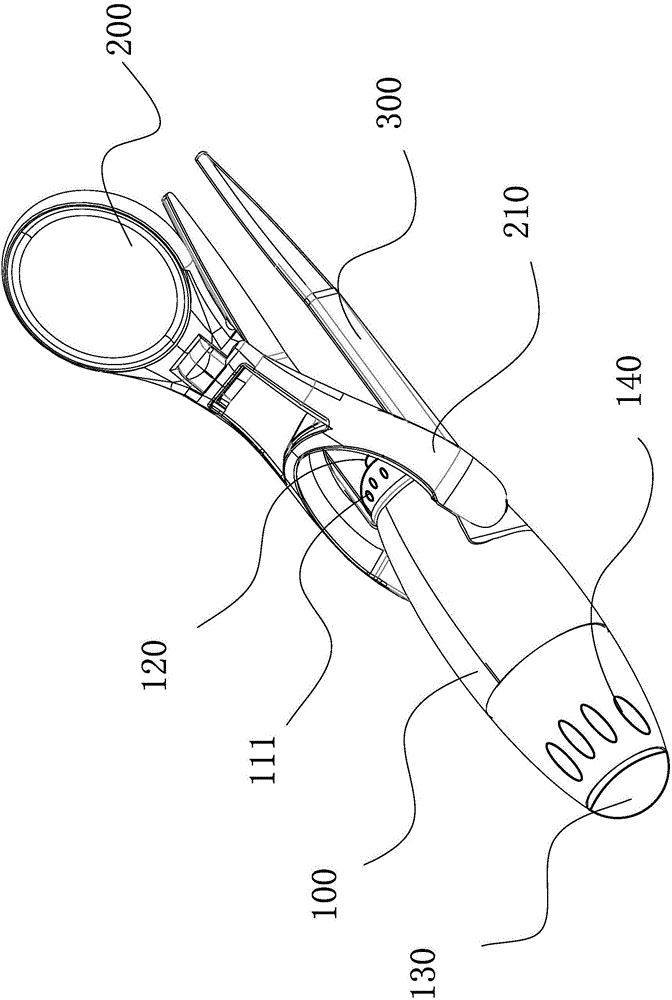

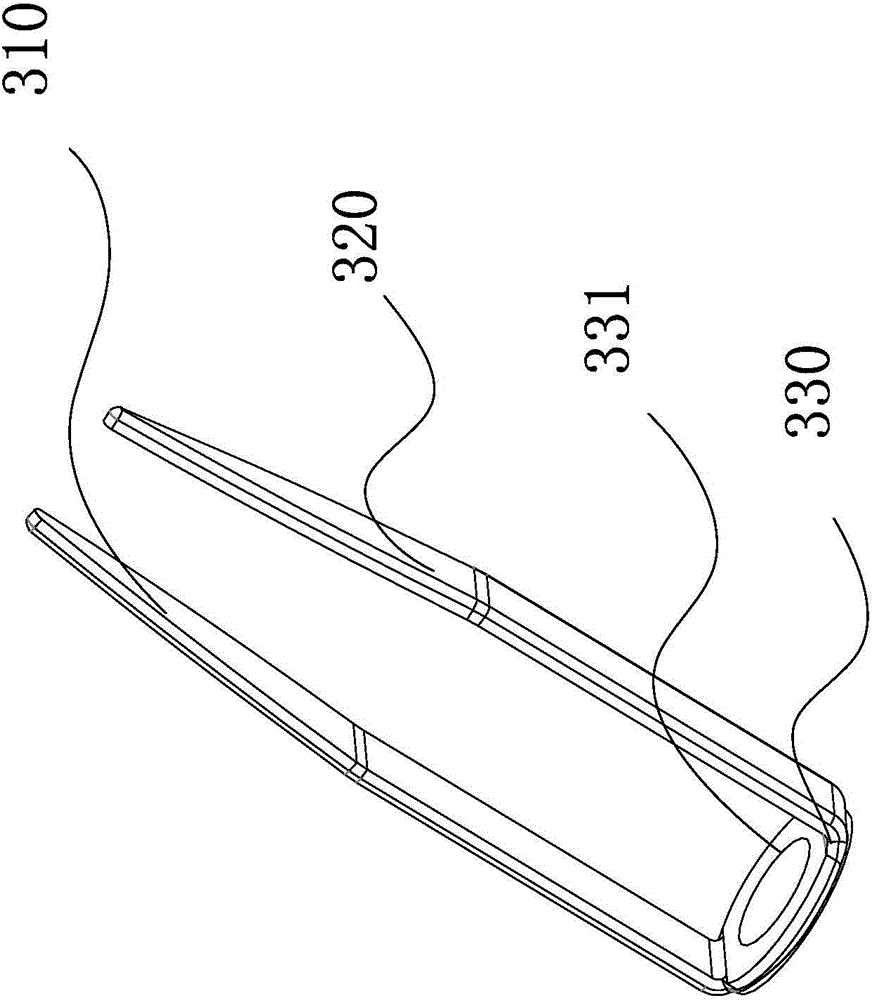

Multifunctional philatelic tool

A multi-functional and tool technology, applied in the field of entertainment products, can solve the problems that magnifying glass and tweezers cannot be used at the same time, complicated use, etc., and achieve the effect of long service life, extended service life and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

