Preparation method of ferromagnetic nanoparticle supported rhodium complex hydroformylation catalyst

A hydroformylation catalyst and nanoparticle technology are applied in the field of preparation of hydroformylation catalysts and can solve the problems of catalyst decomposition and deactivation, increased difficulty of phase separation, low mass transfer efficiency of two-phase reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

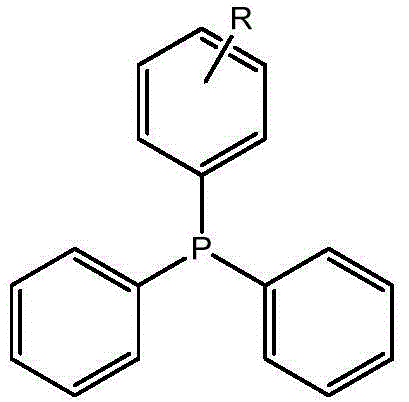

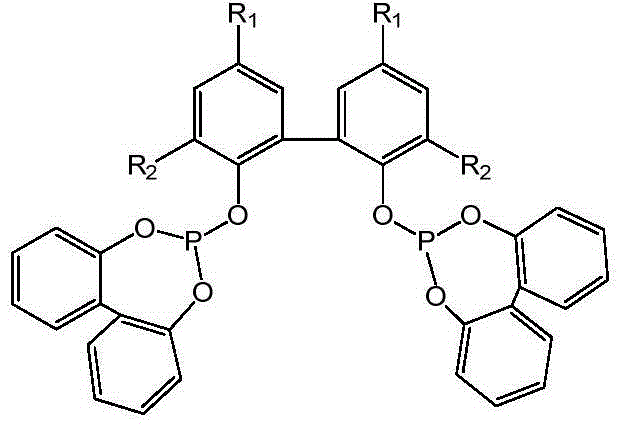

[0072] This embodiment provides a trans-RhCl(CO)(PPh 3 ) 2 Preparation of superparamagnetic Fe for active components 3 o 4-RhCl(CO)(PPh 3 ) 2 Nano catalyst, it is prepared by the following steps:

[0073] Step 1, preparation of superparamagnetic nanoparticles

[0074] 0.4mL Fe(CO) 5 (3mmol), 1mL (3.3mmol) oleic acid, and 20mL TOA were placed in a three-necked flask with a volume of 100mL; heated to 280°C under the protection of Ar, and reacted for 2 hours to obtain a black solution. After removing impurities, superparamagnetic Fe 3 o 4 magnetic nanoparticles.

[0075] Step 2, with trans-RhCl(CO)(PPh 3 ) 2 Preparation of SPION-Rh Nanocatalysts as Active Components

[0076] 20mg superparamagnetic Fe 3 o 4 Disperse the nanoparticles in 50mL of toluene, add 100mg of 4-aminophthalic acid, and reflux at 80°C for 2 hours, so that the bidentate carboxyl ligands can fully replace the original oleic acid ligands on the surface of the magnetic nanoparticles; Magnetic nanopa...

Embodiment 2

[0082] This embodiment provides a trans-RhCl(CO)(PPh 3 ) 2 Preparation of SiO for active components 2 coated superparamagnetic Fe 3 o 4 -SiO 2 -Rh nanocatalyst, it is prepared by the following steps:

[0083] Step 1, preparation of superparamagnetic nanoparticles

[0084] 0.4mL Fe(CO) 5 (3mmol), 1mL (3.3mmol) oleic acid and 20mL TOA were placed in a three-necked flask with a volume of 100mL; heated to 280°C under the protection of Ar, and reacted for 2 hours to obtain a black solution, and after removing impurities, superparamagnetic Fe 3 o 4 magnetic nanoparticles.

[0085] Step 2, preparation of superparamagnetic nanoparticles coated with silica

[0086] Prepare 100mL of superparamagnetic Fe with a concentration of 0.05mg / mL 3 o 4 Chloroform solution A of nanoparticles; place chloroform solution A at 40°C, and concentrate the solution to 10 μL by distillation under reduced pressure at a speed of 150 rpm; add 100 mL of sodium dodecylsulfonate with a concentration o...

Embodiment 3

[0093] This embodiment provides a Rh(CO)(PPh 3 )(acac) as the active component to prepare superparamagnetic Fe 3 o 4 -Rh nano-catalyst, its preparation method is the same as embodiment 1, and difference is that rhodium complex is changed into Rh(CO)(PPh 3 )(acac).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com