A chemical raw material microwave concentration device and concentration method thereof

A technology for chemical raw materials and concentration devices, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of secondary environmental pollution, pipeline blockage of concentration equipment, and gas emissions in the environment, so as to reduce environmental pollution. Emissions, reduced waste content, reduced concentration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

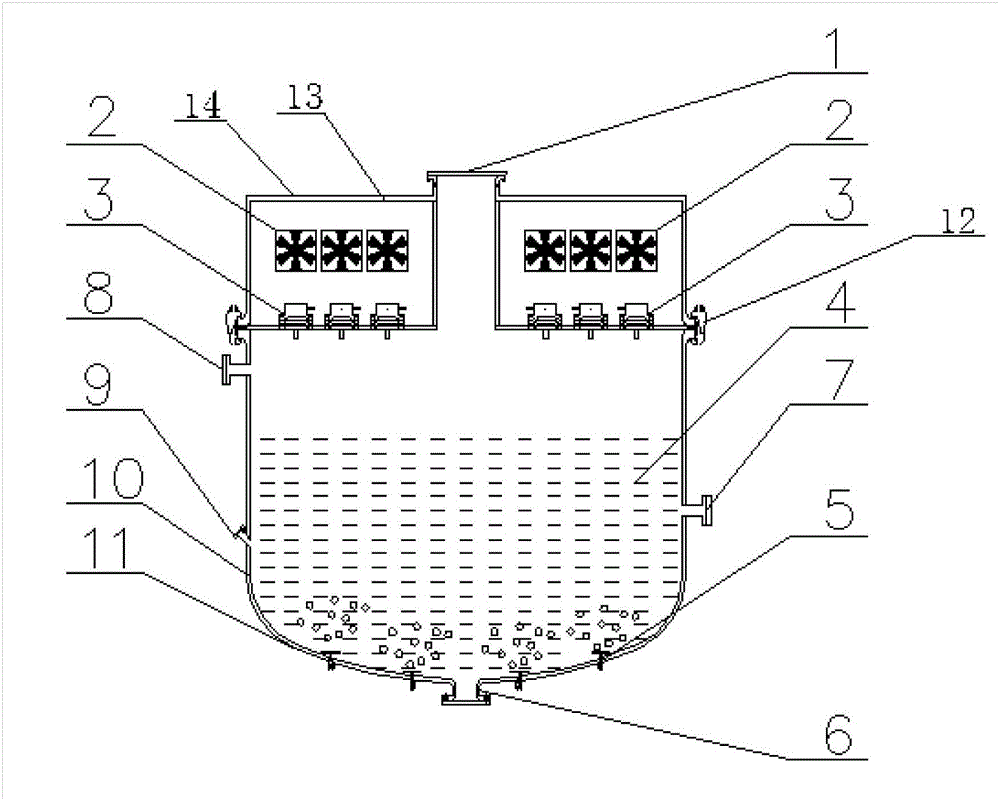

[0030] Such as figure 1 As shown, a microwave concentration device for chemical raw materials includes a reactor and a heat dissipation unit 13, wherein the reactor consists of a reaction shell 11, a liquid discharge port 6 arranged at the bottom end of the reaction shell 11, and an air outlet 1 arranged at the top end of the reaction shell 11. The bubble generating mechanism 5 provided on the left and right sides of the liquid discharge port 6, the feed port 8 provided in the upper part of the reaction shell 11, the temperature control unit 9 provided at the lower end of the feed port 8, and the temperature control unit 9 is provided on the opposite side The sampling port 7 and the inner lining 10 in the reaction shell 11; the heat dissipation unit 13 is composed of a heat dissipation fan 2 arranged inside the heat dissipation unit 13 and a heat dissipation shell 14 wrapped outside the heat dissipation unit 13; the heat dissipation unit 13 and the reactor The heat dissipation ...

Embodiment 2

[0044] The method for microwave concentration of chemical raw materials using a chemical raw material microwave concentration device includes the following steps:

[0045] (1) Feeding: Add 1% of the dilute chemical raw materials into the reactor through the pump through the feed port 8. Turn on the bubble generating mechanism 5, so that the bubble generating mechanism 5 generates bubbles at the bottom of the reactor. The blast volume is 1m 3 / min, stir the chemical raw material solution in the reaction kettle through the impulse of bubbles, and set it aside;

[0046] (2) Concentration: The concentration step of the chemical raw materials to be used in step 1) is divided into one-step concentration and two-step concentration. In the one-step concentration, a microwave generator 3 is used to emit microwaves with a frequency of 300MHz into the chemical raw material solution and adjust The temperature of the solution is 40°C, microwave treatment is 30min; then the emission frequency of...

Embodiment 3

[0050] The method for microwave concentration of chemical raw materials using a chemical raw material microwave concentration device includes the following steps:

[0051] (1) Feeding: add 20% of the dilute chemical raw materials into the reactor through the pump from the feed port 8 and turn on the bubble generating mechanism 5 so that the bubble generating mechanism 5 generates bubbles at the bottom of the reactor. The blast volume is 6m 3 / min, stir the chemical raw material solution in the reactor through the impulse of bubbles, and set it aside;

[0052] (2) Concentration: The concentration step of the chemical raw materials to be used in step 1) is divided into one-step concentration and two-step concentration. In the one-step concentration, a microwave generator 3 is used to emit microwaves with a frequency of 3000 MHz into the chemical raw material solution and adjust The temperature of the solution is 60°C, microwave treatment for 1 min; then adjust the emission frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com