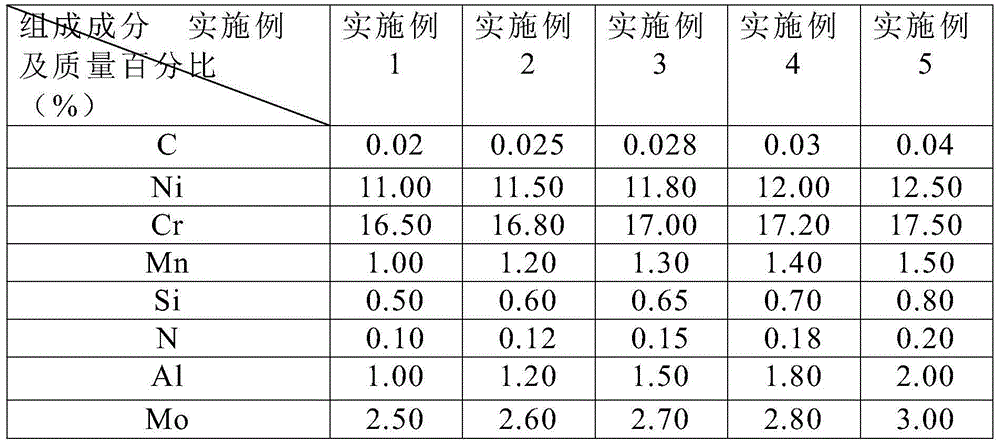

Embodiment 1

[0042] According to the composition and mass percentage of the stainless steel used in the tweezers described in Example 1 in Table 1, the ingredients were heated to 650°C and kept warm for later use.

[0043] First vacuumize the vacuum furnace to 5.0Pa, then add the iron, nickel and aluminum in the above preheated ingredients into the vacuum furnace for melting at 1530°C, and continue to add silver, copper and intermediate alloys after they are completely melted , after complete melting, molten steel is obtained and stirred evenly; wherein said iron is industrial pure iron, nickel is pure nickel, aluminum is industrial aluminum ingot, copper is electrolytic copper, silver is pure silver, and the intermediate alloy has a carbon content of 0.15%. -0.3% low-carbon ferrochrome, low-carbon ferromanganese with a carbon content of 0.20%-0.40%, ferromanganese nitride with a nitrogen content of 2.50%-4.0%, ferrosilicon alloys with a silicon content of 60%-75%, molybdenum Ferro-molybde...

Embodiment 2

[0047] According to the composition and mass percentage of the stainless steel used in the tweezers described in Table 1 and Example 2, the ingredients were heated to 670° C. and kept warm for later use.

[0048] First vacuumize the vacuum furnace to 6.0Pa, then add the iron, nickel and aluminum in the above preheated ingredients into the vacuum furnace for melting at 1530°C, and continue to add silver, copper and intermediate alloys after they are completely melted , after complete melting, molten steel is obtained and stirred evenly; wherein said iron is industrial pure iron, nickel is pure nickel, aluminum is industrial aluminum ingot, copper is electrolytic copper, silver is pure silver, and the intermediate alloy has a carbon content of 0.15%. -0.3% low-carbon ferrochrome, low-carbon ferromanganese with a carbon content of 0.20%-0.40%, ferromanganese nitride with a nitrogen content of 2.50%-4.0%, ferrosilicon alloys with a silicon content of 60%-75%, molybdenum Ferro-moly...

Embodiment 3

[0052] According to the composition and mass percentage of the stainless steel used in the tweezers described in Table 1, Example 3, the ingredients were heated to 680°C and kept warm for later use.

[0053] First vacuumize the vacuum furnace to 6.5Pa, then add the iron, nickel and aluminum in the above preheated ingredients into the vacuum furnace for melting at 1540°C, and continue to add silver, copper and intermediate alloys after they are completely melted , after complete melting, molten steel is obtained and stirred evenly; wherein said iron is industrial pure iron, nickel is pure nickel, aluminum is industrial aluminum ingot, copper is electrolytic copper, silver is pure silver, and the intermediate alloy has a carbon content of 0.15%. -0.3% low-carbon ferrochrome, low-carbon ferromanganese with a carbon content of 0.20%-0.40%, ferromanganese nitride with a nitrogen content of 2.50%-4.0%, ferrosilicon alloys with a silicon content of 60%-75%, molybdenum Ferro-molybdenu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com