Gingko beverage and preparation method thereof

A technology of ginkgo biloba, beverages, applied in the direction of bacteria used in food preparation, functions of food ingredients, food science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

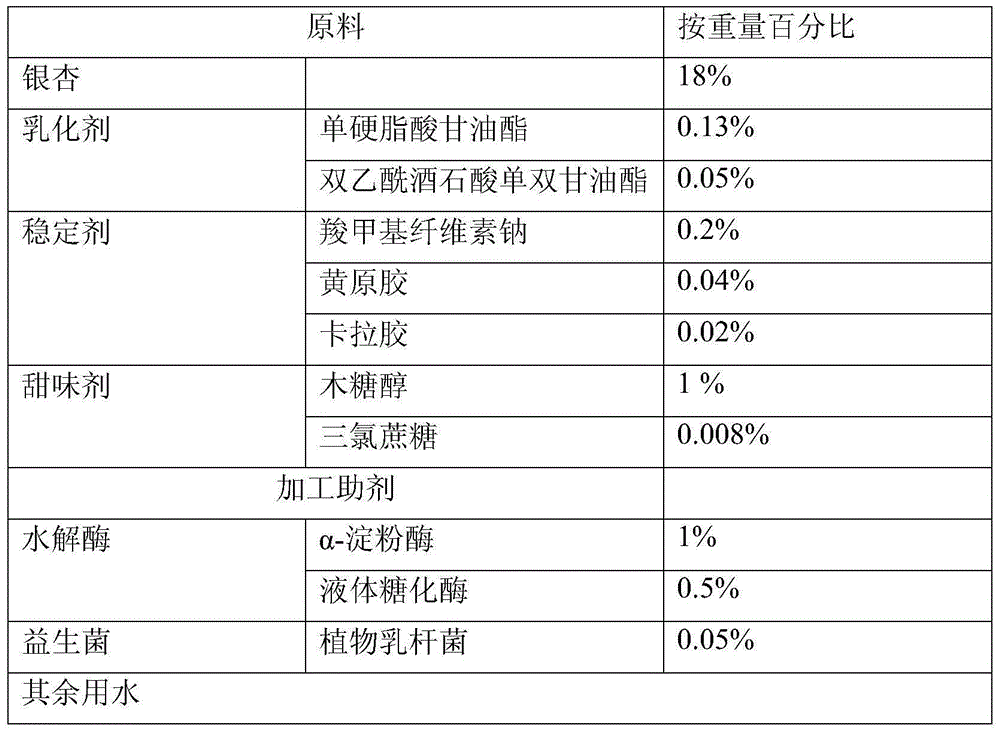

Image

Examples

Embodiment 1

[0045]

[0046] 1) Pretreatment of Ginkgo biloba: Accurately weigh the Ginkgo biloba after shelling, add to boiling water, boil for 15 minutes, remove the endocarp and wash with water;

[0047] 2) Preparation of slurry: take the processed Ginkgo biloba according to the formula, add 5 times the volume of water, and use a refiner for coarse grinding. The coarse abrasive liquid is finely ground twice through a colloid mill to obtain slurry A. The measured viscosity is 265mpa .s (rotor No. 1, 6rpm, 25°C), the starch content is greater than 30.0g / L;

[0048] 3) Enzymolysis: Add α-amylase to slurry A, enzymolyze at 65°C for 60 minutes, then add liquid glucoamylase, enzymolyze at 60°C for 120 minutes, inactivate enzyme at 92°C for 8 minutes after enzymolysis, and obtain enzymolysis material B, measure Viscosity is 50mpa.s (No. 1 rotor, 6rpm, 25°C);

[0049] 4) Filtration: Enzymolysis material liquid B is firstly filtered through a 80-mesh sieve, and then finely filtered through a...

Embodiment 2

[0058] The liquid glucoamylase in the hydrolytic enzyme in Example 1 was removed, and the others were prepared in the same manner as in Example 1. The viscosity of slurry A was measured to be 268mpa.s (rotor No. 1, 6rpm, 25°C), and the starch content was greater than 30.0g / L; the viscosity of feed liquid B is 58mpa.s (No. 1 rotor, 6rpm, 25°C); the starch content in feed liquid C is less than 5.0g / L, the total sugar content is more than 30.0g / L, and the protein content is about 0.35g / 100ml.

Embodiment 3

[0060]

[0061] 1) Ginkgo pretreatment: accurately weigh the shelled ginkgo, add it to boiling water, boil for 10 minutes, remove the endocarp and wash it with water;

[0062] 2) Preparation of slurry: take the processed Ginkgo biloba according to the formula, add 6 times the volume of water, and use a refiner to perform coarse grinding, and the coarse abrasive liquid is finely ground twice through a colloid mill to obtain slurry A, and the measured viscosity is 213mpa .s (rotor No. 1, 6rpm, 25°C), the starch content is greater than 25.0g / L;

[0063] 3) Enzymolysis: Add α-amylase to slurry A, enzymolyze at 60°C for 60 minutes, then add liquid glucoamylase, enzymolyze at 62°C for 120 minutes, and inactivate enzyme at 90°C for 10 minutes after enzymolysis to obtain enzymolysis material B, measure Viscosity is 53mpa.s (No. 1 rotor, 6rpm, 25°C);

[0064] 4) Filtration: Enzymolysis feed solution B is firstly filtered through a 100-mesh sieve, and then finely filtered through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com