Tea residue feed additive and preparation method thereof

A feed additive and tea dregs technology, which is applied in the field of tea dregs feed additive and its preparation, can solve the problems of increasing production costs, occupying space, and polluting the environment, and achieve the goal of not occupying a lot of space, low cost, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

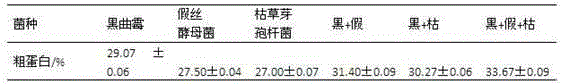

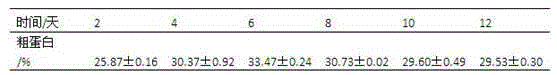

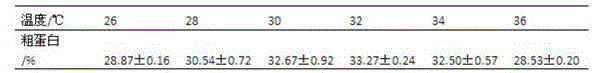

Examples

Embodiment 1

[0039] Example 1: Preparation method of tea residue feed additive

[0040] A preparation method of tea dregs feed additive includes the following steps:

[0041] (1) Material preparation: The raw material of tea dregs is the residue after extracting effective ingredients from tea leaves, baked to moisture content ≤ 8%, and ready for use; the tea leaves are green tea, black tea, white tea, oolong tea, jasmine tea...;

[0042] (2) Preparation of PDA liquid medium: first wash and peel the potatoes, then weigh 200g potatoes and cut them into small pieces, add water to boil (boil for 20-30 minutes, can be pierced by a glass rod), use eight layers of gauze Filter, heat, add 20g glucose, stir evenly, add water to 1000ml after a little cooling, divide into Erlenmeyer flasks, stopper, (121℃) sterilize for about 20min, take out, cool and store for later use.

[0043] (3) Bacterial solution preparation: inoculate the slant strains of Aspergillus niger, Bacillus subtilis, and Candida spp. into th...

Embodiment 2

[0048] Example 2: A preparation method of tea residue feed additive

[0049] A preparation method of tea dregs feed additive includes the following steps:

[0050] (1) Material preparation: The raw material of tea dregs is the residue after extracting effective ingredients from tea leaves, baked to moisture content ≤ 8%, and ready for use; the tea leaves are green tea, black tea, white tea, oolong tea, jasmine tea...;

[0051] (2) Preparation of PDA liquid medium: first wash and peel the potatoes, then weigh 200g potatoes and cut them into small pieces, add water to boil (boil for 20-30 minutes, can be pierced by a glass rod), use eight layers of gauze Filter, heat, add 20g glucose, stir evenly, add water to 1000ml after a little cooling, divide into Erlenmeyer flasks, stopper, (121℃) sterilize for about 20min, take out, cool and store for later use.

[0052] (3) Preparation of bacterial suspension: inoculate the slant strains of Aspergillus niger, Bacillus subtilis, and Candida respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com