Automatic feeding device for tableware punching

An automatic feeding and tableware technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of easy danger, slow speed, low processing precision, etc., to reduce manual operation, improve safety performance, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

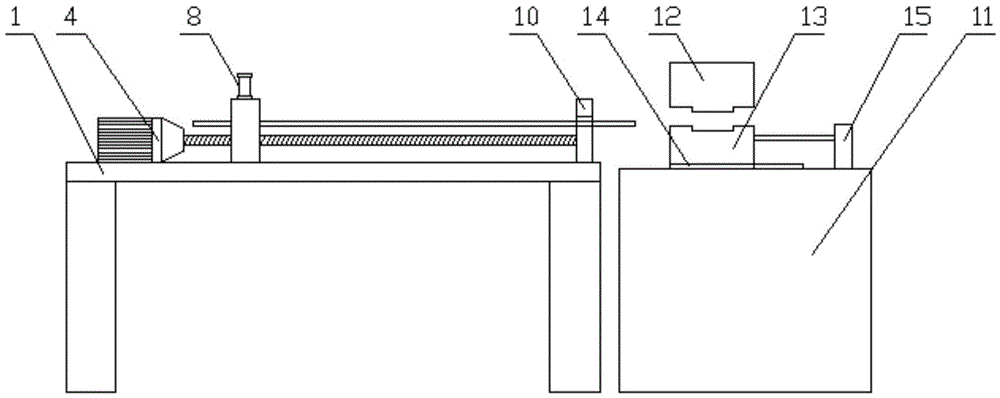

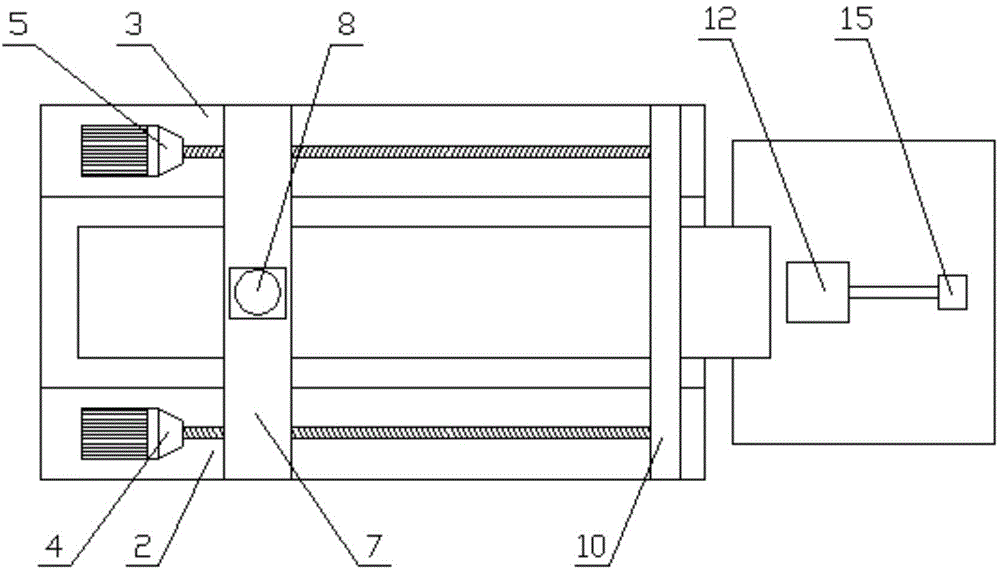

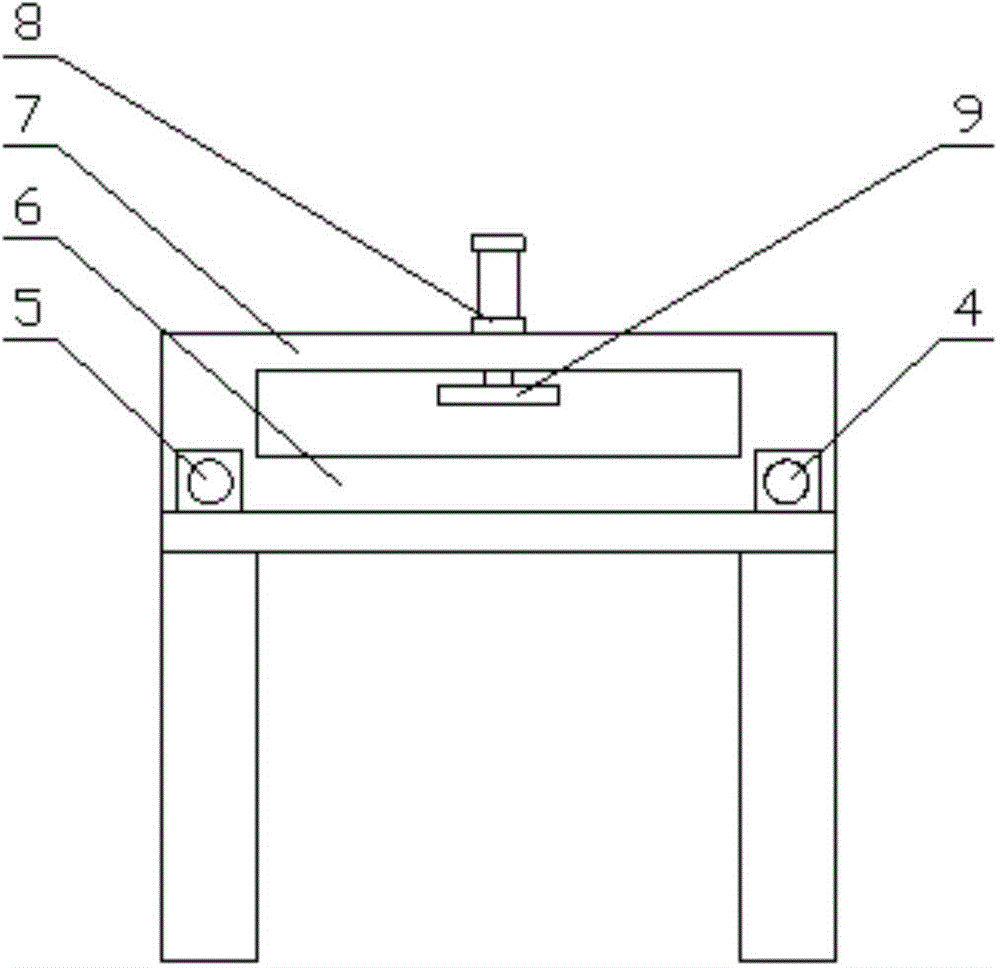

[0021] like Figure 1-Figure 4 As shown in the structural diagram of the present invention, the present invention provides an automatic feeding device for tableware punching, which includes a pushing mechanism, a clamping mechanism, a guiding mechanism and a punching mechanism arranged in sequence, and the pushing mechanism includes a bracket 1, and the bracket 1 It includes a front cross frame 2 and a rear cross frame 3, and a front motor 4 and a rear motor 5 are respectively arranged on the top surfaces of the front cross frame 2 and the rear cross frame 3. The clamping mechanism includes a bottom plate 6 and a support plate 7, and the bottom plate 6 and the support plate 7 surround a horizontal feeding port, the two ends of the base plate are screwed with the output shafts of the front motor 4 and the rear motor 5, and a compression cylinder 8 is arranged above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com