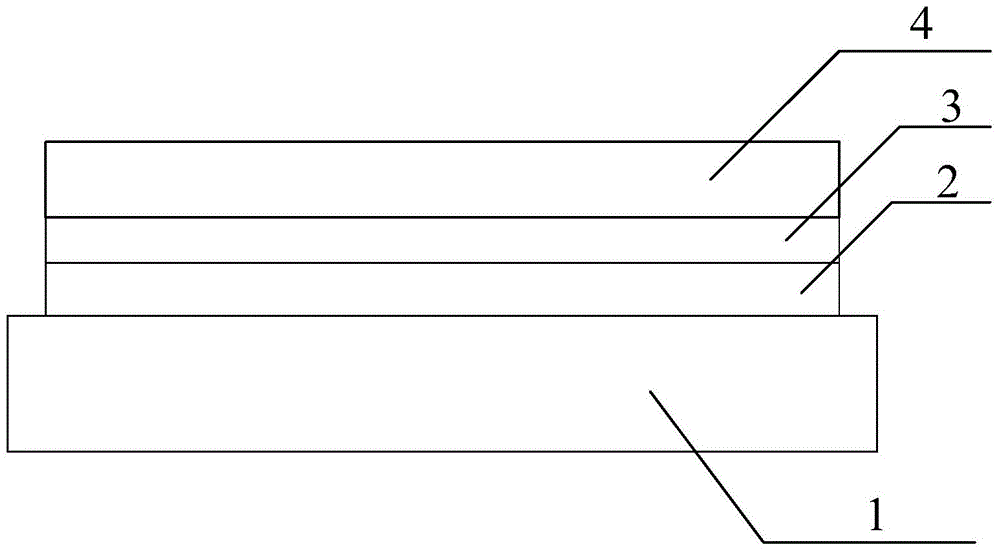

Flexible film

A technology of flexible film and flexible substrate, applied in the field of flexible film, can solve the problems of easy oxidation of silver, increased cost, and complex material structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put the 23u PET coil in the unwinding chamber, replace the winding chamber with a new core, clean the chamber, replace the protective plate, and wait for the vacuum to -6 Mbar started production; under the protection of argon, the gas flow rate is 400sccm~500sccm, the chamber uses NiCr target material, medium frequency power (MF power) discharge, so that NiCr is sputtered on the PET surface, so that the thickness of the NiCr layer is 10nm; then the chamber The chamber uses a Cu alloy target. Under the protection of argon gas, the gas flow rate is 400-500 sccm, and the MF power discharges to sputter a 10nm CuSn layer on the surface of the NiCr layer. Finally, the chamber is replaced with a NiCr target material. Under the protection of argon gas, The gas flow rate is 400-500 sccm, and the MF power is discharged, so that the thickness of the NiCr layer is 17 nm, and a flexible film is obtained.

[0039] The performance of the flexible film was detected according to the ASTM...

Embodiment 2

[0041] Put the 23u PET coil in the unwinding chamber, replace the winding chamber with a new core, clean the chamber, replace the protective plate, and wait for the vacuum to -6 Mbar started production; under the protection of argon, the gas flow rate is 400sccm~500sccm, the chamber uses NiCr target material, medium frequency power (MF power) discharge, so that NiCr is sputtered on the PET surface, so that the thickness of the NiCr layer is 15nm; then the chamber The chamber uses a Cu alloy target. Under the protection of argon, the gas flow rate is 400-500 sccm, and the MF power discharges to sputter a 15nm CuSn layer on the surface of the NiCr layer. Finally, the chamber is replaced with a NiCr target. Under the protection of argon, The gas flow rate is 400-500 sccm, and the MF power is discharged to make the thickness of the NiCr layer 20nm to obtain a flexible film.

[0042] The performance of the flexible film was detected according to the ASTMD1003 standard. The experimen...

Embodiment 3

[0044] Put the 23u PET coil in the unwinding chamber, replace the winding chamber with a new core, clean the chamber, replace the protective plate, and wait for the vacuum to -6 Mbar started production; under the protection of argon, the gas flow rate is 400sccm~500sccm, the chamber uses NiCr target material, medium frequency power (MF power) discharge, so that NiCr is sputtered on the PET surface, so that the thickness of the NiCr layer is 12nm; then the chamber The chamber uses a Cu alloy target. Under the protection of argon gas, the gas flow rate is 400-500 sccm, and the MF power discharges, so that the surface of the NiCr layer is sputtered with a 12nm CuSn layer. Finally, the chamber is replaced with a NiCr target material. Under the protection of argon gas, The gas flow rate is 400-500 sccm, and the MF power is discharged to make the thickness of the NiCr layer 18nm to obtain a flexible film.

[0045] The performance of the flexible film was detected according to the AST...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com