A flotation collector for fluorite ore

A collector and fluorite ore technology, applied in the field of fluorite ore flotation collector, can solve the problems of poor selectivity, low concentrate grade, large index fluctuation, etc., to improve grade and recovery rate, water solubility and Good dispersion and stable flotation foam properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

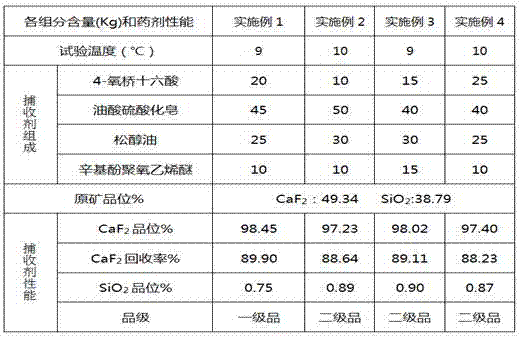

Embodiment 1

[0014] The composition of the raw materials of this embodiment: The raw materials are 20 parts of 4-oxohexadecanoic acid, 45 parts of oleic acid sulfated soap, 25 parts of terpineol oil, and 10 parts of octylphenol polyoxyethylene ether.

[0015] The preparation process of oleic acid sulfated soap is:

[0016] Using oleic acid as the basic raw material, add concentrated sulfuric acid with 10%-20% oleic acid mass to it for 40-90 minutes for esterification reaction, the concentration of the concentrated sulfuric acid is not less than 88%; after the esterification reaction is completed, add to the reaction product Add caustic soda for neutralization, adjust the pH value to 7.0-7.5, and react for 1 to 1.5 hours to obtain oleic acid sulfated soap.

[0017] The preparation method of fluorite ore flotation collector is:

[0018] Add the terpineol oil and octylphenol polyoxyethylene ether to the oleic acid sulfated soap according to the above ratio, and stir the reaction at room temperature f...

Embodiment 2

[0020] The composition of the raw materials in this embodiment: The raw materials are 10 parts of 4-oxohexadecanoic acid, 50 parts of oleic acid sulfated soap, 30 parts of terpineol oil, and 10 parts of octylphenol polyoxyethylene ether.

[0021] The preparation process of oleic acid sulfated soap is:

[0022] Using oleic acid as the basic raw material, add concentrated sulfuric acid of 10%-20% oleic acid mass to it for 40-90 minutes for esterification reaction, the concentration of concentrated sulfuric acid is not less than 88%; after the esterification reaction is completed, add to the reaction product Add caustic soda for neutralization, adjust the pH value to 7.0-7.5, and react for 1 to 1.5 hours to obtain oleic acid sulfated soap.

[0023] The preparation method of fluorite ore flotation collector is:

[0024] Add the terpineol oil and octylphenol polyoxyethylene ether to the oleic acid sulfated soap according to the above ratio, and stir the reaction at room temperature for 0.5...

Embodiment 3

[0026] The composition of the raw materials of this embodiment: The raw materials are 15 parts of 4-oxohexadecanoic acid, 40 parts of oleic acid sulfated soap, 30 parts of terpineol oil, and 15 parts of octylphenol polyoxyethylene ether.

[0027] The preparation process of oleic acid sulfated soap is:

[0028] Using oleic acid as the basic raw material, add concentrated sulfuric acid of 10%-20% oleic acid mass to it for 40-90 minutes for esterification reaction, the concentration of concentrated sulfuric acid is not less than 88%; after the esterification reaction is completed, add to the reaction product Add caustic soda for neutralization, adjust the pH value to 7.0-7.5, and react for 1 to 1.5 hours to obtain oleic acid sulfated soap.

[0029] The preparation method of fluorite ore flotation collector is:

[0030] Add terpineol oil and octylphenol polyoxyethylene ether to the oleic acid sulfated soap according to the above ratio, and stir and react at room temperature for 0.5 to 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com