A kind of thixotropic silicone rubber, its preparation method and its application

A technology of silicone rubber and thixotropy, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting LED luminous efficiency, increasing thixotropic index, and decreasing light transmittance, achieving high thixotropy and thixotropic index High, simple method and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

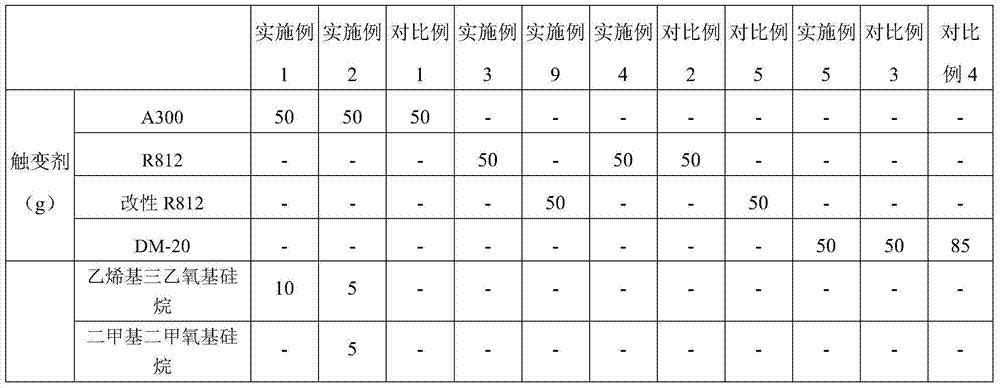

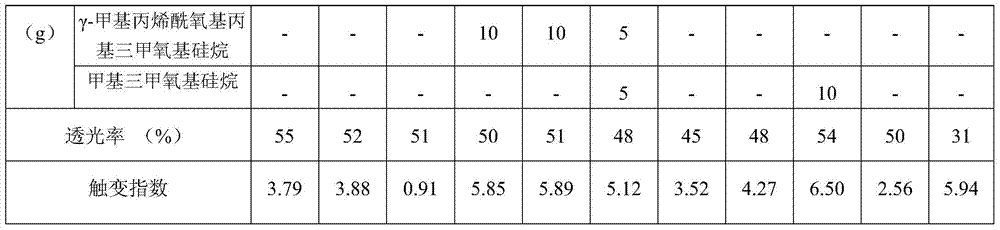

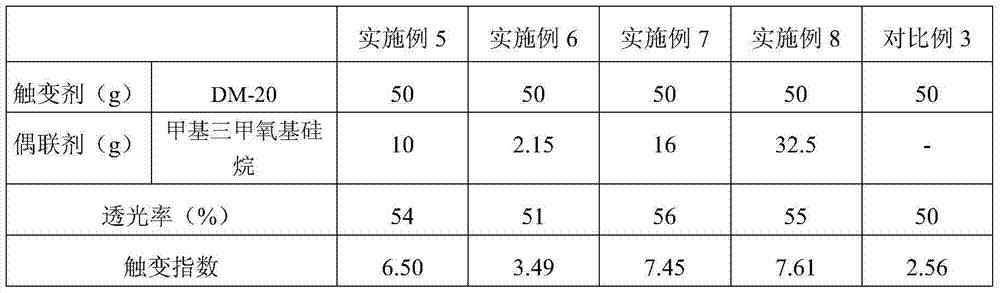

Embodiment 1

[0031] In a 2L reactor, add in order: 10000mPa.s vinyl silicone oil with 0.12% vinyl content, 1000g, 35g hydrogen-containing silicone oil with a viscosity of 100mPa.s and 0.3% hydrogen content, 0.7g ethynyl cyclohexanol, Karstedt platinum catalyst 3ppm, hydrophilic fumed silica (Degussa A300) 50g, vinyltriethoxysilane 10g. Then stir and mix at room temperature (25° C.) for 3 hours to prepare the silicone rubber in the present invention. The silicone rubber has a light transmittance of 55% and a thixotropic index of 3.79. See Table 1 for the data.

Embodiment 2

[0033] In a 2L reactor, add in order: 10000mPa.s vinyl silicone oil with 0.12% vinyl content, 1000g, 35g hydrogen-containing silicone oil with a viscosity of 100mPa.s and 0.3% hydrogen content, 0.7g ethynyl cyclohexanol, Karstedt platinum catalyst 3ppm, hydrophilic fumed silica (Degussa A300) 50g, vinyltriethoxysilane 5g, dimethyldimethoxysilane 5g. Then stir and mix at room temperature for 3 hours to prepare the silicone rubber in the present invention. The silicone rubber has a light transmittance of 52% and a thixotropic index of 3.88. See Table 1 for the data.

Embodiment 3

[0035]In a 2L reactor, add in order: 10000mPa.s vinyl silicone oil with 0.12% vinyl content, 1000g, 35g hydrogen-containing silicone oil with a viscosity of 100mPa.s and 0.3% hydrogen content, 0.7g ethynyl cyclohexanol, Karstedt platinum catalyst 3ppm, hydrophobic fumed silica (Degussa R812) 50g, γ-methacryloxypropyltrimethoxysilane 10g. Then stir and mix at room temperature for 3 hours to prepare the silicone rubber in the present invention. The silicone rubber has a light transmittance of 50% and a thixotropic index of 5.85. See Table 1 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com