Process for preparing light olefin from coal-based synthesis gas and co-producing low-carbon mixed aldehyde

A technology of coal-based synthesis gas and low-carbon olefins, which is applied in the direction of hydrocarbon production from carbon oxides, carbon monoxide reaction preparation, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low mass transfer efficiency in two-phase reactions, Increase the difficulty of phase separation, the separation of phase transfer agents and other issues, to achieve the effect of realizing high-value utilization, solving recycling difficulties, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

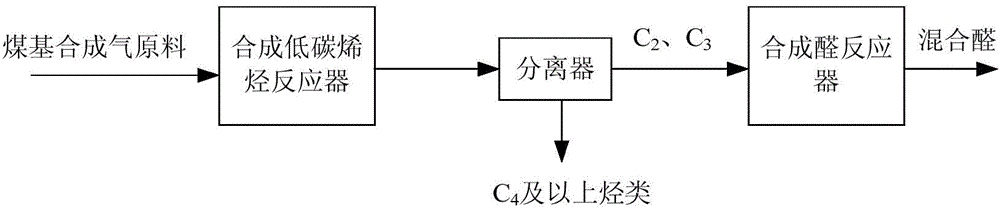

[0047] This embodiment provides a process for co-producing low-carbon mixed aldehydes from coal-based syngas to low-carbon olefins, which includes the following steps:

[0048] H in syngas 2 The / CO volume ratio is 2:1. First, it enters the low-carbon olefin synthesis reactor and contacts with the low-carbon olefin synthesis catalyst. -1 Reduction in hydrogen for 6h; the reaction temperature in the synthesis light olefin reactor is 320°C, the pressure is 2.0MPa, and the reaction space velocity is 1000h -1 ; The mol ratio of the constituent elements of the synthetic low carbon olefin catalyst is Fe:Mn:K:Al 2 o 3 =15:8:2:75; The composition of the outlet gas of the synthesis light olefin reactor is shown in Table 1;

[0049] The outlet tail gas can be separated and removed by the separator to remove C 4 And the above hydrocarbons, the remaining synthesis gas and low-carbon hydrocarbons enter the synthesis aldehyde reactor together with the hydroformylation catalyst for conta...

Embodiment 2

[0052] This embodiment provides a process for co-producing low-carbon mixed aldehydes from coal-based syngas to low-carbon olefins, which includes the following steps:

[0053] H in syngas 2 The / CO volume ratio is 1.8:1. First, it enters the low-carbon olefin synthesis reactor and contacts with the low-carbon olefin synthesis catalyst. -1 Reduction in hydrogen for 5h; the reaction temperature in the synthesis light olefin reactor is 350°C, the pressure is 1.5MPa, and the reaction space velocity is 800h -1 , the molar ratio of the constituent elements of the synthetic low-carbon olefin catalyst is Fe:Mn:K:Al 2 o 3 =20:10:10:60, the gas composition at the outlet of the synthesis light olefin reactor is shown in Table 1;

[0054] The outlet tail gas can be separated and removed by the separator to remove C 4 And the above hydrocarbons, the remaining synthesis gas and low-carbon hydrocarbons enter the synthesis aldehyde reactor together with the hydroformylation catalyst for ...

Embodiment 3

[0056] This embodiment provides a process for co-producing low-carbon mixed aldehydes from coal-based syngas to low-carbon olefins, which includes the following steps:

[0057] H in syngas 2 The / CO volume ratio is 2:1. First, it enters the low-carbon olefin synthesis reactor and contacts with the low-carbon olefin catalyst. -1 Reduction in hydrogen for 8h; the reaction temperature in the synthesis light olefin reactor is 350°C, the pressure is 1.5MPa, and the reaction space velocity is 1200h -1 , the molar ratio of the constituent elements of the synthetic low-carbon olefin catalyst is Fe:Mn:K:Al 2 o 3 =28:8:15:49; The gas composition at the outlet of the synthesis light olefin reactor is shown in Table 1;

[0058] The outlet tail gas can be separated and removed by the separator to remove C 4And the above hydrocarbons, the remaining synthesis gas and low-carbon hydrocarbons enter the synthesis aldehyde reactor and contact with the hydroformylation catalyst. The reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com