Method for manufacturing heating element with surface coating

A manufacturing method and surface coating technology, applied in the direction of coating, electric heating device, ohmic resistance heating, etc., can solve the problems of far-infrared rays and quantum energy not easy to diverge, paint mixing or strength reduction, etc., and achieve storage stability and stability Will reduce, improve storage, improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

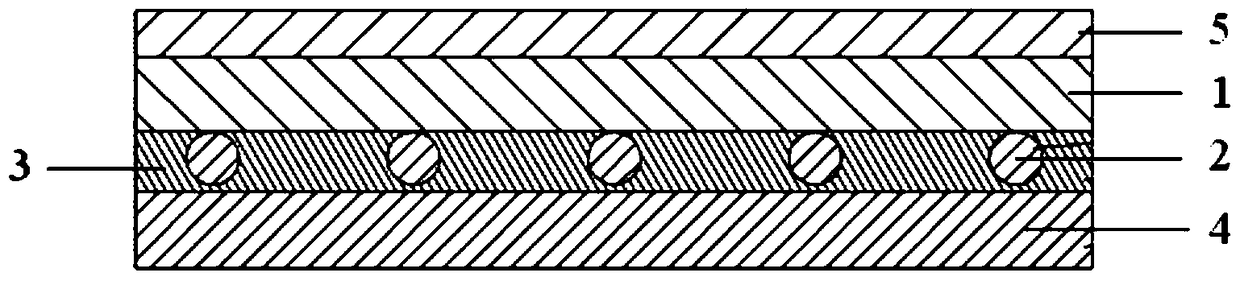

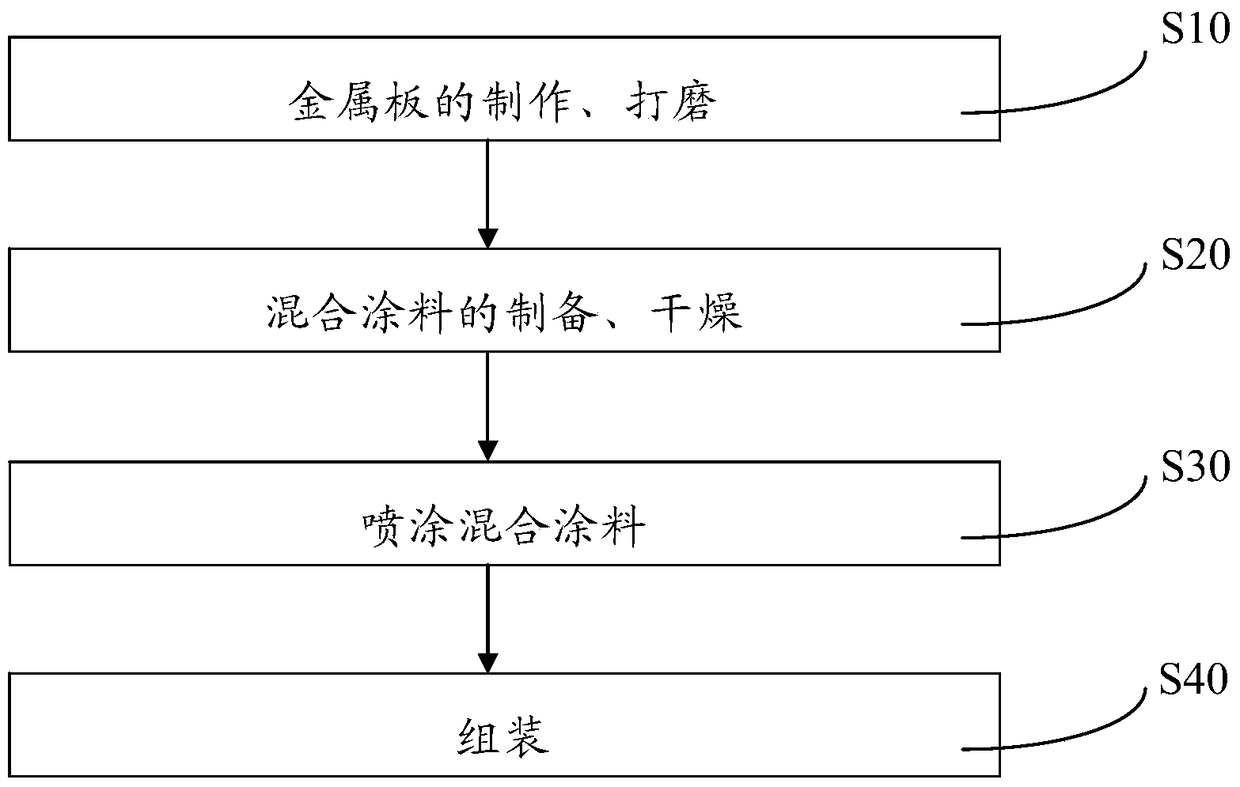

[0034] see figure 1 In the embodiment of the present invention, the heating body includes a coating, a metal plate, a heating coil, silver foil paper and a sealing part, see figure 2 , the manufacturing method includes the following steps:

[0035] S10. Make a metal plate with metal material, and process the surface of the metal plate into a rough surface through a grinding process, so that it emits a large amount of far-infrared rays and quantum energy.

[0036] S20, preparation of mixed paint:

[0037] S21. Mix the silica series adhesive with deionized water, stir for more than 3 hours, then add isopropanol and silane coupling agent, and mix for more than 24 hours to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com