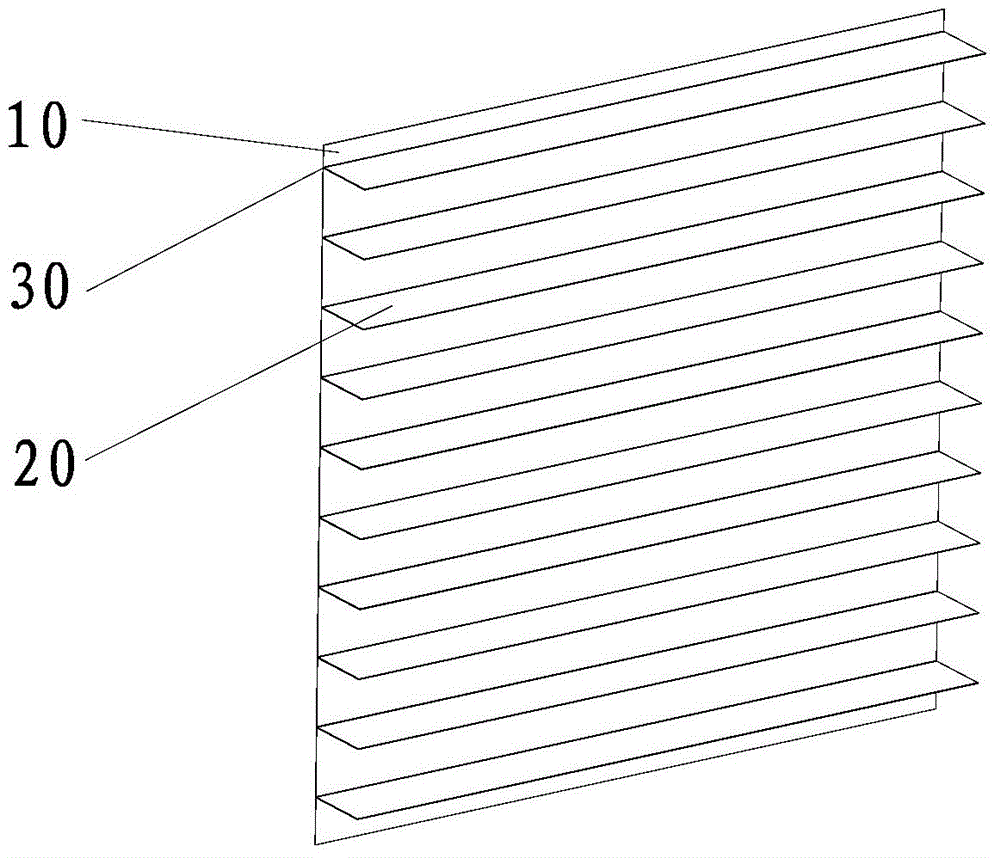

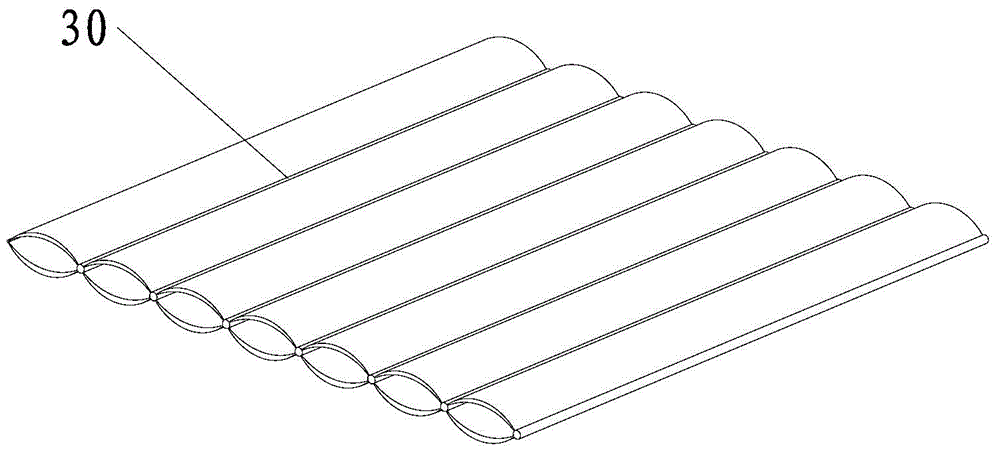

[0028] Such as figure 1 As shown, the knitted cow louver fabric provided in this embodiment includes the base layer 10 and the leaf layer 20, the base layer 10 and the leaf layer 20 can be conventional weaving fabrics, and the yarns used in the braided layer 10 and the leaf layer 20 can also be Choose according to actual needs. Between the base layer 10 and the leaf layer 20, the interlock weave 30 formed by knitting double-sided large circular knitting machine is integrally connected together. The yarn used for weaving the interlock weave 30 is preferably 100D / 72F polyester yarn. Professional technicians can also replace it with other yarns as needed.

[0029] This embodiment also provides a method for making the above-mentioned knitted cow louver fabric, the method comprising the following steps:

[0030] S1: Arranging needles, select a double-sided circular knitting machine with a predetermined number of loop-forming systems. Each knitting system is numbered clockwise or...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that there is only one group of knitting groups in this embodiment, and the double rib weave is knitted in the first and second knitting systems of the double-sided circular knitting machine, and the third knitting system starts The knitting is carried out in the way that all the knitting of the upper needle and the whole knitting of the lower needle are alternated. The yarn used in the knitting system of the last knitting system is 40s water-soluble fiber, and then this group of knitting is cyclically knitted. This embodiment obtains In the knitted cow louver fabric, the distance between two adjacent leaf layers is the same. Other steps in this embodiment are the same as in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com