Dry type etching machine and gathering device for gathering magnetic particles in gas

A dry etching, magnetic particle technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of affecting the smoothness of the gas in the pipeline, reducing the air extraction efficiency and service life of the air extraction device, and improve the air extraction efficiency. and service life, simple structure, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

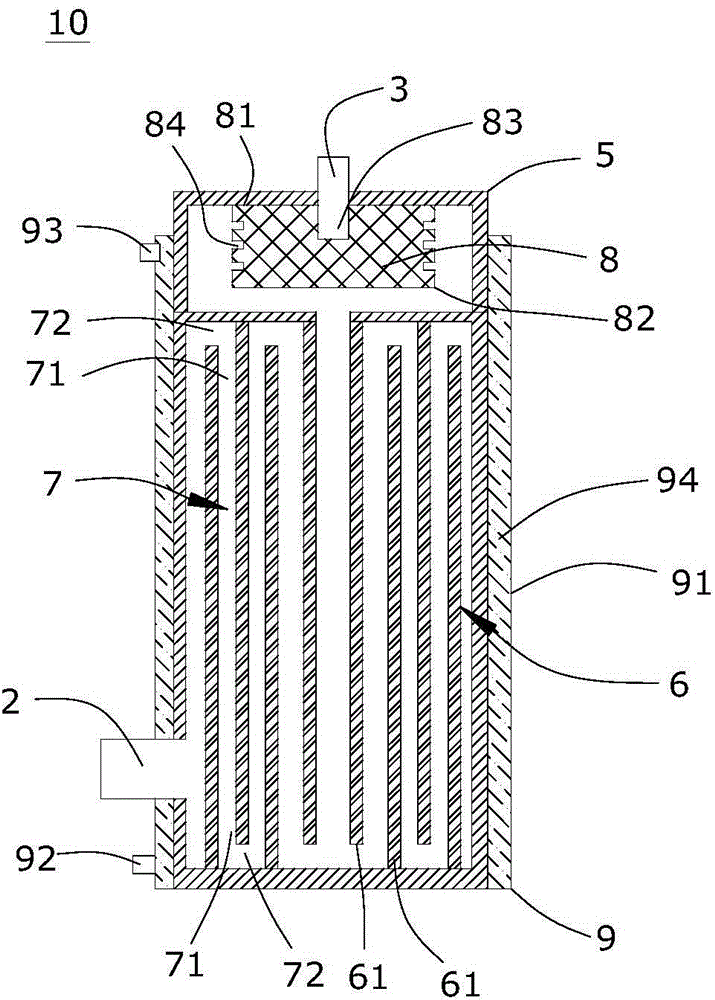

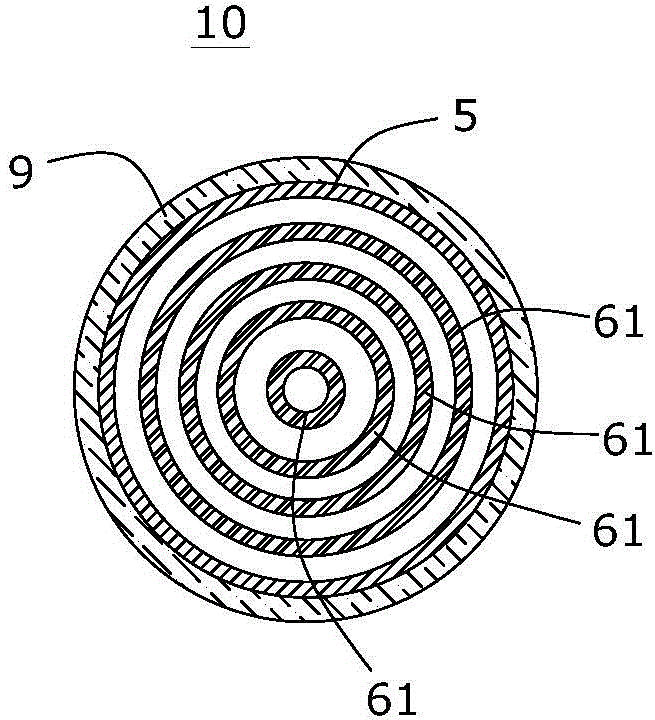

[0026] The present invention will be further described below in conjunction with accompanying drawing.

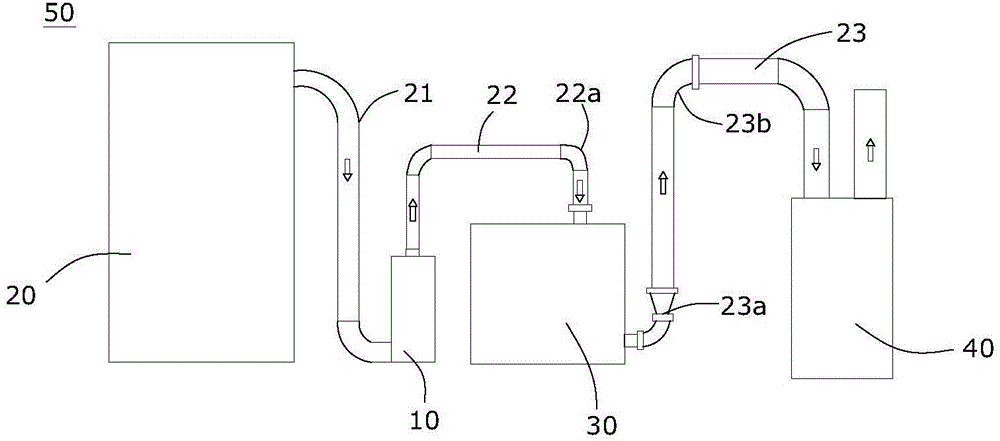

[0027] figure 1 A dry etcher 50 according to the invention is shown. The dry etching machine 50 includes an etching device 20 . When the etching device 20 performs dry etching on a special object to be etched, such as a metal-doped low-temperature polysilicon layer (ie, the semiconductor active layer of the array substrate), a gas with a large amount of magnetic particles will be generated. The main components of the magnetic particles include AlCl3 aluminum trichloride and MoClx molybdenum chloride. These magnetic particles can only show magnetism after magnetization, which can be attracted by magnetic substances, such as electromagnets or permanent magnets.

[0028] At the same time, the dry etching machine 50 also includes a ventilation device 30 capable of extracting gas from the etching device 20 , and a trapping device 10 disposed between the etching device 20 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com