A kind of vanadium-based alloy doped with lithium element and high hydrogen storage capacity and preparation method thereof

An element and hydrogen storage technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of limited effective utilization and industrial application, unsatisfactory cycle stability, and hysteresis of hydrogen absorption and desorption pressure. Achieving broad application prospects and industrial application value, easy implementation, and improved hydrogen storage kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

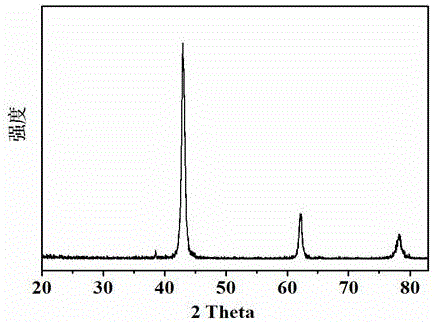

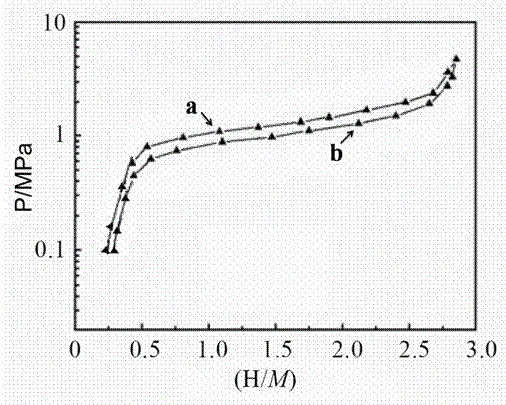

Image

Examples

Embodiment 1

[0017] A vanadium-based alloy with high hydrogen storage capacity doped with lithium, consisting of vanadium-based alloy and Li, with the general formula Ti 5 V 55 Cr 30 m 5 Li 5 , the M-doped metal is a V-Fe alloy with a mass ratio of 1:1; its preparation steps are as follows:

[0018] 1) Preparation of vanadium-based alloy

[0019] After the Ti, V, Cr and doped metal V-Fe alloy with a purity ≥ 99.9wt% are pickled with a hydrochloric acid solution with a concentration of 1mol / L, alkaline washed with a sodium hydroxide solution with a concentration of 1mol / L, and washed with water, Put it into the induction furnace according to the proportion, and melt it into a cast alloy at a temperature of 1800°C under the condition of 0.05MPa high-purity argon atmosphere and magnetic stirring. The melting time is 10 minutes. Carrying out the above-mentioned smelting process, so repeated smelting 3 times until a uniform vanadium-based alloy ingot is obtained;

[0020] 2) Crush the abo...

Embodiment 2

[0026] A vanadium-based alloy with high hydrogen storage capacity doped with lithium, consisting of vanadium-based alloy and Li, with the general formula Ti 7 V 60 Cr 25 m 4 Li 4 , M doping metal is zirconium; the lithium element is mixed with vanadium-based alloy with high hydrogen storage capacity.

[0027] 1) Preparation of vanadium-based alloy

[0028] After the Ti, V, Cr and doped metal zirconium with a purity ≥ 99.9wt% are acid-washed with a hydrochloric acid solution with a concentration of 1mol / L, alkali-washed with a sodium hydroxide solution with a concentration of 1mol / L and washed with water, the Put it into an induction furnace, and melt it into a cast alloy at a temperature of 1900°C under the condition of 0.05MPa high-purity argon atmosphere and magnetic stirring. process, so repeated smelting 3 times until a uniform vanadium-based alloy ingot is obtained;

[0029] 2) Crush the above-mentioned vanadium-based alloy ingot into a powder of less than 200 meshe...

Embodiment 3

[0033] A vanadium-based alloy with high hydrogen storage capacity doped with lithium, consisting of vanadium-based alloy and Li, with the general formula Ti 9 V 65 Cr 20 m 3 Li 3 , The M doping metal is manganese and iron with a mass ratio of 1:2; a vanadium-based alloy with high hydrogen storage capacity mixed with lithium is obtained.

[0034] 1) Preparation of vanadium-based alloy

[0035] After the Ti, V, Cr and doped metal manganese and iron with a purity of ≥99.9wt% are acid-washed with a concentration of 1mol / L hydrochloric acid solution, alkaline-washed with a concentration of 1mol / L sodium hydroxide solution and washed with water, Put it into the induction furnace according to the proportion, in the 0.05MPa high-purity argon atmosphere and under the condition of magnetic stirring, melt it into the cast alloy at a temperature of 1900 ° C, the melting time is 10 minutes, and turn the alloy ingot over after it is water-cooled until it solidifies, and re- Carrying ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com